Hollow bimetal nanoparticle/titanium dioxide core-shell structure, and preparation method and application thereof

A technology of metal nanoparticles and bimetallic nanometers, which is applied in the application field of photocatalytic degradation of organic matter, can solve the problems of easy aggregation of bimetallic nanoparticles and small contact area between bimetallic nanoparticles and titanium dioxide, and achieve better catalytic effect and conditions Mild, good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

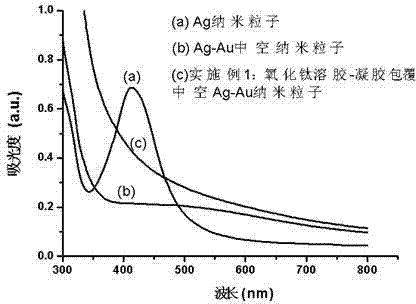

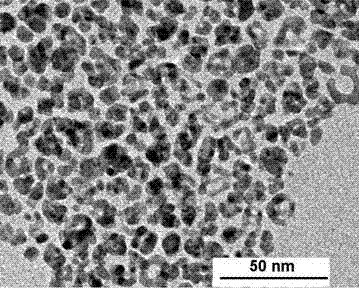

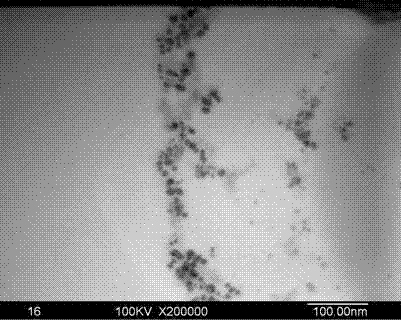

[0052] (1) Preparation steps of hollow bimetallic nanoparticles: Weigh 0.5g of polyvinylpyridine-polyethylene oxide block copolymer (PVP-b-PEO), add 0.12g of silver nitrate (where Ag / VP=0.6), add Solvent tetrahydrofuran was used to prepare a solution with a concentration of 0.05 wt% of the block copolymer, and stirred for 2 days to obtain a clear and transparent solution. On this basis, a certain amount of ultraviolet absorber 2,4-dihydroxybenzophenone (BPH) was added. Transfer the solution into a quartz bottle and irradiate it with ultraviolet light (254nm) for 10-20 hours to obtain a yellow silver nanoparticle solution; weigh 40g of the prepared silver nanoparticle solution, and add 1mg / mL HAuCl under stirring 4 190 microliters of the THF solution of THF were subjected to displacement reaction for at least 24 h to obtain hollow gold-silver bimetallic nanoparticles containing block copolymers on the surface, wherein the molar ratio of Au to Ag was 0.5. figure 1 (a) and (b) are t...

Embodiment 2

[0057] (1) Weigh 100 mg of PVP-b-PEO block copolymer (ie, polyvinylpyridine-polyethylene oxide block copolymer), add 24.0 mg of silver nitrate and 10 g of solvent tetrahydrofuran, stir for at least 1 day to form a colorless and transparent To the solution, add 20 mg of BPH (2,4-dihydroxybenzophenone), and irradiate the above solution with ultraviolet rays with a wavelength of 254 nm for 16 hours to obtain a yellow Ag nanoparticle solution. The surface of the Ag nanoparticle contains block copolymer .

[0058] (2) Take 400 mg of the prepared silver nanoparticle solution and add HAuCl 4 The solution (1mg / ml) was 18 μl, and the displacement reaction was carried out for at least 24 hours to obtain hollow bimetallic Ag-Au (wherein the molar ratio of Au to Ag was 0.39) nanoparticles containing block copolymers on the surface.

[0059] (3) The hollow bimetallic nanoparticles containing the block copolymer prepared above were further diluted to a concentration of 0.05wt%, and then a titani...

Embodiment 3

[0062] Weigh 100 mg of PVP-b-PEO block copolymer, add 24 mg of silver nitrate and 20 g of solvent tetrahydrofuran, stir for at least 1 day to form a colorless and transparent solution, add 20 mg of BPH, and irradiate the above solution with ultraviolet rays with a wavelength of 254 nm for 16 hours , To obtain a yellow Ag nanoparticle solution. Take 400 mg of the prepared silver nanoparticle solution and add HAuCl 4 Solution (1mg / ml) 24μl, carry out displacement reaction for at least 24h to obtain hollow bimetallic Ag-Au nanoparticles (where the molar ratio of Au to Ag is 1.0). The hollow bimetallic nanoparticles containing block copolymer prepared above were further diluted to a concentration of 0.05wt%, and then added dropwise to the sol formed by TTIP under stirring, wherein the volume ratio of titanium dioxide to block copolymer was 5.0% After the addition, continue to stir for 50 minutes. The hollow bimetallic nanoparticles are evenly coated by the sol-gel of titanium dioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com