Ultrafine-grinding assisted enzymatic-hydrolysis based preparation method of wheat bran oligosaccharides

A technology of ultrafine grinding and wheat bran, which is applied in the field of food processing, can solve the problems of environmental pollution, high yield of oligosaccharides, and many side reactions, and achieve the goals of reducing environmental pollution, improving enzymatic hydrolysis efficiency, and improving utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

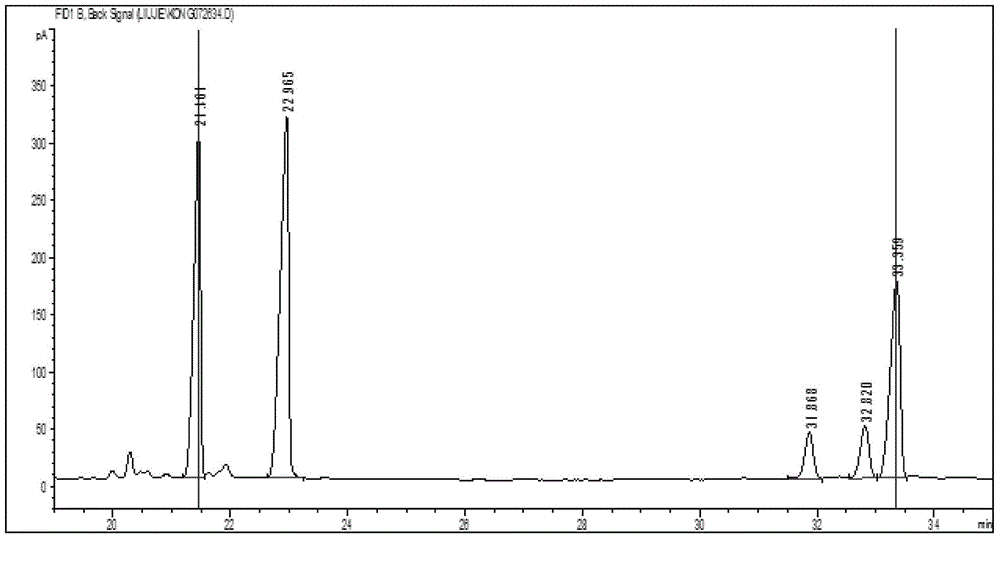

Image

Examples

Embodiment 1

[0034] A method for preparing wheat bran oligosaccharides by an ultrafine pulverization assisted enzymatic method, the specific steps are as follows:

[0035] (1) Superfine pulverization: the wheat bran of common pulverization is the wheat bran powder that particle size is less than 100 microns through superfine pulverization;

[0036] (2) Composite enzymatic hydrolysis to prepare oligosaccharides: mix ultra-finely pulverized wheat bran powder with water at a mass ratio of 1:8 to obtain wheat bran slurry; use high temperature resistant α-amylase and glucoamylase to degrade the wheat bran slurry Starch (high temperature resistant α-amylase enzymolysis conditions: pH 5.0, temperature 90°C, enzyme addition 100U / g, time 10min; glucoamylase enzymolysis conditions: pH 4, temperature 60°C, enzyme addition 80U / g, time 20min); use alkaline protease to degrade protein (enzymolysis conditions: pH 7, temperature 50°C, enzyme addition amount 0.015AU / g, time 10min); use cellulase and xylana...

Embodiment 2

[0039] A method for preparing wheat bran oligosaccharides by an ultrafine pulverization assisted enzymatic method, the specific steps are as follows:

[0040] (1) Superfine pulverization: the wheat bran of common pulverization is the wheat bran powder that particle size is less than 100 microns through superfine pulverization;

[0041] (2) Composite enzymatic hydrolysis to prepare oligosaccharides: mix ultra-finely pulverized wheat bran powder with water at a mass ratio of 1:20 to obtain wheat bran slurry; use high temperature resistant α-amylase and glucoamylase to degrade the wheat bran slurry Starch (high temperature resistant α-amylase enzymolysis conditions: pH 7.0, temperature 100°C, enzyme addition 110U / g, time 30min; glucoamylase enzymolysis conditions: pH 6, temperature 70°C, enzyme addition 90U / g, time 30min); use alkaline protease to degrade protein (enzymolysis conditions: pH 8, temperature 70°C, enzyme addition 0.02AU / g, time 30min); use cellulase and xylanase to pr...

Embodiment 3

[0044] A method for preparing wheat bran oligosaccharides by an ultrafine pulverization assisted enzymatic method, the specific steps are as follows:

[0045] (1) Superfine pulverization: the wheat bran of common pulverization is the wheat bran powder that particle size is less than 100 microns through superfine pulverization;

[0046] (2) Composite enzymatic hydrolysis to prepare oligosaccharides: mix ultra-finely pulverized wheat bran powder and water at a mass ratio of 1:12 to obtain wheat bran slurry; use high-temperature-resistant α-amylase and glucoamylase to degrade the wheat bran slurry Starch (high temperature resistant α-amylase enzymolysis conditions: pH 6.0, temperature 95°C, enzyme addition 110U / g, time 10min; glucoamylase enzymolysis conditions: pH 5, temperature 60°C, enzyme addition 90U / g, time 20min); use alkaline protease to degrade protein (enzymolysis conditions: pH 7, temperature 60°C, add enzyme amount 0.02AU / g, time 10min); use cellulase and xylanase to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com