Preparation method of metal soft magnetic compound materials, chip component and manufacturing method of chip component

A composite material and metal soft magnetic technology, which is applied in the direction of electrical components, inductance/transformer/magnet manufacturing, inductors, etc., can solve the problems of insulation withstand voltage performance and heat resistance stability, etc., and achieve good performance. Effects of magnetic properties, high insulation withstand voltage, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

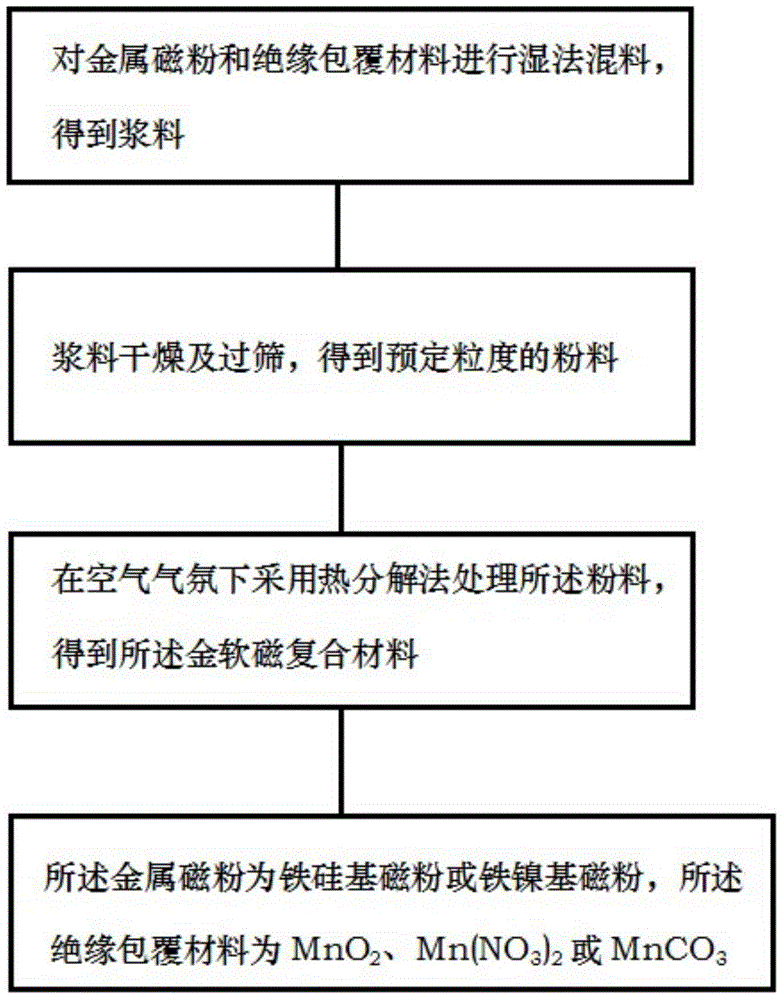

[0030] A method for preparing a metal soft magnetic composite material, comprising the steps of:

[0031] The metal magnetic powder and the insulating coating material are wet-mixed to obtain a slurry; the slurry is dried and sieved to obtain a powder with a predetermined particle size; the powder is treated by a thermal decomposition method in an air atmosphere to obtain the gold Soft magnetic composite material; the metal magnetic powder is iron-silicon-based magnetic powder or iron-nickel-based magnetic powder, and the insulating coating material is MnO 2 , Mn(NO 3 ) 2 or MnCO 3 .

[0032] Wherein, the amount of the insulating coating material is 1wt%-6wt% of the metal magnetic powder. Described sieving adopts the sieve cloth of 30 meshes or more. The thermal decomposition treatment is carried out at 500-800°C. The wet mixing is carried out according to the weight ratio of metal magnetic powder:zirconia ball:absolute ethanol=(8-12):(4-6):1.

[0033] Mix the additives...

example 1

[0036] 1. Metal magnetic powder sieving:

[0037] Sieve the metal magnetic powder with a 500-mesh sieve, and the metal magnetic powder iron in this example is silicon chromium magnetic powder.

[0038] 2. Wet mixing of metal magnetic powder and insulating coating material:

[0039] According to the ratio of metal magnetic powder: zirconia ball: dehydrated alcohol=10:5:1, put it into the chamfering tank after weighing, and then add the insulating coating material MnO of 4wt% metal magnetic powder 2 , after sealing the above chamfering tank, put it into the chamfering frame and mix the materials for 18 hours to obtain the slurry.

[0041] Pour the above mixed slurry into a glass beaker, and then place the glass beaker in a rotating device with a heating device inclined at an angle of 45 degrees for rotation and drying. The rotating speed of the rotating device can be 100 rpm. The temperature of the device is controlled within the range of 50-60 degr...

example 2

[0049] The difference from the aforementioned example 1 is that the metal magnetic powder in the first step is an iron-nickel alloy material, and the metal magnetic powder added in the second step is 6wt% MnCO 3 , in the step five, the metal soft magnetic composite material is placed in an environment of 550° C. for about 120 minutes.

[0050] Similarly, the metal soft magnetic composite material obtained above is added to 2wt% PVB binder of the powder, and a magnetic ring with an outer diameter of 8 mm, an inner diameter of 5 mm, and a thickness of about 2.3 mm is made under a pressure of 1800 MPa by a dry pressing molding process. Then, in a vacuum environment, the magnetic ring was kept at 900°C for 2 hours to prepare the sintered magnetic ring of the above embodiment.

[0051] The sintered magnetic ring sample prepared by the above example 1 and example 2 is tested for the following properties:

[0052] (1) The initial permeability of the sintered magnetic ring at 1MHz

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com