Silica sand tailings and coal gangue-based foamed ceramic and preparation method thereof

A technology of foam ceramics and coal gangue, which is applied in the field of silica sand mine tailings and coal gangue-based foam ceramics and their preparation, can solve problems such as complex preparation processes, achieve good overall performance, reduce maintenance costs, and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

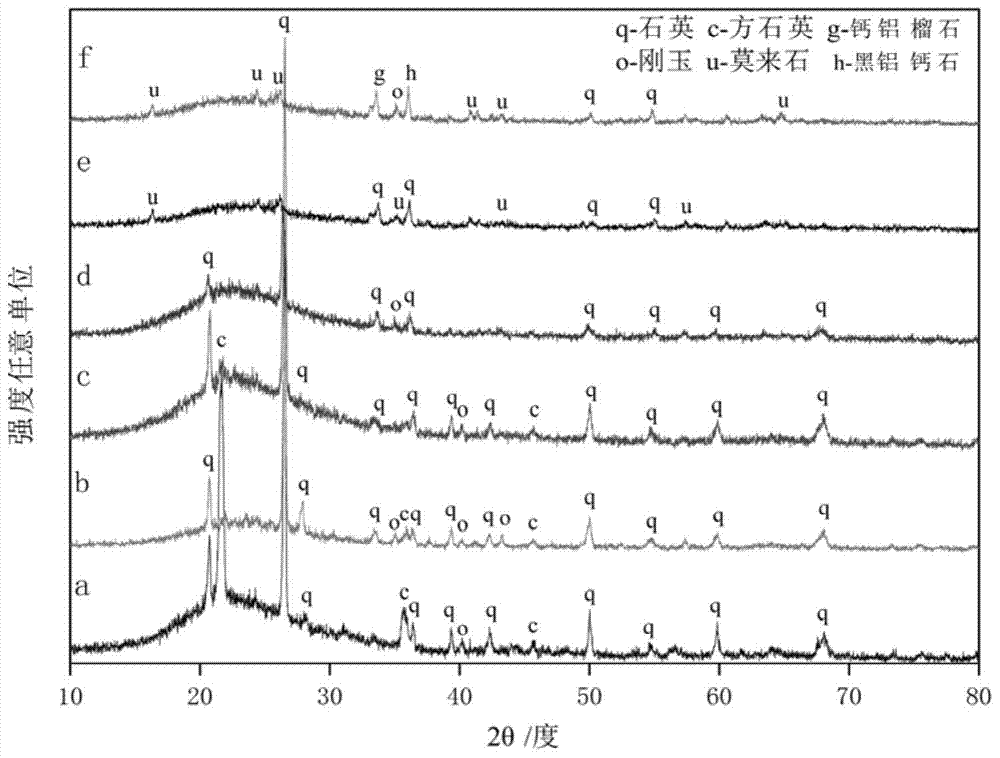

[0037] The raw materials of foam ceramics are mainly composed of 55% of quartz sand (silica sand) mine tailings, 25% of coal gangue, and 20% of sintering aids, of which borax (also known as sodium tetraborate) is 10% in sintering aids, and water glass is 5%. And calcium carbonate is 5% mixture, all are mass percentages.

[0038] Put the raw materials into a ball mill for ball milling, dry and sieve, take 100-300 mesh powder, mix them evenly, put them in a mold and press them for molding, the molding pressure is 10MPa, dry the formed green body, put it into a sintering furnace for sintering , wherein the heating rate is 5°C / min, the sintering temperature is 1100°C, and the temperature is kept for 1 hour.

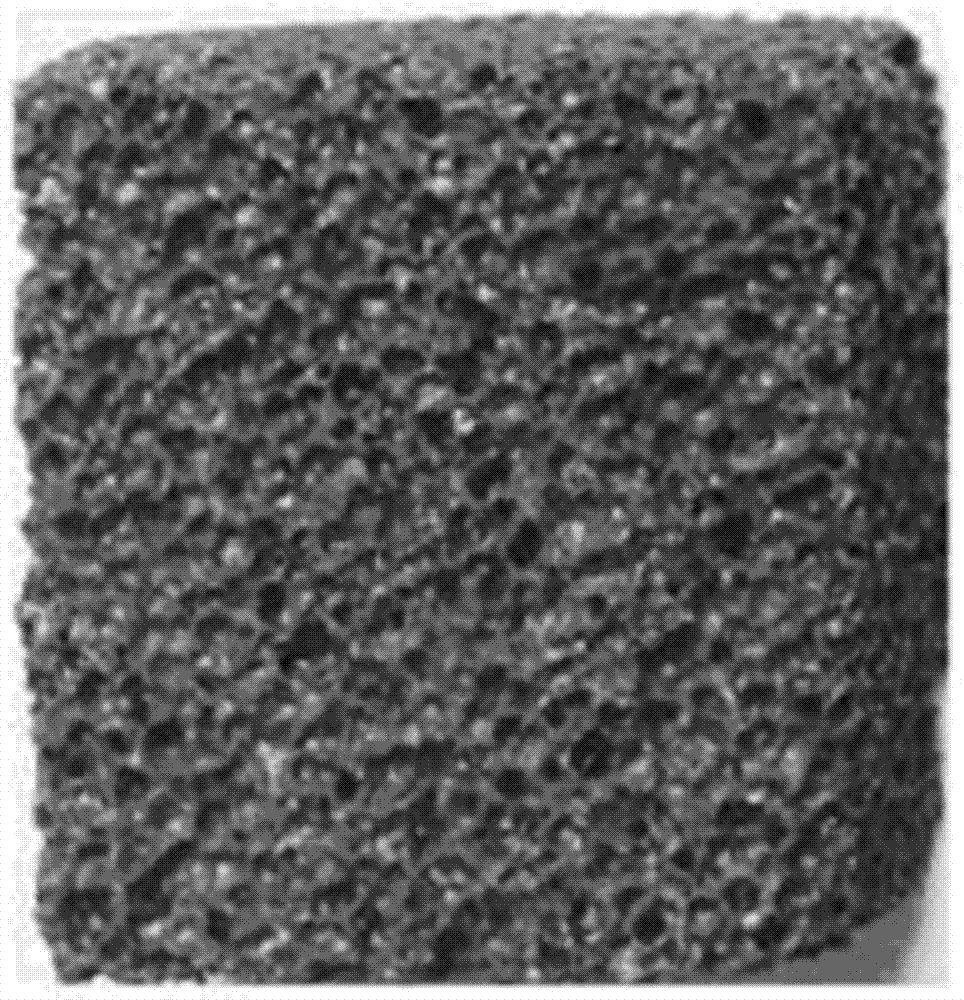

[0039] The porosity of the prepared ceramic foam is 61.6%, and the bulk density is 0.74g / cm 3 , Bending strength 6.2MPa, compressive strength 15.2MPa, acid resistance 98.3%, alkali resistance 99.4%.

Embodiment 2

[0041] The main composition of foam ceramics is: SiO 2 67.5%, Al 2 o 3 17.5%, WO 3 1.35%, Fe 2 o 3 0.65%, Na 2 O 3.5%, B 2 o 3 5%, CaO 5%. SiO 2 50%, Al 2 o 3 35%, WO 3 1%, Fe 2 o 3 1%, Na 2 O 3.5%, B 2 o 3 5%, CaO 4.5%.

[0042] The raw material composition is: 50% of quartz sand (silica sand) mine tailings, 30% of coal gangue, 20% of sintering aids, of which 10% of borax (also known as sodium tetraborate) in sintering aids, 2.5% of water glass and calcium carbonate It is a mixture of 7.5%, both are mass percentages.

[0043] Put the raw materials into a ball mill for ball milling, dry and sieve, take 100-300 mesh powder, mix them evenly, put them in a mold and press them for molding, the molding pressure is 15MPa, fully dry the formed body, and put it into a sintering furnace Sintering, wherein the heating rate is 3°C / min, the sintering temperature is 1120°C, and the temperature is kept for 2 hours.

[0044] The porosity of the prepared ceramic foam is 71...

Embodiment 3

[0046] The main composition of foam ceramics is: SiO 2 61.5%, Al 2 o 3 25%, WO 3 1.25%, Fe 2 o 3 0.75%, Na 2 O 3%, B 2 o 3 4%, CaO 4.5%. SiO 2 50%, Al 2 o 3 35%, WO 3 1%, Fe 2 o 3 1%, Na 2 O 3.5%, B 2 o 3 5%, CaO 4.5%.

[0047] The raw material composition is: 42.5% of quartz sand (silica sand) mine tailings, 42.5% of coal gangue, 15% of sintering aids, of which 5% of borax (also known as sodium tetraborate) in sintering aids, 5% of water glass and calcium carbonate For 5% mixtures, all are percentages by mass.

[0048] Put the raw materials into a ball mill for ball milling, sieve, take 100-300 mesh powder, mix them evenly, put them in a mold and press them for molding, the molding pressure is 10MPa, fully dry the formed body, put it into a sintering furnace for sintering, The heating rate is 5°C / min, the sintering temperature is 1160°C, and the temperature is kept for 4 hours.

[0049] The porosity of the prepared ceramic foam is 68.54%, and the bulk dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| acid resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com