Chromatographic separation method of trehalose and maltose

A chromatographic separation and trehalose technology, applied in the field of biochemical separation, can solve the problems of difficult construction of special chromatographic media, high energy consumption, high equipment requirements, etc., and achieve the effect of low cost, high product purity and high separation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

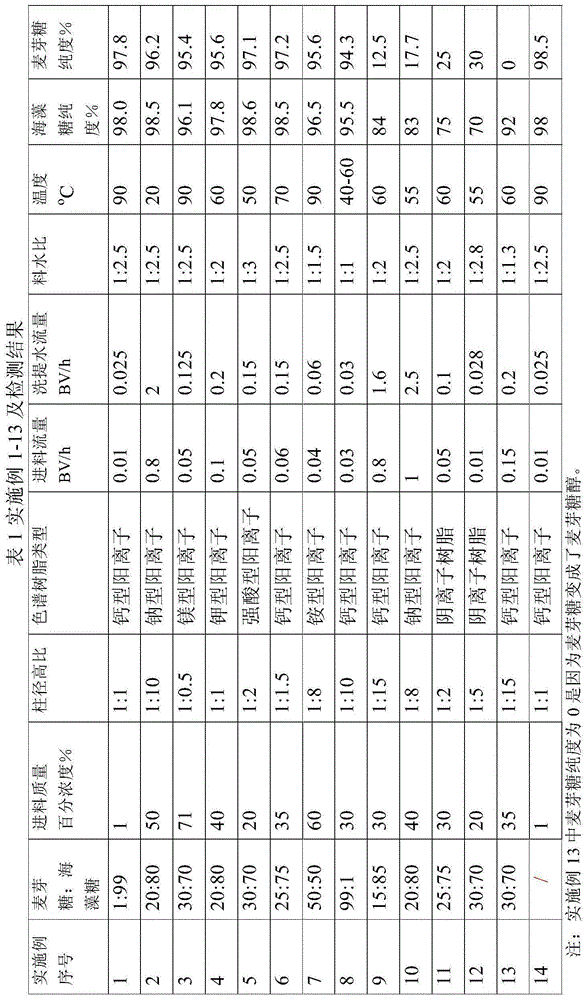

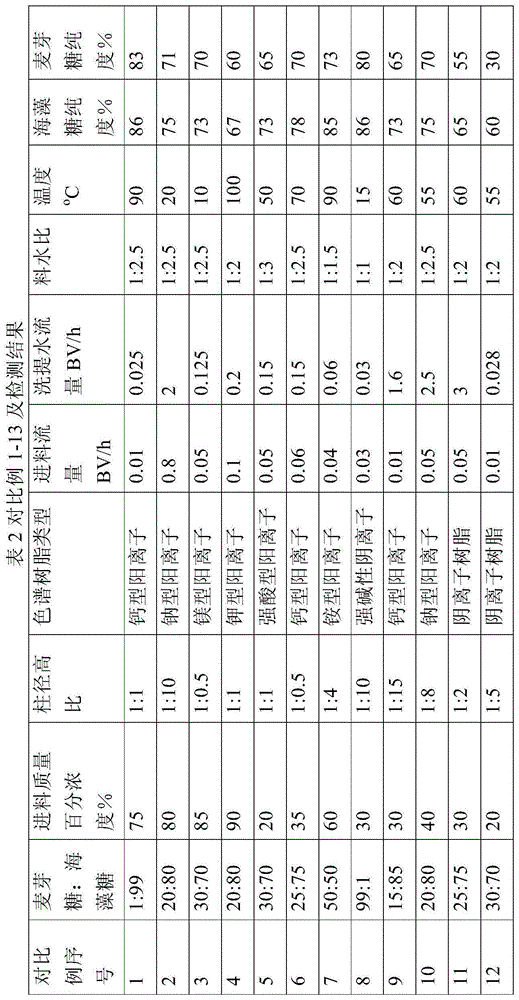

Examples

Embodiment 1

[0034] The feed aqueous solution of maltose and trehalose (mass percentage 1% maltose, 99% trehalose) (the mass percentage concentration of the total content of maltose and trehalose is 1%), and the injection diameter-to-height ratio is 1:1 to fill calcium-type cations Chromatographic resin chromatographic column, the column temperature is controlled at 90°C, the feed flow rate is 0.01BV / h; deionized water is used as the eluent, the ratio of material to water is 1:2.5, and the column temperature is controlled at 90°C (the column temperature is controlled during the whole separation process keep constant) and the flow rate is 0.025BV / h; the eluate and residual liquid are collected respectively to obtain aqueous solutions of maltose and trehalose, and the separation rate of the two substances is 98.0%.

[0035] The calculation method of the above separation rate is:

[0036] Separation rate: K=(H-h) / H×100%, K—separation rate of peak height, H—peak height of small peak, h—height ...

Embodiment 14

[0041] Filter the trehalose material liquid produced by maltase conversion through membrane filtration (the filtration conditions of membrane filtration are: microfiltration membrane (CA membrane), temperature: 25-30°C, operating pressure: 0.01-0.2MPa), and concentrate through the membrane (Membrane concentration conditions are: nanofiltration membrane (NF-1-D-4040), temperature 25-30°C, pressure 0.5-1MPa) to make an aqueous solution with a concentration of 1% (w / w), and the injection diameter-to-height ratio is 1: 1 Fill a calcium-type cation chromatography resin column, control the column temperature at 90°C, and feed the flow rate at 0.01BV / h; use deionized water as the eluent, the ratio of material to water is 1:2.5, and control the column temperature at 90°C (column Temperature remains constant throughout the separation process) and the flow rate is 0.025BV / h conditions for eluting; respectively collect the eluate and residual liquid to obtain the aqueous solutions of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com