Preparation method of carboxylation hydrothermal biomass charcoal for remedying uranium-containing wastewater

A biomass carbon, carboxylation technology, applied in chemical instruments and methods, water/sewage treatment, adsorbed water/sewage treatment, etc. Reduce the number of problems, to achieve the effect of large adsorption capacity, high carboxyl content and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Dry the pine needles at 80°C and crush them to 40 meshes. Weigh 10g of pine needle powder, 0.2g of citric acid and 60ml of distilled water into a 100ml hydrothermal reaction kettle, react at 180°C for 16h, and then filter to obtain hydrothermal biochar. Then, 10g of hydrothermal biochar was added to 100ml of 2mol / L HNO 3 In the solution, react at 80°C for 1 hour, then filter, wash and dry to obtain carboxylated hydrothermal biomass charcoal HTC-COOH-1.

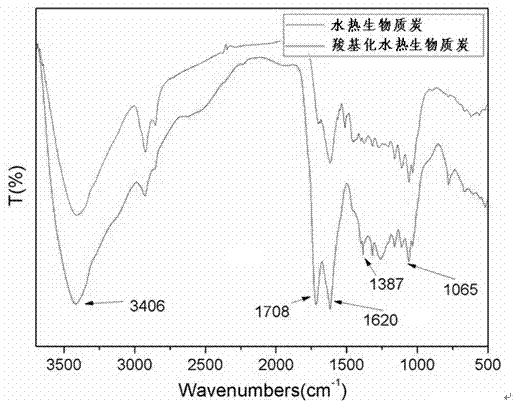

[0021] figure 1 is the infrared spectrum of hydrothermal biochar and carboxylated hydrothermal biochar, in which, 1708 cm -1 It is the stretching vibration peak of C=O in the carboxyl group, 3400cm -1 is the stretching vibration peak of -OH. The results showed that the carboxyl content on the surface of hydrothermal biochar increased significantly after carboxylation.

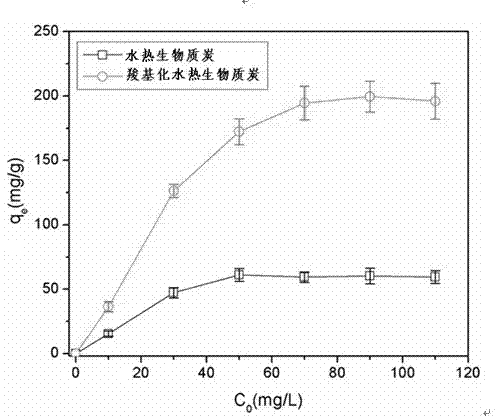

[0022] figure 2 is the effect of initial concentration on the uranium adsorption capacity of hydrothermal biochar and carboxylated hydrothermal bi...

Embodiment 2

[0025] Dry the orange peel at 80°C and crush it to 20 meshes. Weigh 10g of orange peel powder, 0.1g of phosphoric acid and 60ml of distilled water into a 100ml hydrothermal reaction kettle, react at 200°C for 6 hours, and then filter to obtain hydrothermal biochar. Then, 10g of hydrothermal biochar was added to 100ml of 1.5mol / L KMnO 4 In the solution, react at 70°C for 2 hours, then filter, wash and dry to obtain carboxylated hydrothermal biomass charcoal HTC-COOH-2.

Embodiment 3

[0027] Dry the rice straw at 80°C and crush it to 20 meshes. Weigh 10g of straw powder, 0.3g of formic acid and 60ml of distilled water into a 100ml hydrothermal reactor, react at 180°C for 8 hours, and then filter to obtain hydrothermal biochar. Then, 10 g of hydrothermal biochar was added to 100 ml of 1.0 mol / L sodium persulfate sulfuric acid solution, reacted at 80 °C for 4 hours, filtered, washed and dried to obtain carboxylated hydrothermal biochar HTC-COOH-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com