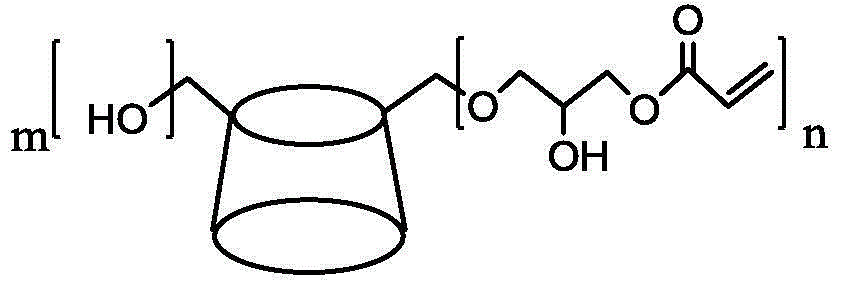

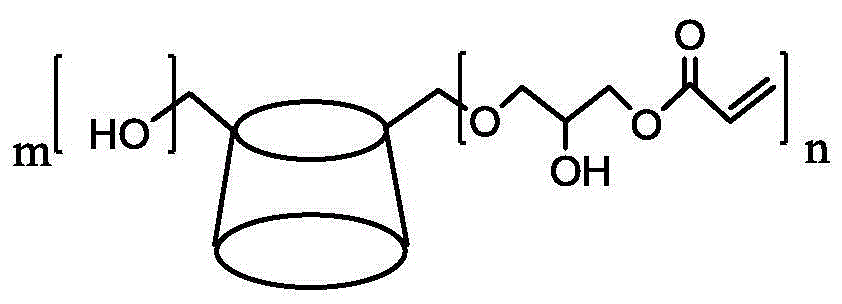

Epoxy acrylate based on cyclodextrin and preparing method thereof

A technology of epoxy acrylate and cyclodextrin, applied in cyclodextrin coatings and other directions, can solve the problems of high toxic skin irritation and low viscosity, and achieve the effects of low preparation cost, simple operation and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

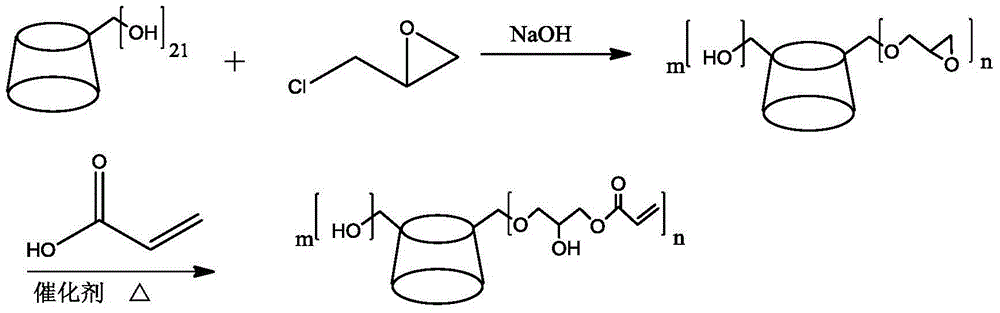

Method used

Image

Examples

Embodiment 1

[0022] The first step reaction: mix 0.1mol cyclodextrin, 2mol epichlorohydrin and 0.3% mol tetrabutylammonium bromide of the reaction system, and add it to a condensing tube, a thermometer, a stirring rod and a constant pressure dropping funnel In a 250ml four-neck flask, the temperature was raised to 58°C with stirring, and NaOH solution (45wt%, 49g) was started to be added dropwise, and the drop rate was controlled at 2 drops / min, and the drop was completed in about 2 hours. After the dropwise addition, continue to stir for 4 hours to measure the epoxy value. When it reaches the maximum value, the reaction is terminated and cooled to room temperature. Post-processing: filter with suction to remove the NaCl crystals produced by the reaction, wash the organic phase twice with deionized water, and then dry it overnight with anhydrous sodium sulfate. Distill under reduced pressure to remove excess unreacted epichlorohydrin in the product.

[0023] The second step of reaction: t...

Embodiment 2

[0025] The first step reaction: mix 0.1mol cyclodextrin, 2.5mol epichlorohydrin and 0.3% mol tetramethylammonium chloride of the reaction system, and add to the In a 250ml four-necked flask with a funnel, stir and heat up to 58°C, start to add NaOH solution (45wt%, 49g) dropwise, the drop rate is controlled at 2 drops / min, and the drop is completed in about 2 hours. After the dropwise addition, continue to stir for 4 hours to measure the epoxy value. When it reaches the maximum value, the reaction is terminated and cooled to room temperature. Post-processing: filter with suction to remove the NaCl crystals produced by the reaction, wash the organic phase twice with deionized water, and then dry it overnight with anhydrous sodium sulfate. Distill under reduced pressure to remove excess unreacted epichlorohydrin in the product.

[0026] The second step reaction: take 0.05mol of the first step reaction product, add 2.5mol of acrylic acid to a three-necked flask, then add 1wt% hy...

Embodiment 3

[0028]The first step reaction: mix 0.1mol cyclodextrin, 3mol epichlorohydrin and 0.3% mol tetraethylammonium bromide of the reaction system, and add it to a condensing tube, a thermometer, a stirring rod and a constant pressure dropping funnel In a 250ml four-necked flask, stir and heat up to 58°C, start to add NaOH solution (45wt%, 98g) dropwise, the drop rate is controlled at 2 drops / min, and the drop is completed in about 2 hours. After the dropwise addition, continue to stir for 4 hours to measure the epoxy value. When it reaches the maximum value, the reaction is terminated and cooled to room temperature. Post-processing: filter with suction to remove the NaCl crystals produced by the reaction, wash the organic phase twice with deionized water, and then dry it overnight with anhydrous sodium sulfate. Distill under reduced pressure to remove excess unreacted epichlorohydrin in the product.

[0029] Second-step reaction: get 0.05mol of the first-step reaction product, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com