Miniature electrochemical sensor based on direct forming mesoporous carbon technology and manufacturing method

A mesoporous carbon and sensor technology, applied in the direction of electrochemical variables of materials, can solve problems such as application limitations, achieve complete functional structure, achieve performance, and achieve the effect of batch design and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

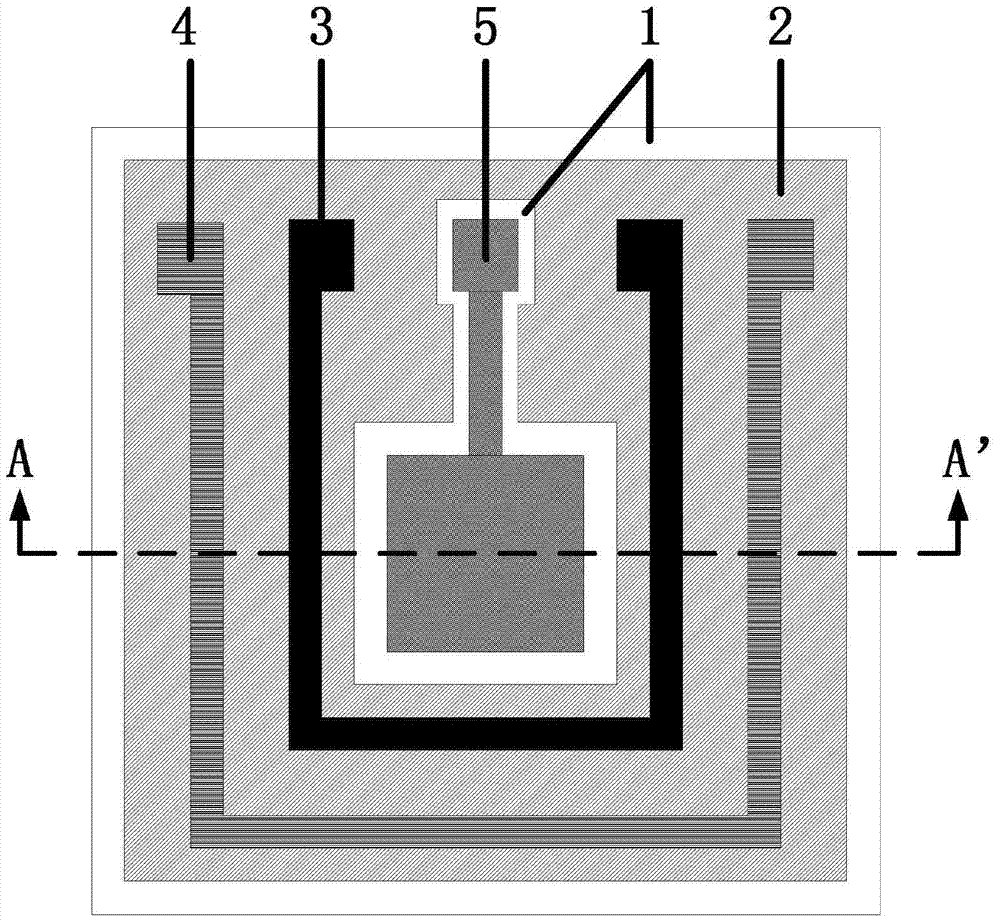

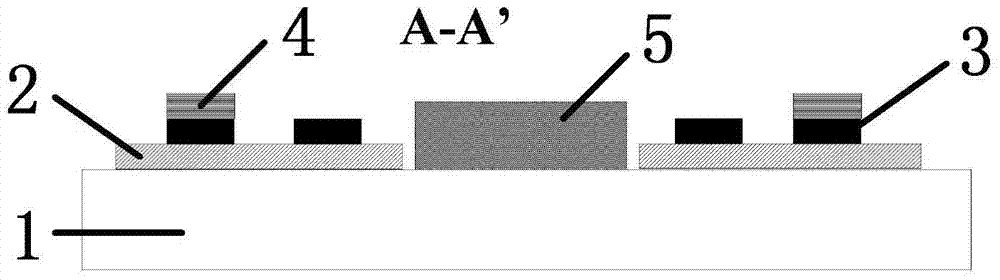

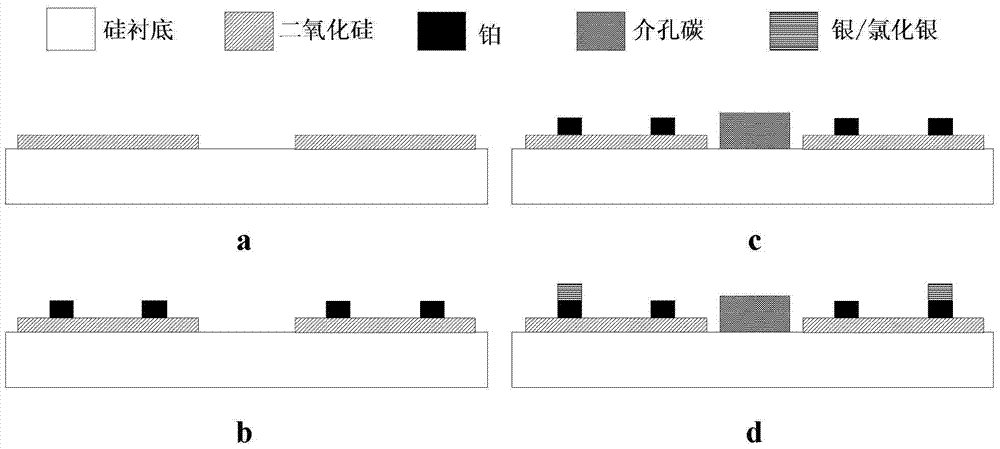

[0022] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings.

[0023] A miniaturized electrochemical sensor based on direct-molded mesoporous carbon technology, such as Figure 1a and Figure 1b As shown, it includes: a device substrate 1, an insulating layer 2, a counter electrode 3 of platinum, a reference electrode 4 of solid silver / silver chloride, and a working electrode 5 of mesoporous carbon; wherein, the device substrate 1 is rectangular, and its The middle is covered with a rectangular working electrode 5 of mesoporous carbon and an electrode lead extending from a certain side of the working electrode 5 of mesoporous carbon; on the device substrate 1, except for the working electrode 5 and the lead of mesoporous carbon, All cover the insulating layer 2, and keep a gap between the insulating layer 2 and the working electrode 5 of the mesoporous carbon and the electrode lead; Small and large U-shaped platinum counter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com