Photosensitive resin manufacture method and color filter

A technology of photosensitive resin and manufacturing method, which is applied in the photoengraving process of pattern surface, photosensitive materials and instruments used in opto-mechanical equipment, etc. Good developability, excellent thermal decomposition resistance and thermal yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

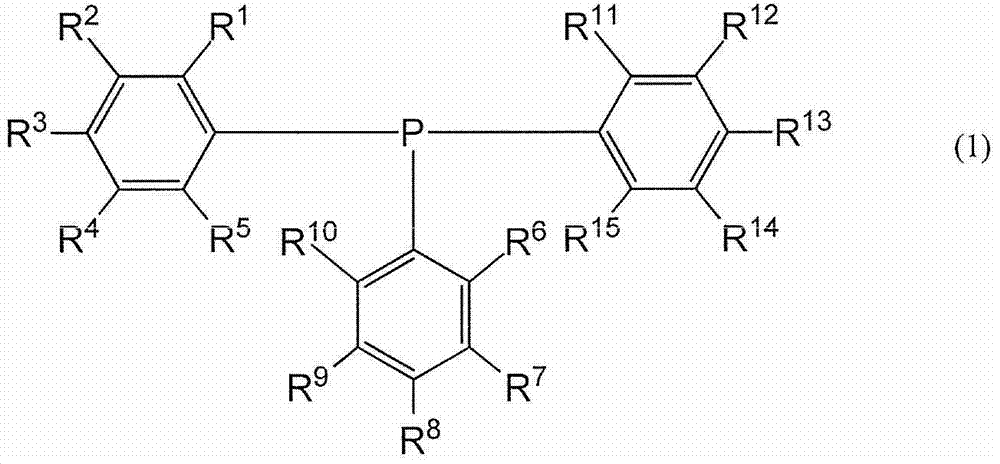

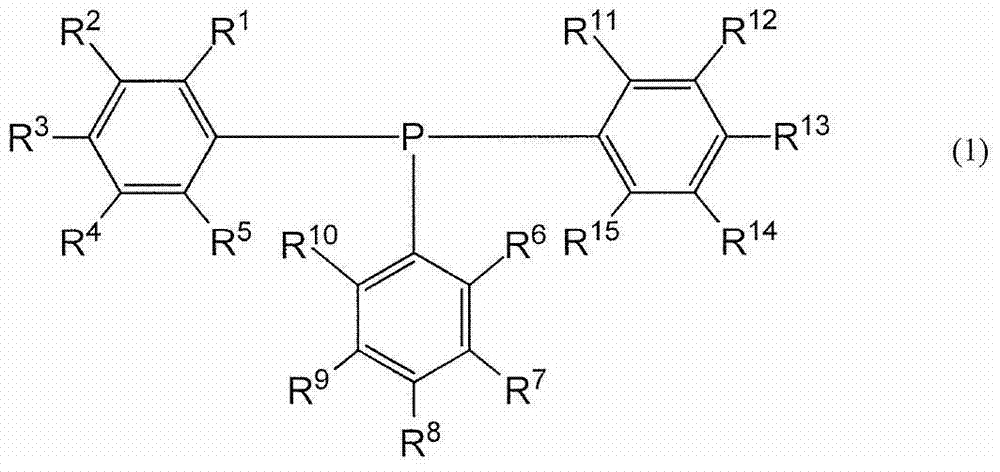

[0041] The method for producing a photosensitive resin (A-1) according to Embodiment 1 of the present invention is characterized in that a carboxyl group-containing copolymer and an epoxy group-containing ethylenically unsaturated compound are formed in three groups represented by the following formula (1). The reaction is performed at a temperature of 100° C. to 150° C. in the presence of a valent organophosphorus compound catalyst and a polymerization inhibitor in an atmosphere having an oxygen concentration of 2 v % to 10 v %.

[0042] [chemical formula 3]

[0043]

[0044] (where, R 1 ~R 15 Each independently represents a hydrogen atom, an alkyl group with 1 to 3 carbon atoms, an alkoxy group with 1 to 3 carbon atoms, an alkoxyalkyl group with 2 to 3 carbon atoms, or an alkyl group with 2 to 3 carbon atoms. 3 alkenyl; R 1 ~R 5 At least one of, R 6 ~R 10 at least one of the R 11 ~R 15 At least one of them is an alkyl group with 1 to 3 carbon atoms, an alkoxy group ...

Embodiment approach 2

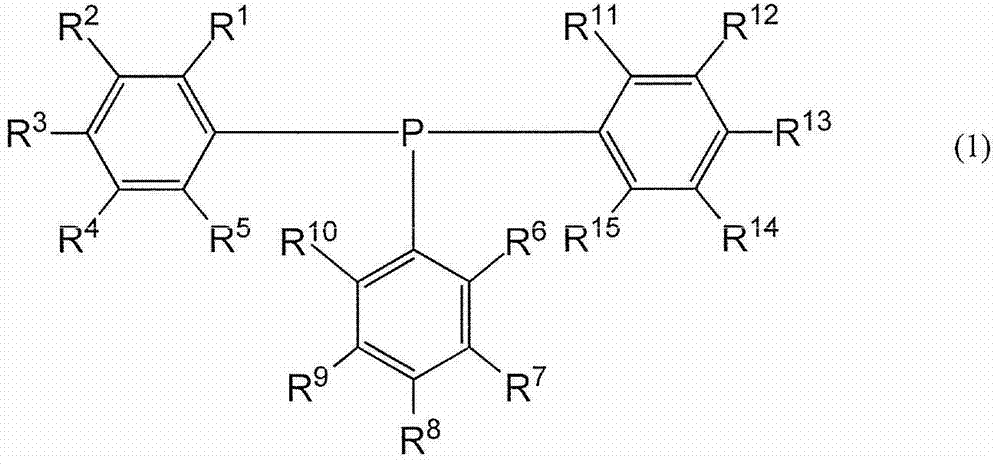

[0091]The method for producing a photosensitive resin (A-2) according to Embodiment 2 of the present invention is characterized in that an epoxy group-containing copolymer and a carboxyl group-containing ethylenically unsaturated compound are formed in three groups represented by the following formula (1). In the presence of a valent organophosphorus compound catalyst and a polymerization inhibitor, the reaction is performed at a temperature of 100°C to 150°C in an atmosphere having an oxygen concentration of 2v% to 10v%.

[0092] [chemical formula 4]

[0093]

[0094] (where, R 1 ~R 15 Each independently represents a hydrogen atom, an alkyl group having 1 to 3 carbon atoms, an alkoxy group having 1 to 3 carbon atoms, an alkoxyalkyl group having 2 to 3 carbon atoms, or an alkene having 2 to 3 carbon atoms Base; R 1 ~R 5 At least one of, R 6 ~R 10 at least one of the R 11 ~R 15 At least one of them is an alkyl group having 1 to 3 carbon atoms, an alkoxy group having ...

Embodiment 1

[0119] 569.9 g of propylene glycol monomethyl ether acetate was put into the flask equipped with the stirring device, the dropping funnel, the condenser, the thermometer, and the gas introduction tube, and it heated up to 120 degreeC, stirring with nitrogen substitution. Next, 63.5 g of peroxide was added to a monomer mixture consisting of 519.5 g (3.66 mol) of glycidyl methacrylate, 230 g (1.05 mol) of tricyclodecanyl methacrylate, and 54.4 g (0.52 mol) of styrene. - tert-butyl 2-ethylhexanoate (polymerization initiator, manufactured by NOF Corporation, PERBUTYL (registered trademark) O), and the obtained mixture was dropped into the above-mentioned flask from the dropping funnel over 2 hours. After completion|finish of dripping, it stirred further at 120 degreeC for 2 hours, and copolymerization reaction was performed, and the epoxy group containing copolymer solution was produced|generated. Add 252 g of acrylic acid, 3.2 g (0.3 parts by mass) of butyl hydroxytoluene as a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com