Supramolecular structure phenolphtalein or its analog-inserted UV blocking material and preparation method thereof

A technology of molecular structure and UV blocking, applied in the direction of building insulation materials, building components, building structures, etc., can solve the problems of performance degradation, viscosity increase, softening point increase, etc., to improve the absorption strength and anti-ultraviolet aging ability , The effect of enhanced absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step A: 30.72g (0.12mol) of solid Mg(NO 3 ) 2 ·6H 2 O and 22.51g (0.06mol) of solid Al(NO 3 ) 3 9H 2 O, soluble in removing CO 2 150mL of mixed salt solution was prepared in deionized water; 14.4g of NaOH was weighed and dissolved in 2 Prepare 150mL alkali solution in deionized water; put the two solutions into a rotating membrane reactor at the same flow rate at room temperature to quickly nucleate, transfer the obtained slurry to a 500mL flask, crystallize at 80°C for 8 hours, and centrifuge to wash until The pH is about 7, dried at 60°C for 12 hours to obtain the precursor of nitrate intercalated magnesium aluminum hydrotalcite, whose structural formula is Mg 0.64 al 0.36 (OH) 2 (NO 3 - ) 0.36 0.9H 2 O;

[0025] Get above-mentioned product 22.81g (0.01molNO 3 —) in a three-necked flask with CO removal 2 Ultrasonic dispersion in deionized water, prepared into 75mL suspension;

[0026] Step B: Weigh 6.36g (0.02mol) of phenolphthalein and dissolve it in ...

Embodiment 2

[0032] Step A: Prepare the precursor suspension of nitrate intercalated magnesium aluminum hydrotalcite, the method is the same as step A in Example 1;

[0033] Step B: Weigh 3.18g (0.01mol) of phenolphthalein and dissolve it in 75mL to remove CO 2Add about 0.03g of NaOH to the deionized water under rapid stirring conditions to adjust the pH of the solution to 11;

[0034] Step C: Under the protection of nitrogen, add the solution of step B to the suspension of step A and mix quickly, the molar ratio of nitrate and phenolphthalein in the precursor of nitrate intercalation magnesium aluminum hydrotalcite is 1:1, crystallize at 90 °C for 8 hours, centrifuge, and remove CO 2 Wash with deionized water until the pH is about 7, and dry at 60°C for 12 hours to obtain a supramolecular structure phenolphthalein intercalated UV blocking material, which is denoted as MgAl-PPN-LDHs.

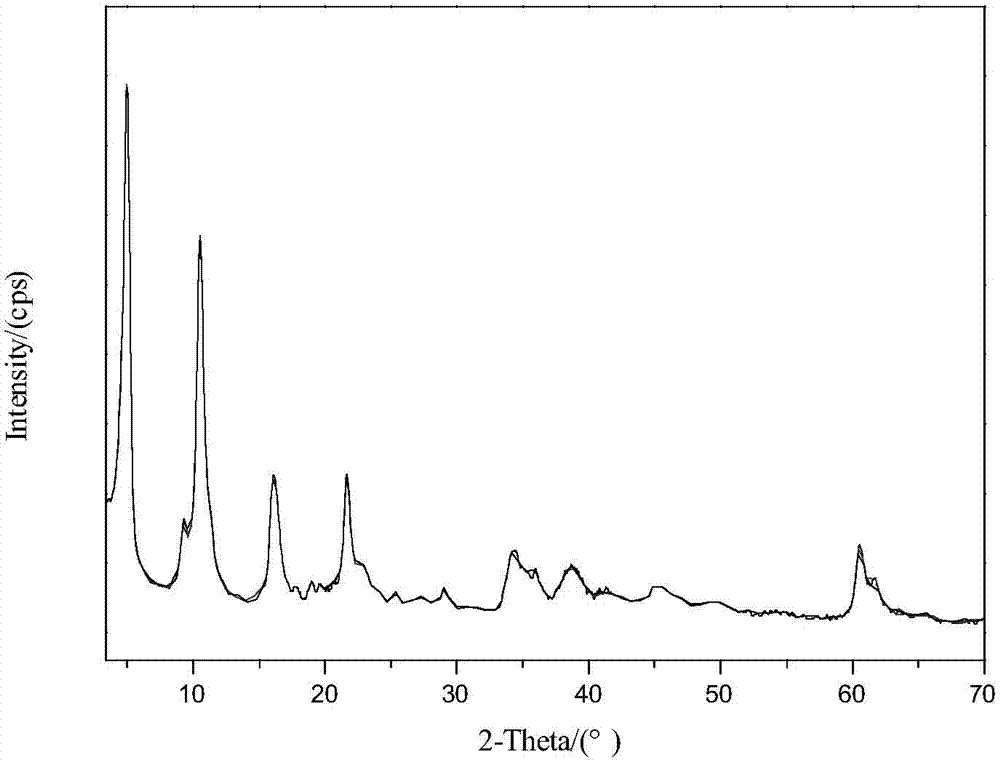

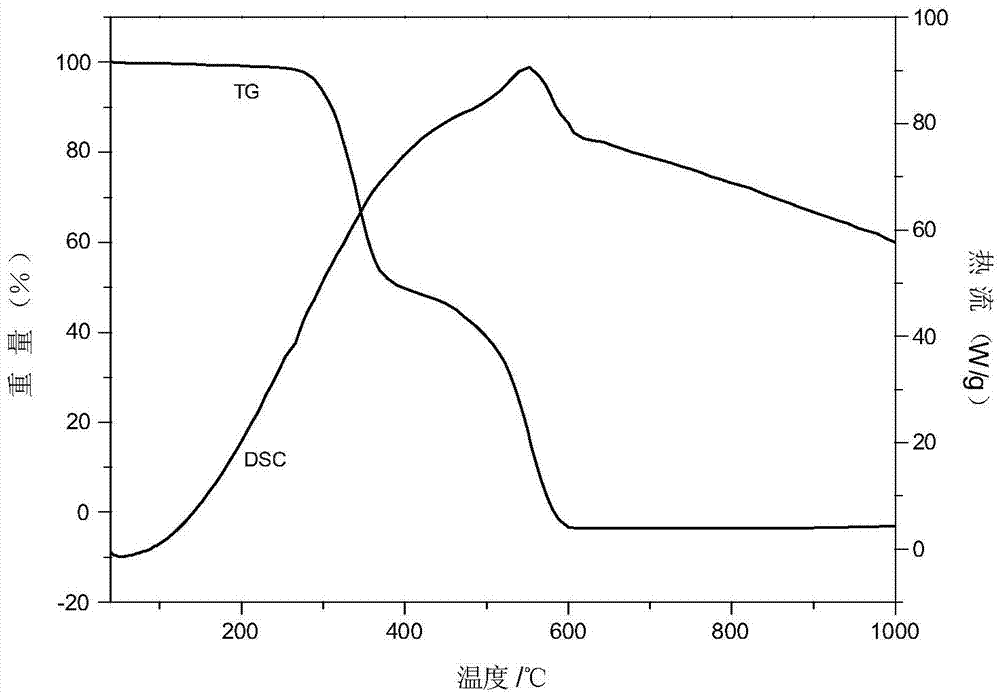

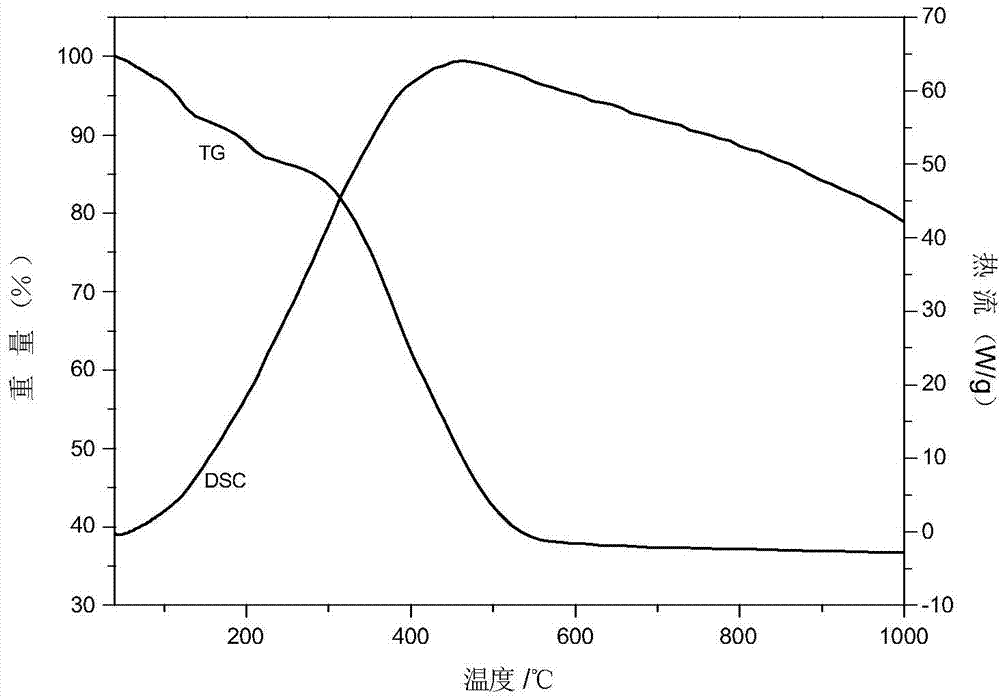

[0035] The obtained product is characterized by XRD, IR, elemental analysis, etc., and its chemical for...

Embodiment 3

[0038] Step A: Prepare the precursor suspension of nitrate intercalated magnesium aluminum hydrotalcite, the method is the same as step A in Example 1;

[0039] Step B: Weigh 12.73g (0.04mol) of phenolphthalein and dissolve it in 75mL to remove CO 2 Add about 0.03g of NaOH to the deionized water under rapid stirring conditions to adjust the pH of the solution to 11.5;

[0040] Step C: Under the protection of nitrogen, add the solution of step B to the suspension of step A and mix quickly. The molar ratio of nitrate and phenolphthalein in the precursor of nitrate intercalated magnesium aluminum hydrotalcite is 1:4, crystallize at 95°C for 6 hours, centrifuge, and remove CO 2 Wash with deionized water until the pH is about 7, and dry at 60°C for 12 hours to obtain a supramolecular structure phenolphthalein intercalated UV blocking material, which is denoted as MgAl-PPN-LDHs.

[0041] The obtained product is characterized by XRD, IR, elemental analysis, etc., and its chemical f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Onset decomposition temperature | aaaaa | aaaaa |

| Onset decomposition temperature | aaaaa | aaaaa |

| Onset decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com