A liquid-drop-generation capillary microfluidic chip and a preparing method thereof

A microfluidic chip, capillary technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., to achieve the effect of efficient preparation and collection of tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

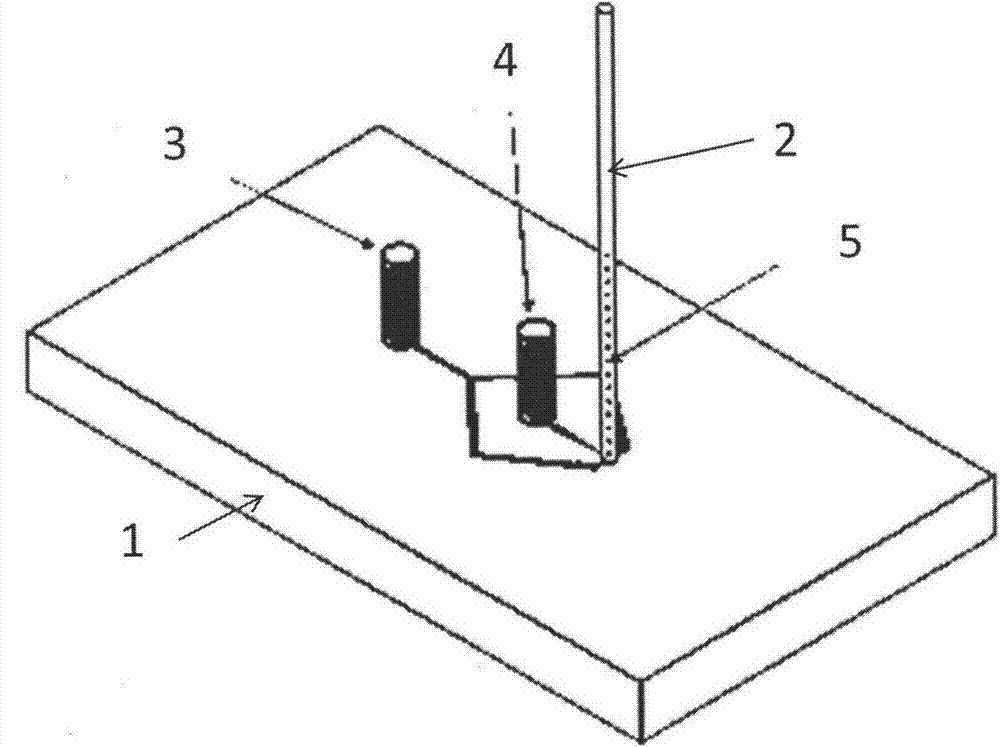

[0028] see figure 1 , the preparation steps of the water-in-oil droplet capillary microfluidic chip are as follows:

[0029] 1. Fabrication of the mask: first design and draw the microstructure and microchannel graphics of the droplet-generating capillary microfluidic chip with the design software (AutoCAD), and print the graphics into a mask, and use the mask to make a silicon wafer mold;

[0030] 2. Silicon wafer mold making: first clean the silicon wafer, and use concentrated H 2 SO 4 / H 2 o 2 =3:1, soak for 15min, then clean the wafer with absolute ethanol, acetone, and ultrapure water; dry the wafer on a heating plate; modify the wafer with hexamethyldisilazane, pour the photoresist AZ-50XT, drop glue at 2000rpm for 1min15s, then carry out pre-baking polymerization; place the mask and silicon wafer in the corresponding position of the photolithography machine, UV exposure, and finally develop;

[0031] 3. Fabrication of PDMS chips: use the prepared silicon wafer mold...

Embodiment 2

[0038] The preparation steps of capillary microfluidic chip for oil-in-water droplet generation are as follows:

[0039]1. Fabrication of the mask: first design and draw the microstructure and microchannel graphics of the droplet-generating capillary microfluidic chip with the design software (AutoCAD), and print the graphics into a mask, and use the mask to make a silicon wafer mold;

[0040] 2. Cleaning of glass substrate: use concentrated H 2 SO 4 / H 2 o 2 = 3:1, soak for 15min, then clean the wafer with absolute ethanol, acetone, and ultrapure water, and dry it on a heating plate;

[0041] 3. Sacrificial layer sputtering: Sputter a chromium layer with a thickness of 145nm on the surface of the cleaned glass substrate with an ion sputtering device;

[0042] 4. Pre-treatment of photolithography: After modifying the glass substrate with hexamethyldisilazane on the chromium plate glass, pour the photoresist AZ-4620, drop the glue at 3000rpm for 1min, and then carry out pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com