Plant molluscicide as well as preparation method and application thereof

The technology of a molluscicide and a plant is applied in the field of the preparation of a molluscicide for killing Fushou snails and the preparation of a plant molluscicide. The effect of low cost, low price and low toxicity of snail control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

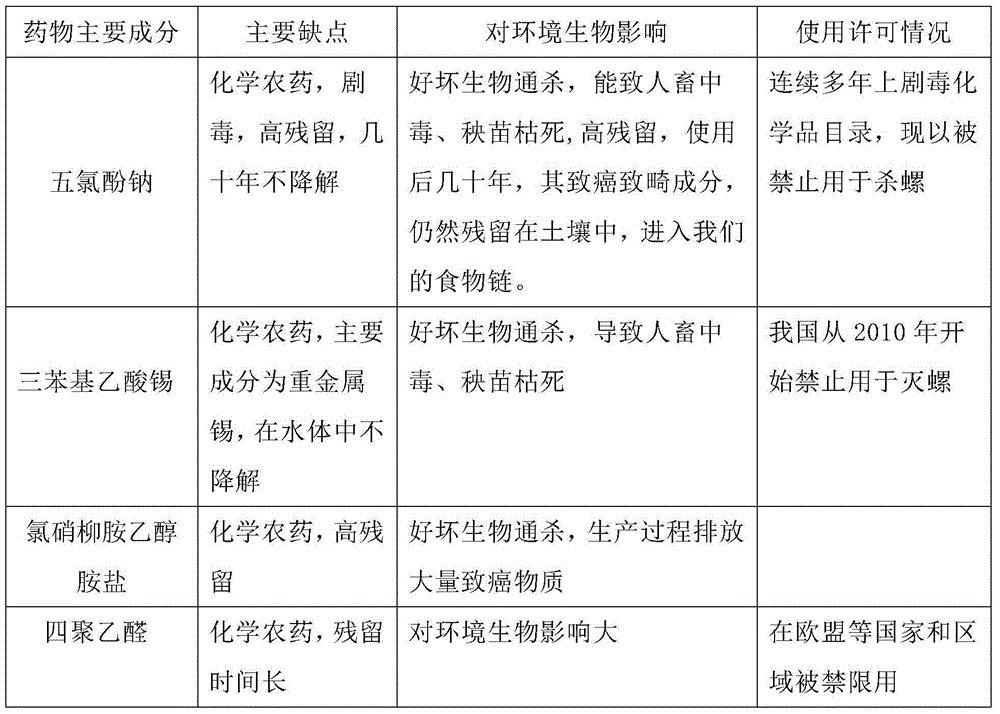

Problems solved by technology

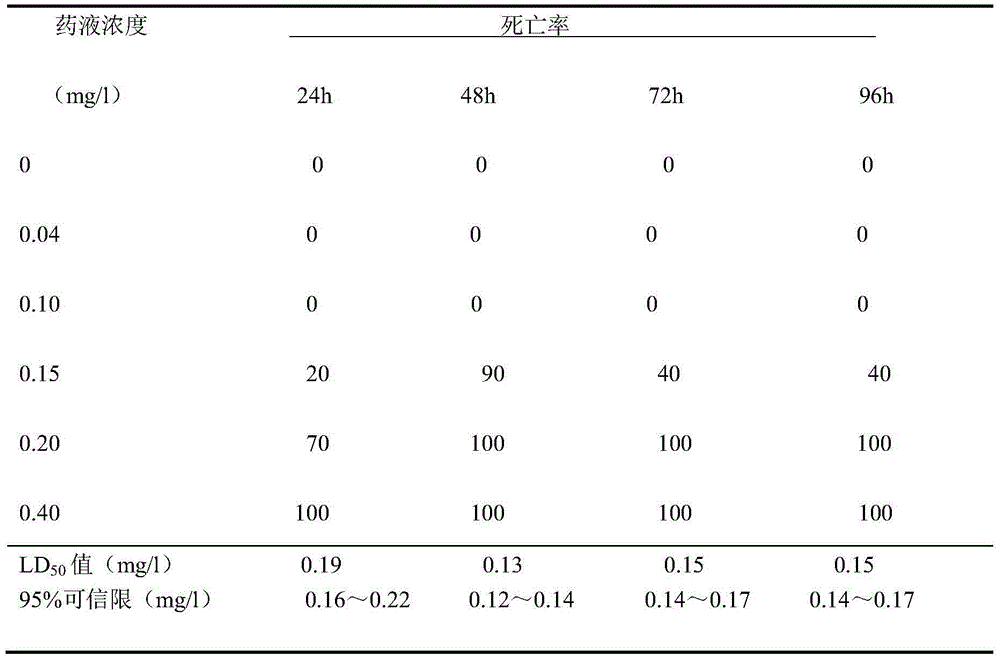

Method used

Image

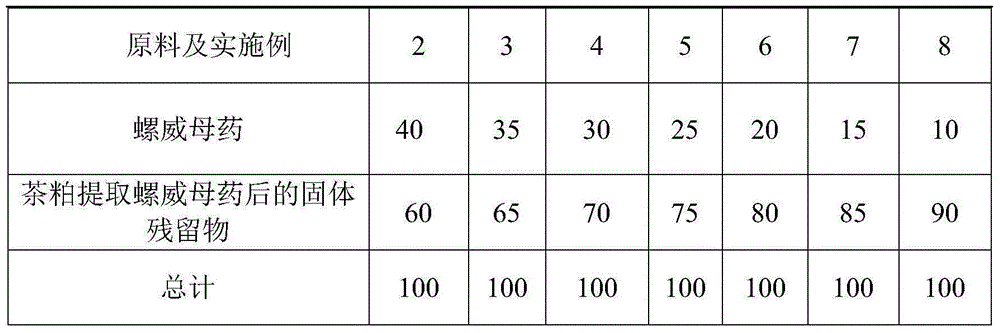

Examples

Embodiment 1

[0049] A plant molluscicide, which consists of the following components by weight percentage:

[0050] Spirocarb 8%

[0051] The solid residue after extraction of snail carburage with tea meal is 92%.

[0052] The preparation method of above-mentioned plant molluscicide comprises the steps:

[0053] 1) Select the tea meal whose content of pentacyclic triterpenoids is 8%-12%, and use No. 6 solvent oil to remove the residual oil in the tea meal (the oil content is lower than 2%).

[0054] 2) Pulverize the degreased tea meal to obtain tea meal powder, then add the tea meal powder to a 12% sodium hydroxide solution whose weight is 5.5 times the weight of the tea meal powder, and soak at 95°C After 4.5 hours to obtain the soaking solution, add alkaline protease with a weight of 12.5% of the soaking solution to the soaking solution, soak at 60°C for 12 hours, filter to obtain the filtrate and filter cake, dry the filter cake to obtain tea The solid residue after extracting snai...

Embodiment 10

[0110] A plant molluscicide, which consists of the following components by weight percentage:

[0111] Spirocarb 20%

[0112] 80% of the solid residue after extracting snail carburage with tea meal.

[0113] The preparation method of above-mentioned plant molluscicide comprises the steps:

[0114] 1) Select the tea meal whose content of pentacyclic triterpenoids is 8%-12%, and use No. 6 solvent oil to remove the residual oil in the tea meal (the oil content is lower than 2%).

[0115] 2) Pulverize the degreased tea meal to obtain tea meal powder, then add the tea meal powder to an 18% sodium hydroxide solution whose weight is 5 times the weight of the tea meal powder, and soak at 105°C After 4 hours, the soaking solution was obtained, and then alkaline protease with a weight of 5% of the soaking solution was added to the soaking solution, soaked at 55°C for 14 hours, filtered to obtain the filtrate and filter cake, and the filter cake was dried to obtain tea The solid resid...

Embodiment 11

[0119] A plant molluscicide, which consists of the following components by weight percentage:

[0120] Spirocarb 40%

[0121] 60% of the solid residue after extracting snail carburage with tea meal.

[0122] The preparation method of above-mentioned plant molluscicide comprises the steps:

[0123] 1) select the tea meal whose content of pentacyclic triterpenoids is 8%-12%, and remove the residual oil in the tea meal with No. 6 solvent oil (the oil content is lower than 2%);

[0124] 2) Pulverize the degreased tea meal to obtain tea meal powder, then add the tea meal powder to a 5% sodium hydroxide solution whose weight is 6 times the weight of the tea meal powder, and soak at 85°C After 4 hours, the soaking liquid was obtained, and then alkaline protease with a weight of 20% of the weight of the soaking liquid was added to the soaking liquid, soaked at 75°C for 10 hours, filtered to obtain the filtrate and filter cake, and the filter cake was dried to obtain tea The solid r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com