Method for extracting gold and silver from acid making high-iron cinder and removing impurities

A high-speed rail, gold and silver technology, applied in the direction of improving process efficiency, can solve problems such as failure to obtain effective recovery, and achieve the effect of improving the comprehensive recovery value of resources and the grade quality of products, broad application prospects, and promoting sustainable development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

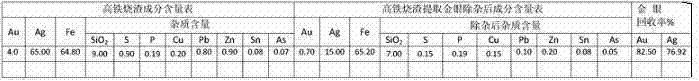

Embodiment 1

[0030] 1) Cyanide gold extraction tailings flotation enrichment of high-sulfur ore:

[0031] Cyanide gold extraction tailings refers to the cyanide tailings produced by the direct cyanide gold extraction process, the main components are: gold 1.0g / t, silver 10g / t, sulfur 20%, iron 15%, lead 0.20%, zinc 0.30%; cyanide tailings are added with water to adjust the slurry to control the pulp concentration to 30%; sodium metabisulfite is used as the activator, the dosage is 100g / t, sulfuric acid is used to adjust the pH value of the pulp to 2, and the dosage of the agent: sodium silicate is used as the gangue inhibitor, the dosage 1000g / t; ethyl xanthate as a collector, the dosage is 500g / t, 2# oil is used as a foaming agent, the dosage is 100g / t; Sulfur concentrate with 48% sulfur grade, 2.0g / t gold grade, 18g / t silver grade, 0.15% copper, 0.30% lead, 0.50% zinc,

[0032] 2) Roasting high-sulfur ore to produce acid produces high-iron slag rich in gold and silver:

[0033] Mix the...

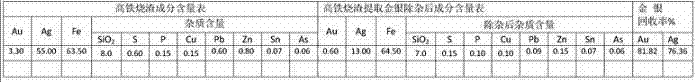

Embodiment 2

[0040] 1) Cyanide gold extraction tailings flotation enrichment of high-sulfur ore:

[0041] Cyanide gold extraction tailings refers to the cyanide tailings produced by the direct cyanide gold extraction process, the main components are: gold 1.5g / t, silver 25g / t, sulfur 25%, iron 20%, lead 0.40%, zinc 0.50%; cyanide tailings are added with water to adjust the slurry to control the pulp concentration to 35%; sodium metabisulfite is used as the activator, the dosage is 500g / t, sulfuric acid is used to adjust the pH value of the pulp to 4, and the dosage of the agent: sodium silicate is used as the gangue inhibitor, the dosage 2000g / t; ethyl xanthate as collector, the dosage is 800g / t, 2# oil is used as foaming agent, the dosage is 200g / t; Sulfur concentrate with a sulfur content grade of 49%, gold grade 3.3g / t, silver grade 45g / t, lead 0.50%, zinc 0.80%;

[0042] 2) Roasting high-sulfur ore to produce acid produces high-iron slag rich in gold and silver:

[0043] The sulfur c...

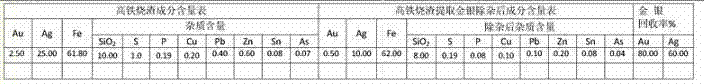

Embodiment 3

[0050] 1) Cyanide gold extraction tailings flotation enrichment of high-sulfur ore:

[0051] Cyanide gold extraction tailings refers to the cyanide tailings produced by the direct cyanide gold extraction process, the main components are: gold 1.3g / t, silver 18g / t, sulfur 23%, iron 17%, lead 0.30%, zinc 0.40%; cyanide tailings are added with water to adjust the slurry to control the pulp concentration to 33%; sodium metabisulfite is used as the activator, the dosage is 300g / t, sulfuric acid is used to adjust the pH value of the pulp to 3, and the dosage of the agent: sodium silicate is used as the gangue inhibitor, the dosage 1500g / t; ethyl xanthate as collector, the dosage is 650g / t, 2# oil is used as foaming agent, the dosage is 150g / t; Sulfur concentrate with a sulfur content grade of 48.50%, gold grade 2.80g / t, silver grade 32.00g / t, lead 0.40%, zinc 0.60%;

[0052] 2) Roasting high-sulfur ore to produce acid produces high-iron slag rich in gold and silver:

[0053] Mix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com