Method of utilizing supercritical CO2 extraction and macroporous resin adsorption separation to extract reserpine from rauvolfia verticillate

A technology of macroporous resin and reserpine, which is applied in the field of extraction and separation of reserpine in Rauwolfia, can solve the problems that are not conducive to industrial production, complicated process steps, high cost of adsorbent, etc., to shorten the production cycle and process The effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

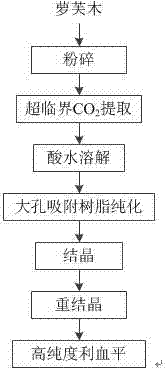

Image

Examples

Embodiment 1

[0026] Preparation of reserpine extract: crush 200g of Rauwolfia root bark, pass through a 10-mesh sieve, put the root powder in a supercritical extraction kettle for supercritical extraction, the temperature of the extraction kettle is 60°C, the pressure of the extraction kettle is 35 MPa, and the separation kettle The temperature of I is 45°C, the pressure of separation kettle I is 8 MPa, the temperature of separation kettle II is 35°C, the pressure of separation kettle II is 5 MPa, 40ml of 95% ethanol is added as entrainer, and the extraction time is 2h;

[0027] After combining the extracts obtained from the separation tank I and the separation tank II, dissolve them with 10% acetic acid (v / v) 50ml, filter and put on the HP-20 resin column, wash the 3 beds with water until neutral, and then use 3 The bed volume was eluted with 15% ethanol (v / v) and 4 bed volumes with 50% ethanol (v / v), and the 50% ethanol (v / v) eluate was collected and concentrated to dryness under reduced ...

Embodiment 2

[0031] Preparation of reserpine extract: crush 200g of Rauwolfia root bark, pass through a 10-mesh sieve, put the root powder in a supercritical extraction kettle for supercritical extraction, the temperature of the extraction kettle is 60°C, the pressure of the extraction kettle is 35 MPa, and the separation kettle The temperature of I is 45°C, the pressure of separation kettle I is 8 MPa, the temperature of separation kettle II is 35°C, the pressure of separation kettle II is 5 MPa, 40ml of 95% ethanol is added as entrainer, and the extraction time is 2h;

[0032] After combining the extracts obtained from the separation tank I and the separation tank II, dissolve them with 10% acetic acid (v / v), filter and put on the AB-8 resin column, wash 3 beds with water until neutral, and then use 3 beds Layer volume of 20% ethanol (v / v) and 5 bed volumes of 60% ethanol (v / v) were eluted, and the 60% ethanol (v / v) eluate was collected and concentrated to dryness under reduced pressure; ...

Embodiment 3

[0036] Preparation of reserpine extract: crush 200g of Rauwolfia root bark, pass through a 10-mesh sieve, put the root powder in a supercritical extraction kettle for supercritical extraction, the temperature of the extraction kettle is 60°C, the pressure of the extraction kettle is 30 MPa, and the separation kettle I temperature is 45°C, separation kettle I pressure is 10 MPa, separation kettle II temperature is 35°C, separation kettle II pressure is 5 MPa, 50ml of 95% ethanol is added as entrainer, and the extraction time is 2h;

[0037] After combining the extracts obtained from the separation tank I and the separation tank II, dissolve them with 10% acetic acid (v / v), filter and put them on the HP-20 resin column, wash 3 beds with water until neutral, and then use 3 beds Layer volume 15% ethanol (v / v) and 4 bed volumes 50% ethanol (v / v) were eluted, and 50% ethanol (v / v) eluate was collected and concentrated to dryness under reduced pressure;

[0038] Dissolve the solid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com