Preparation method of modified activated carbon used for heavy metal wastewater treatment

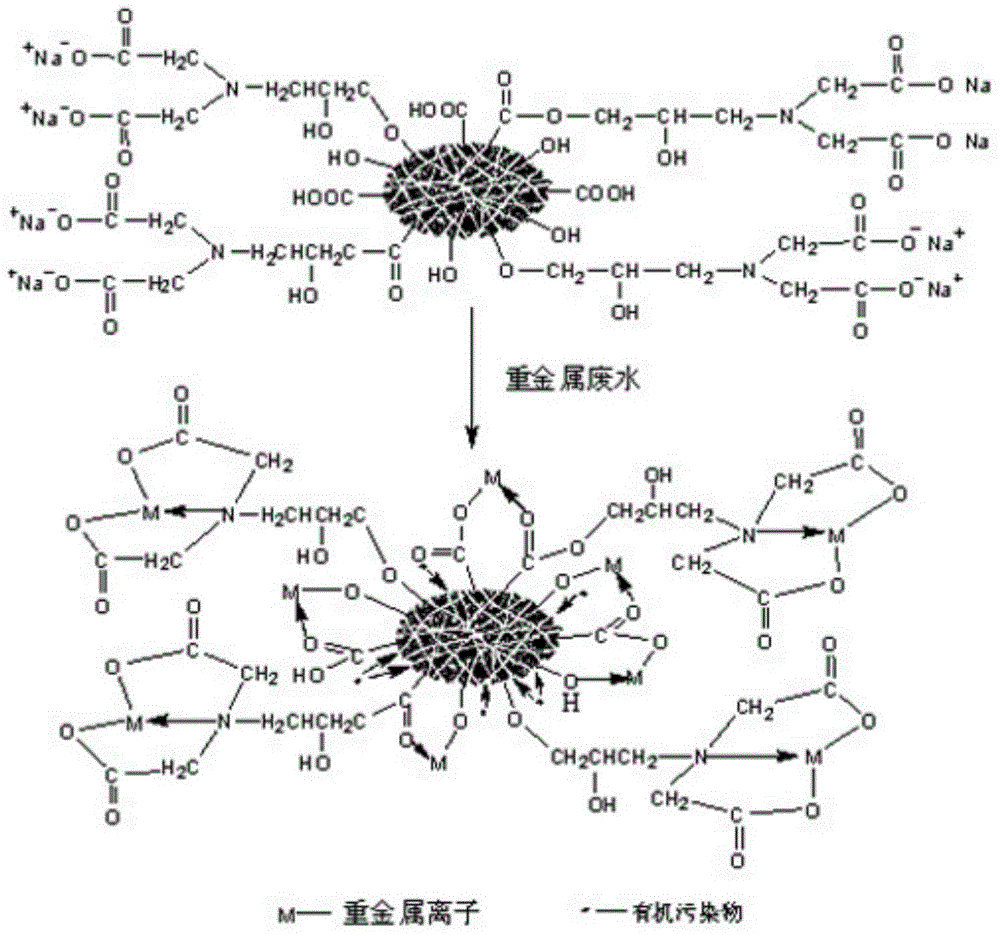

A wastewater treatment and activated carbon technology, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of unfavorable ion transport activated carbon regeneration, treatment effect not meeting requirements, and damage to the pore structure and other issues, to achieve the ability to strongly adsorb heavy metals and organic pollutants, remove heavy metal ion pollution, and remove organic pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

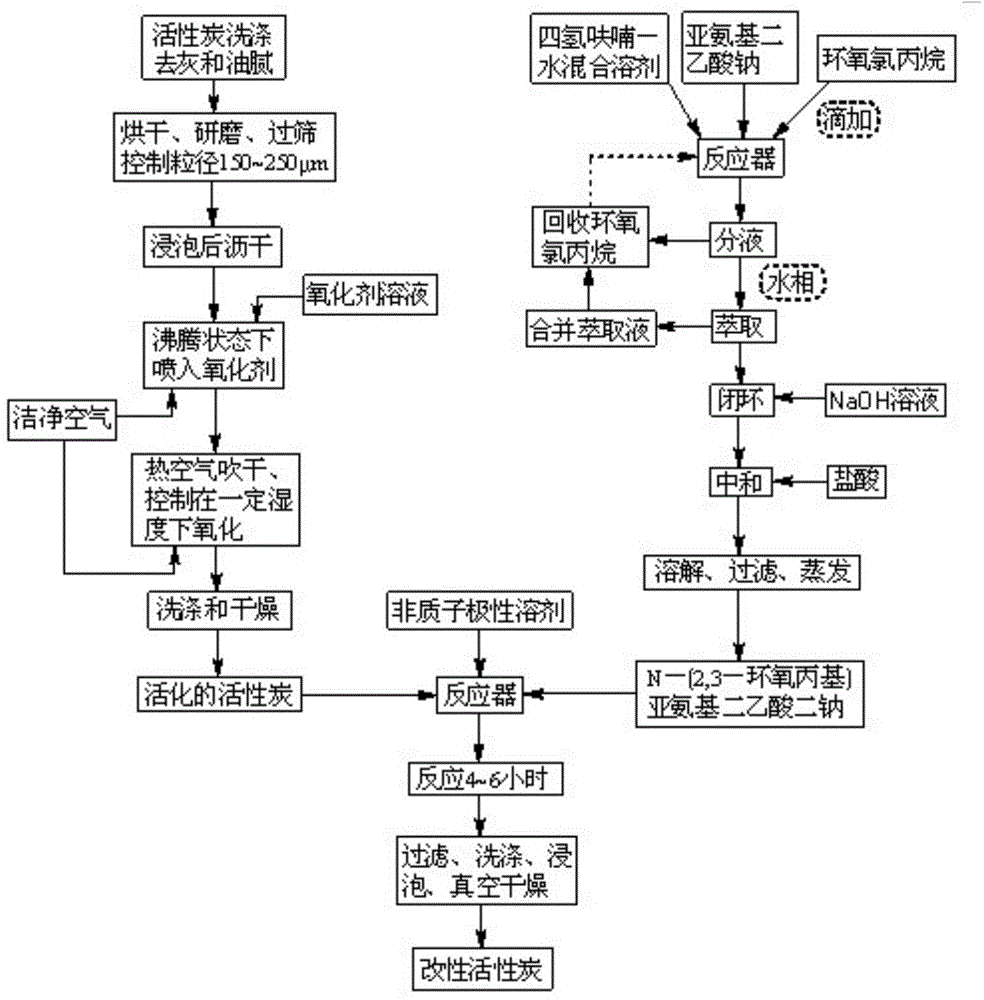

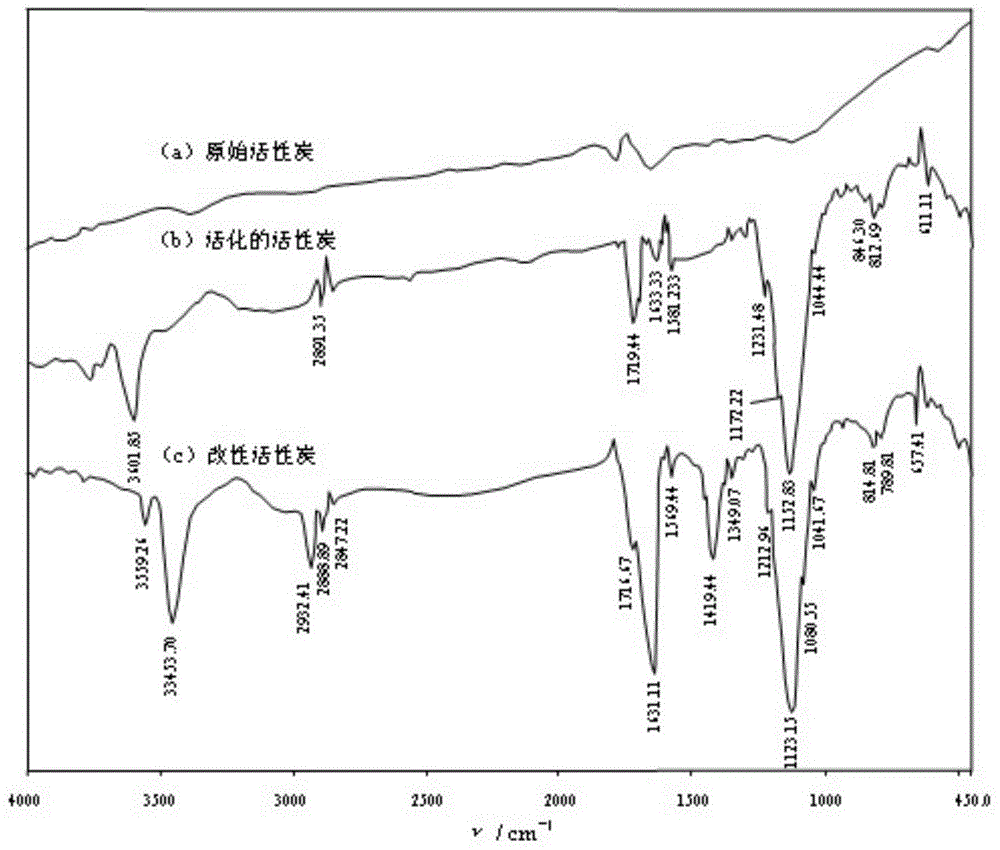

Method used

Image

Examples

Embodiment 1

[0036] (1) Take 100g of fruit shell activated carbon and wash the surface with distilled water, then ultrasonically clean it for 30 minutes, then wash it with distilled water, and dry it at 120°C to constant weight; then grind it, pass it through 60 mesh and 100 mesh sieve respectively, and take a 60 mesh sieve Control the particle size of the activated carbon at 150-250 μm for the lower matter and the upper matter of a 100-mesh sieve; then take 40 g of activated carbon and immerse in distilled water for 60 minutes, take it out and drain until there is no obvious water mark on the surface;

[0037] (2) the activated carbon of step (1) gained is packed in the boiling sprinkler, feed clean air from the bottom of the device and the activated carbon particles are blown to boiling state, spray 8.0mol / L nitric acid solution for 2 minutes by the top of the upper cone, and then Blow hot air at 60°C from the bottom until there is no obvious water trace on the surface; transfer to a clos...

Embodiment 2

[0045] (1) Take 100g of fruit shell activated carbon and wash the surface with distilled water, then ultrasonically clean it for 30 minutes, then wash it with distilled water, and dry it at 110°C to constant weight; then grind it, pass it through 60 mesh and 100 mesh sieve respectively, and take a 60 mesh sieve Control the particle size of the activated carbon at 150-250 μm for the lower matter and the upper matter of a 100-mesh sieve; then take 40 g of activated carbon and soak in distilled water for 50 minutes, take it out and drain until there is no obvious water mark on the surface;

[0046] (2) the gac of step (1) gained is packed in the boiling sprinkler, feed clean air from the bottom of the device and the gac particles are blown to a boiling state, spray 6.0mol / L nitric acid solution for 2 minutes by the top of the upper cone, and then Blow hot air at 50°C from the bottom until there is no obvious water trace on the surface; transfer to a closed stainless steel containe...

Embodiment 3

[0051] (1) Take 100g of fruit shell activated carbon and wash the surface with distilled water, then ultrasonically clean it for 30 minutes, then wash it with distilled water, and dry it at 100°C to constant weight; then grind it, pass it through 60 mesh and 100 mesh sieve respectively, and take 60 mesh sieve Control the particle size of the activated carbon at 150-250 μm for the lower matter and the upper matter of a 100-mesh sieve; then take 40 g of activated carbon and soak in distilled water for 40 minutes, take it out and drain until there is no obvious water mark on the surface;

[0052] (2) the gac of step (1) gained is packed in the boiling sprinkler, pass into clean air from the bottom of the device and the gac particles are blown to a boiling state, spray 10.0mol / L nitric acid solution for 2 minutes by the top of the upper cone, and then Blow hot air at 55°C from the bottom until there is no obvious water trace on the surface; transfer to a closed stainless steel cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com