Device and method for monitoring dislocation of loaded wafer of flat plate type epitaxial furnace

A monitoring device and epitaxial furnace technology, which are applied in the fields of semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc. Timely discovery of electrical parameter problems and other problems to avoid serious losses to manufacturers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment applies the chip dislocation (out of pocket) monitoring device of the present invention in the ASM monolithic epitaxy furnace commonly used in the industry at present, and a reaction chamber of the ASM monolithic epitaxy furnace has only one carrier slot, and the present embodiment is used The loading sheet is a single-sided polished silicon wafer. Such as Figure 3aAs shown: a laser transmitter 5 is installed on one side of the outside of the quartz cover 4 in the reaction chamber of the epitaxial furnace, and a laser receiver 6 is installed on the other side outside the quartz cover, which is used for laser detection in out of pocket monitoring Transmitting and receiving; the laser transmitter 5 and the laser receiver 6 are respectively connected to the laser detection & control substrate 7, and the laser detection & control substrate 7 is used as the signal transmission, reception and processing between the laser transmitter 5 and the laser receiver 6...

Embodiment 2

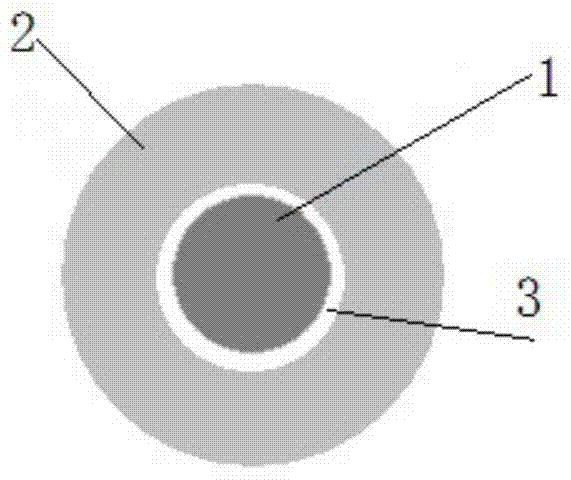

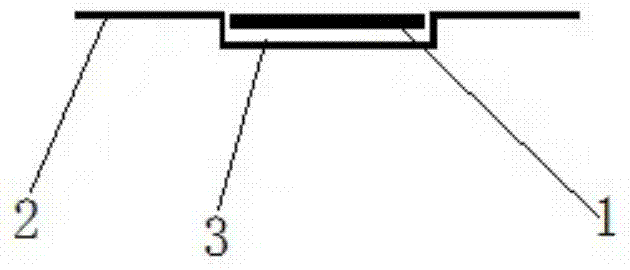

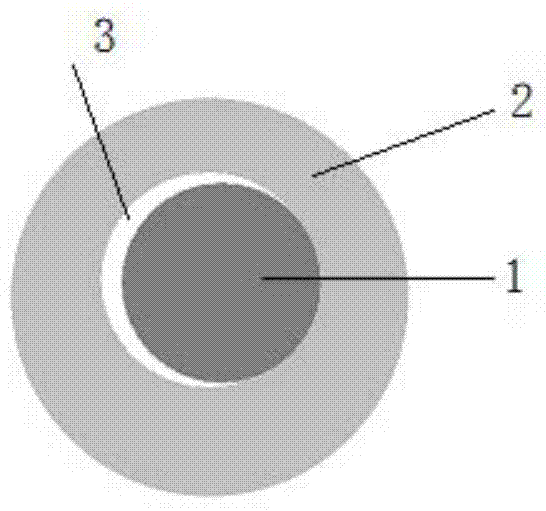

[0042] In this embodiment, the out of pocket monitoring device of the present invention is applied to the LPE3061 epitaxial furnace widely used in the current flat-plate epitaxial furnace. A generation of discrete device technology, IGBT, PowerMos and thin layers, buried layers, and because it is heated by a low-frequency power generator, it can save electricity. The quality of epitaxial wafers is close to that of single-chip furnace products, and the cost is close to that of high-capacity epitaxial furnaces. It is the only epitaxial reaction furnace that can deposit epitaxial films with a thickness of more than 200 microns, so it is currently a common equipment for silicon epitaxial wafer manufacturers. The base of LPE3061 has multiple loading slots 3, which can produce multiple epitaxial wafers at the same time. When loading the wafers, the manipulator 8 automatically loads the loaded wafers in such Figure 5 As shown in the slide slot 3 of the slide loading position corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com