A kind of sargassum-based activated carbon and its preparation method and application

A technology of sargassum and activated carbon, applied in separation methods, chemical instruments and methods, inorganic chemistry, etc., to achieve the effect of simple processing method, low price, and convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

[0035] Example 1AC (0.5:1-ZnCl 2 -CO 2 -500℃-1h):

[0036] Raw material Sargassum and ZnCl 2Add the chemical activator into a beaker containing 15mL of aqueous solution in a mass ratio of 1:1, and vibrate ultrasonically for 1 hour to make it evenly mixed; place it in a vacuum drying oven after immersing at 105°C for 12 hours after ultrasonic vibration; then use a crucible Place the impregnated mixture in a quartz tube furnace, and raise the temperature from room temperature to 500°C at a rate of 10°C / min under the protection of nitrogen; 2 gas, and stay at this temperature for 1 hour; after naturally cooling to room temperature, wash with 1mol / L HCl solution for several times and then rinse with distilled water until the filtrate is neutral; finally in a vacuum oven at 110°C Drying for 1 hour to obtain sargassum-based activated carbon.

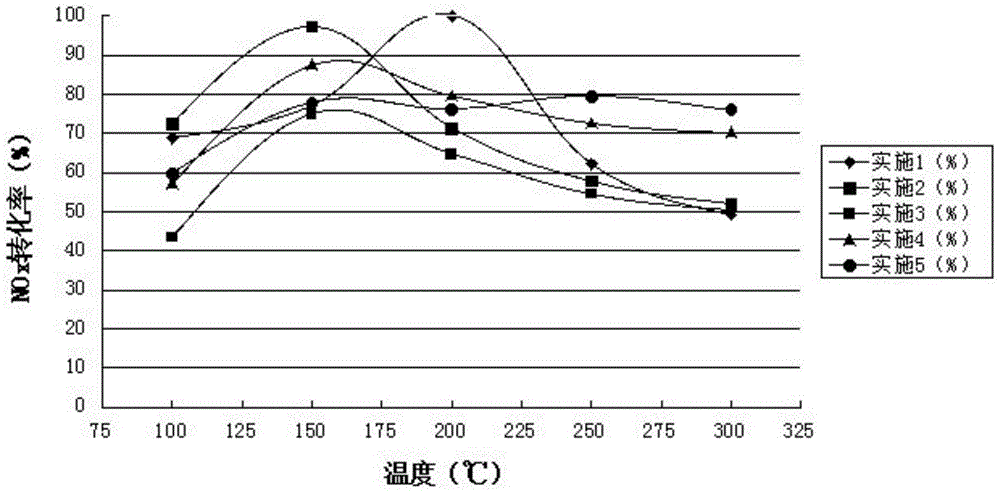

[0037] The sargassum-based activated carbon prepared by this example is tested for its selective catalytic reduction ability to nitrogen ...

Embodiment 2A

[0039] Example 2AC (1:1-ZnCl 2 -CO 2 -500℃-1h):

[0040] Raw material Sargassum and ZnCl 2 Add the chemical activator into a beaker containing 15mL of aqueous solution in a mass ratio of 1:1, and vibrate ultrasonically for 1 hour to make it evenly mixed; place it in a vacuum drying oven after immersing at 105°C for 12 hours after ultrasonic vibration; then use a crucible Place the impregnated mixture in a quartz tube furnace, and raise the temperature from room temperature to 500°C at a rate of 10°C / min under the protection of nitrogen; 2 gas, and stay at this temperature for 1 hour; after naturally cooling to room temperature, wash with 1mol / L HCl solution for several times and then rinse with distilled water until the filtrate is neutral; finally in a vacuum oven at 110°C Drying for 1 hour to obtain sargassum-based activated carbon.

[0041] The sargassum-based activated carbon prepared by this example is tested for its selective catalytic reduction ability to nitrogen o...

Embodiment 3A

[0043] Example 3AC (2:1-H 3 PO 4 -CO 2 -500℃-1h):

[0044] The raw material Sargassum and H 3 PO 4 Add the chemical activator into a beaker containing 15mL of aqueous solution in a mass ratio of 2:1, and vibrate ultrasonically for 1 hour to make it evenly mixed; after ultrasonically vibrating, place it in a vacuum drying oven at 105°C for 12 hours; then use a crucible Place the impregnated mixture in a quartz tube furnace, and raise the temperature from room temperature to 500°C at a rate of 10°C / min under the protection of nitrogen; 2 gas, and stay at this temperature for 1 hour; after naturally cooling to room temperature, wash with 1mol / L HCl solution for several times and then rinse with distilled water until the filtrate is neutral; finally in a vacuum oven at 110°C Drying for 1 hour to obtain sargassum-based activated carbon.

[0045] The sargassum-based activated carbon prepared by this example is tested for its selective catalytic reduction ability to nitrogen ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com