Cavity filling hydraulic inorganic powdery foam material, as well as application thereof

A technology of inorganic powder and foaming materials, which is applied in the field of powder foaming materials, can solve the problems of complex operation process and slow development of material strength, and achieve the effects of simplified molding process, simple and convenient application and operation, and fast consolidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

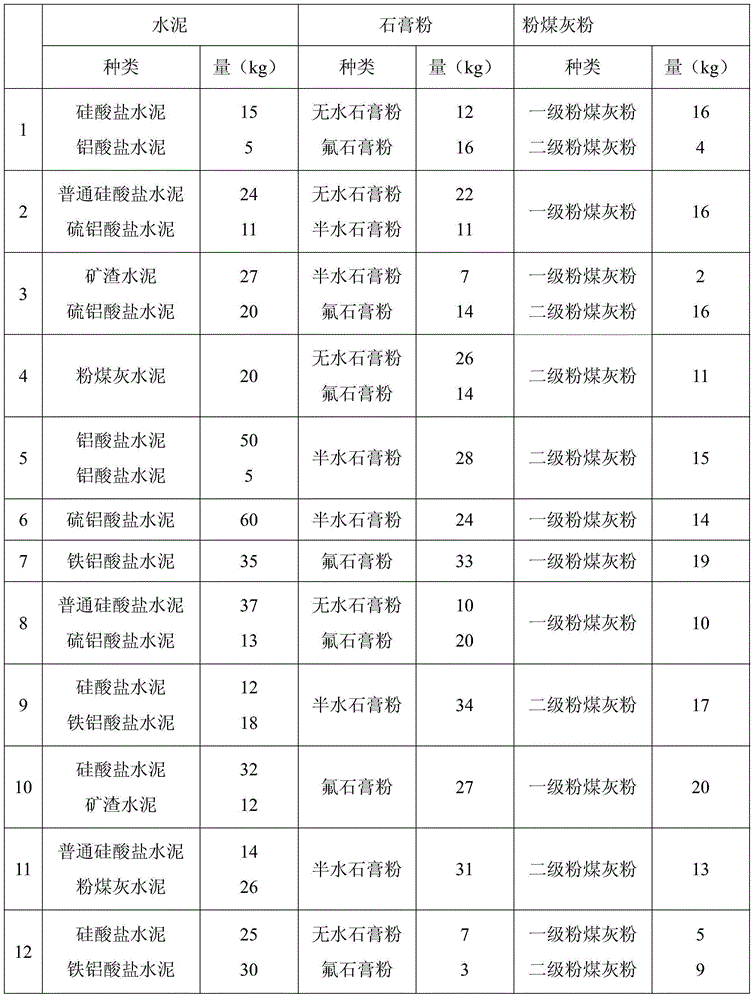

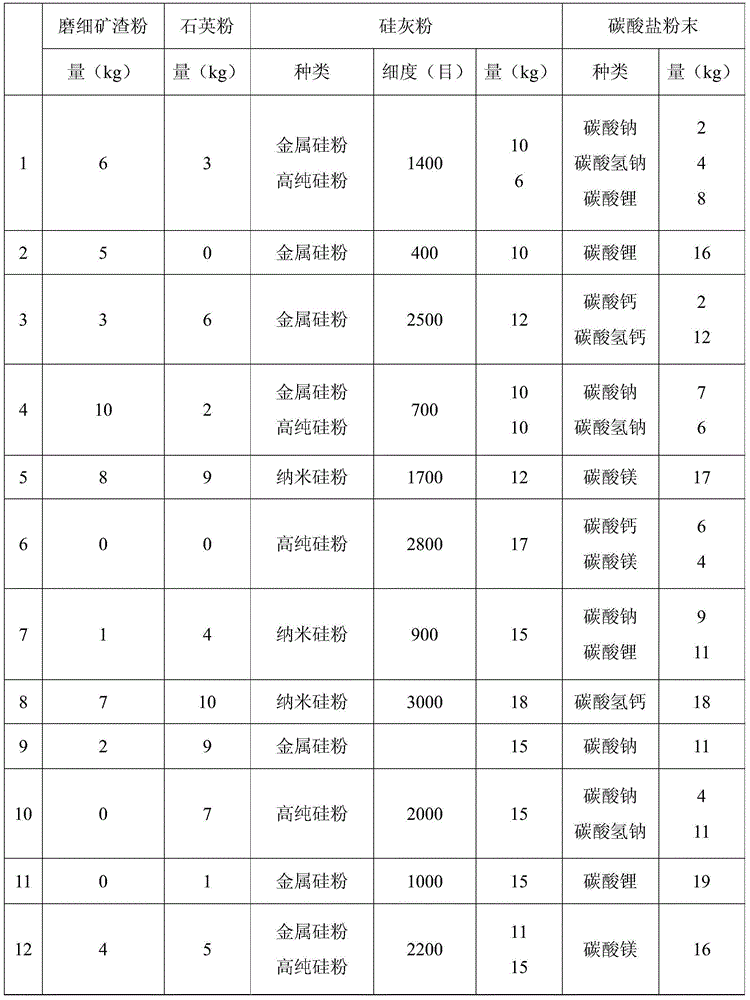

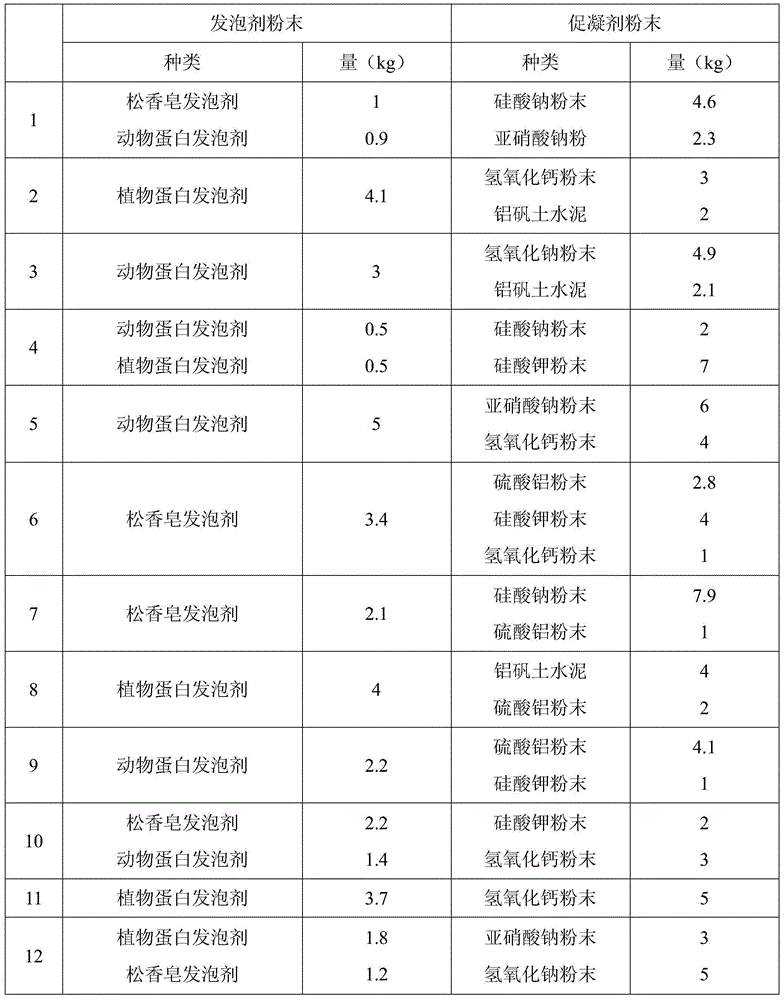

[0028] The hole-filling hydraulic inorganic powder foaming material of this embodiment is prepared according to the raw materials of No. 1-3 in Table 1-3.

[0029] The application of the cavity-filling hydraulic inorganic powder foaming material of this embodiment is used for large-volume filling of downhole caving areas, cavities and racks. It proceeds as follows:

[0030] 1. Add the raw materials into the mixer, stir and mix for 15 minutes, and the dry powder mixture is obtained;

[0031] 2. Mix the dry powder mixture prepared in step 1 with water according to the mass ratio of 1:2, and then use the screw type grouting pump for high-speed stirring and continuous output to form foam slurry, and place the foam slurry through the grouting pipeline Filling in downhole caving areas, cavities and large-volume positions behind racks.

Embodiment 2

[0033] The hole-filling hydraulic inorganic powder foaming material of this embodiment is prepared according to the raw materials of No. 4-6 in Table 1-3.

[0034] The application of the hole-filling hydraulic inorganic powder foaming material of this embodiment is used for fast filling of the upper and lower corners, and is carried out according to the following steps:

[0035] 1. Add the raw materials into the mixer, stir and mix for 15 minutes, and the dry powder mixture is obtained;

[0036] 2. Mix the dry powder mixture prepared in step 1 with water according to the mass ratio of 1:2.5, stir and output continuously through the screw type grouting pump at high speed, and make foam slurry at the mouth of the transportation pipeline, and inject the foam slurry into the upper and lower corners Filling can be completed within the pre-made frame.

Embodiment 3

[0038] The hole-filling hydraulic inorganic powder foaming material of this embodiment is prepared according to the raw materials of No. 7-9 in Table 1-3.

[0039] The application of the hole-filling hydraulic inorganic powder foaming material of this embodiment, which is used for filling and sealing coal mine fires or high-temperature areas, is carried out according to the following steps:

[0040] 1. Add the raw materials into the mixer, stir and mix for 15 minutes, and the dry powder mixture is obtained;

[0041] 2. Mix the dry powder mixture prepared in step 1 with water according to the mass ratio of 1:3, and then use the screw type grouting pump for high-speed stirring and continuous output to form foam slurry, and inject the foam slurry through the grouting pipeline Go to the underground fire area or high temperature area for filling and sealing and fire prevention and extinguishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com