Environmentally friendly and high efficiency solid fuel production method using high-water-content organic waste, and combined heat and power system using same

A technology of organic waste and solid fuel, applied in the direction of solid fuel, waste fuel, biofuel, etc., can solve the problems of fuel odor, etc., and achieve the effect of improving efficiency and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

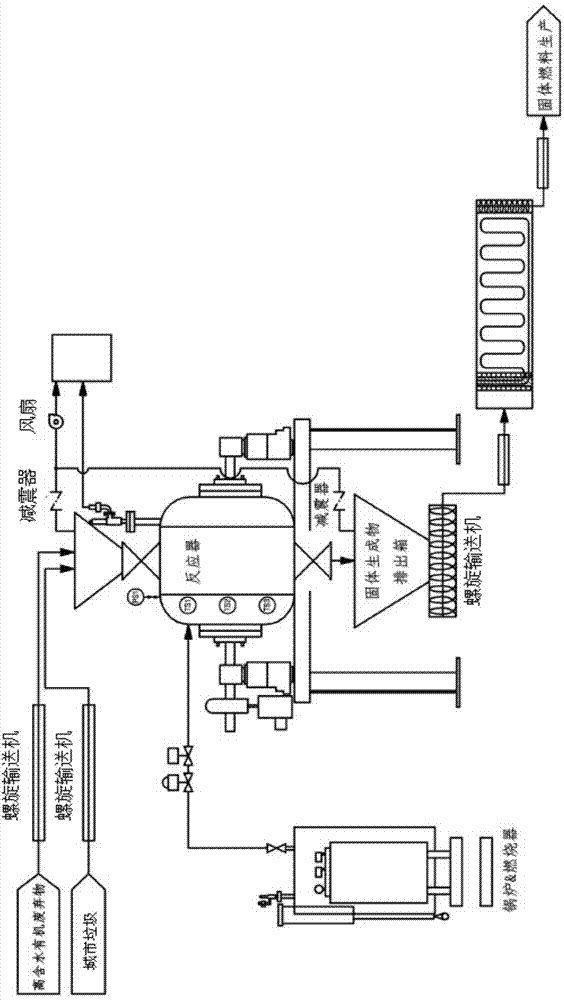

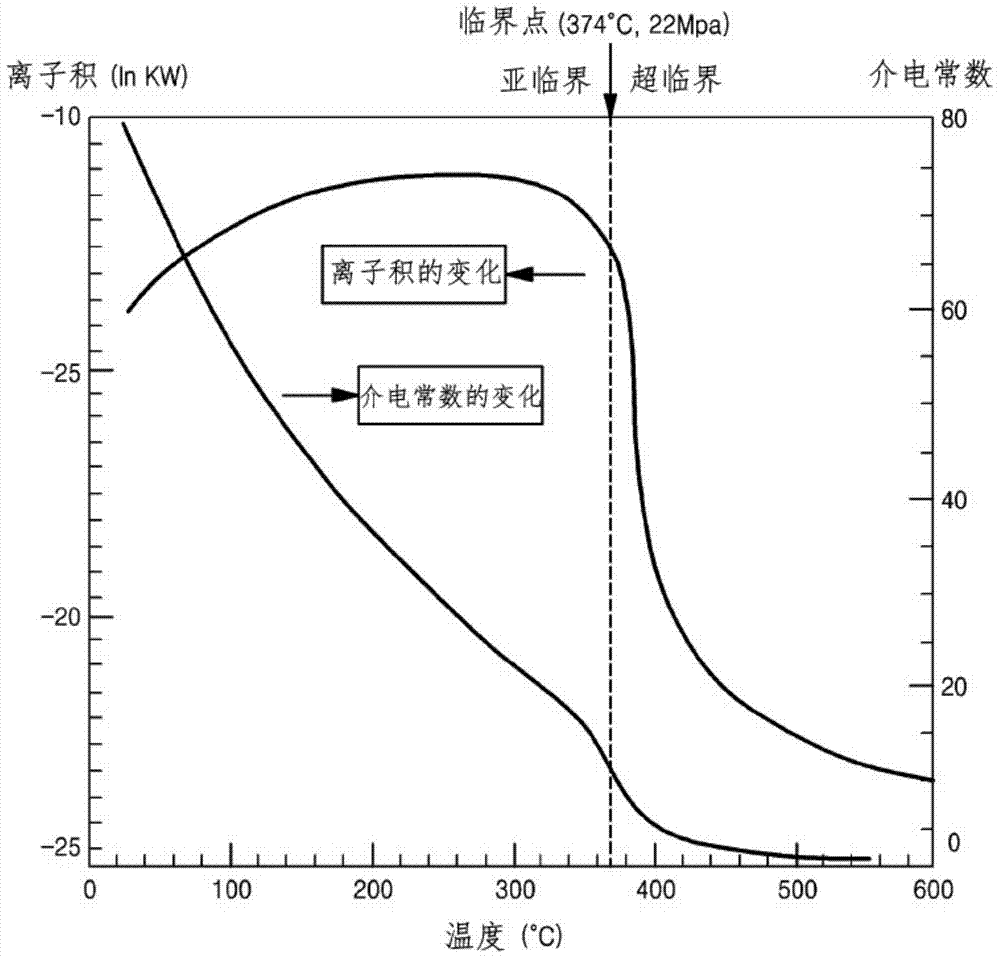

Method used

Image

Examples

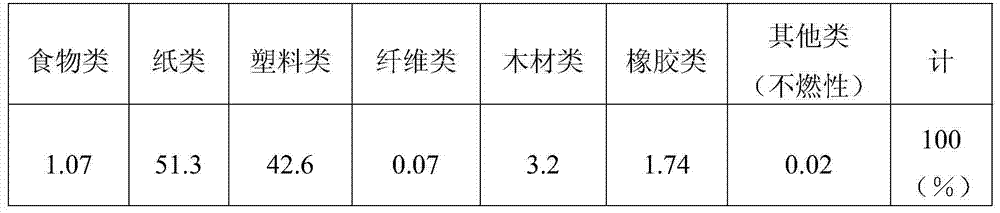

Embodiment 1

[0030] Making batches of 5m with Fe material 3 3.5t of livestock manure with a moisture content of 80-85% and 0.5-1t of paper municipal waste (MSW) were put into the reactor as soon as possible, and the input port at the upper part of the reactor was closed. Simultaneously with the completion of the feeding, livestock manure and municipal waste were mixed, and steam at a temperature of 210° C. was supplied so that the internal pressure of the reactor was 23 atm. At this time, the injected saturated steam or superheated steam reaches the reaction conditions in about 3 to 5 minutes in the steam supply dedicated boiler in the upper part of the reactor prepared in advance, and the supply of steam is interrupted. Stirring was performed at a speed of 10 to 15 rpm so that a physicochemical reaction between the supplied water vapor and the target waste would occur. During the progress of the reaction, saturated steam or superheated steam was intermittently supplied to maintain the at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com