Apparatus and method for producing biosynthesis gas

A biosynthesis and carrier gas technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of large area, difficult to scale up production, and unguaranteed continuity of feeding devices, so as to improve the transformation Efficiency, to achieve the effect of condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

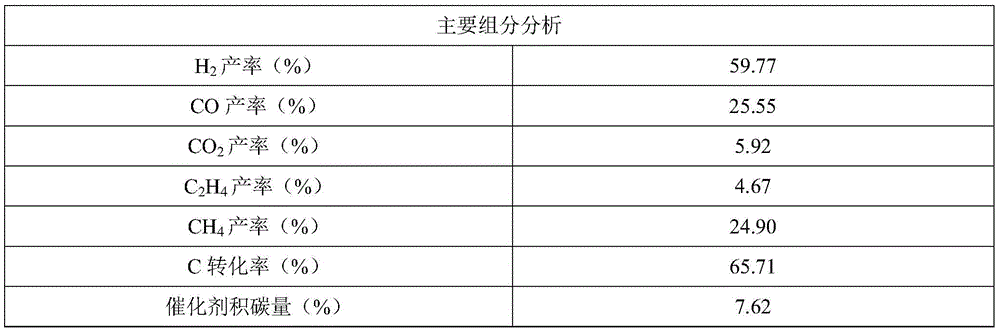

Embodiment 1

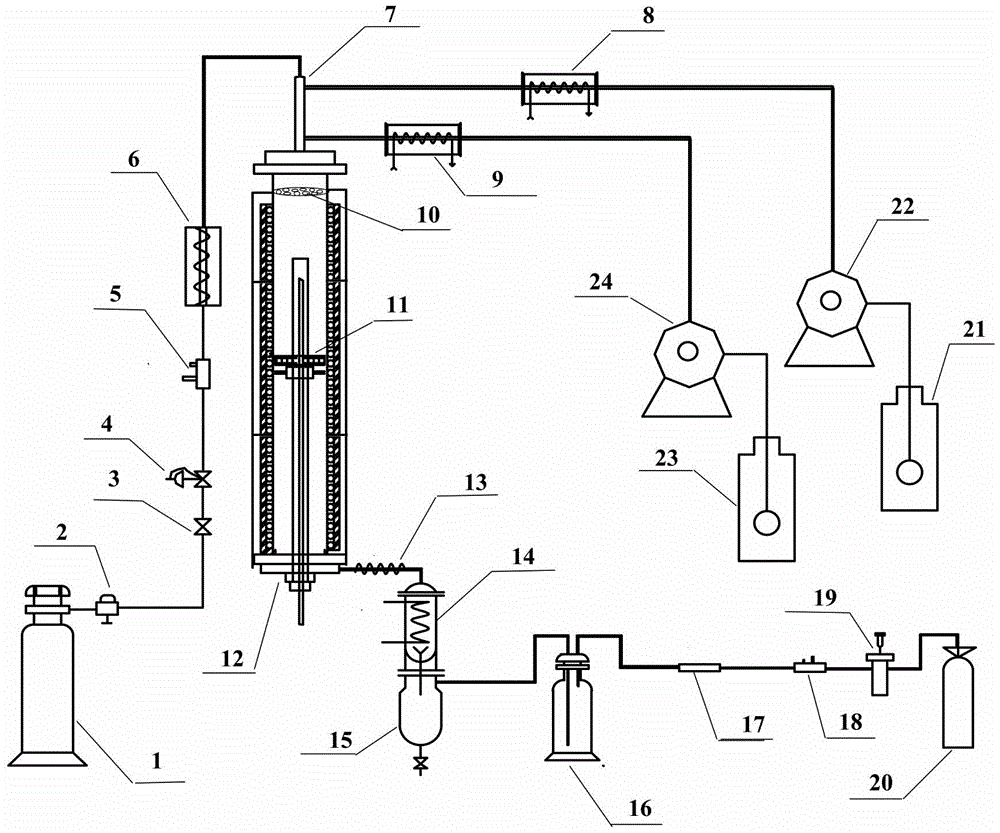

[0029] A method for preparing biosynthesis gas, comprising the steps of:

[0030] (1) Use a device for preparing biosynthesis gas; the product gas collection container is disconnected from the pipeline that is connected to the gas sampling valve 19 at the other end, and the catalyst zeolite is placed on the catalytic bed partition 11 to adjust the temperature of the first preheater 6 to 350°C; adjust the temperature in the gasifier 12 to be 700°C; adjust the temperature of the second preheater 8 to be 340°C; adjust the temperature of the third preheater 9 to be 400°C; adjust the temperature of the heating jacket 13 to be 300°C; adjust the temperature of the gas-liquid separator 14 to be -5°C;

[0031] (2) Open pressure reducing valve 2, first cut-off valve 3, back pressure valve 4, by adjusting the first gas flowmeter 5, make the carrier gas of carrier gas bottle 1 pass through the first preheater with the gas velocity of 500ml / min 6. After the mixing chamber 7 enters the gas...

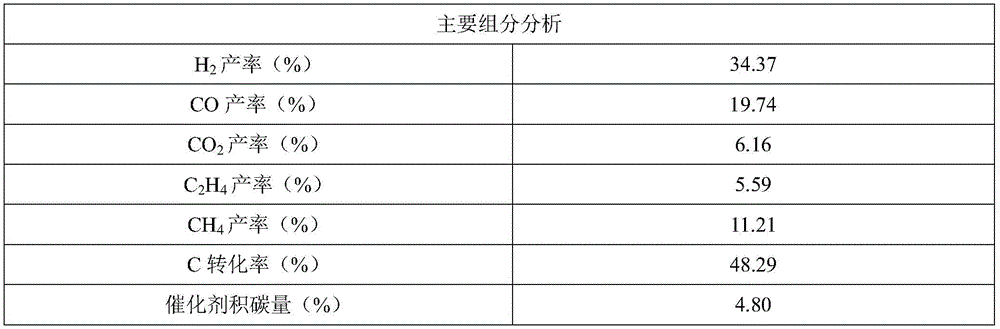

Embodiment 2

[0037] A method for preparing biosynthesis gas, comprising the steps of:

[0038] (1) Use a device for preparing biosynthesis gas; the product gas collection container is disconnected from the pipeline that is connected to the gas sampling valve 19 at the other end, and the catalyst ferric oxide is placed on the catalytic bed dividing plate 11, and the first preheater is adjusted The temperature of 6 is 300°C; the temperature in the gasifier 12 is adjusted to 600°C; the temperature of the second preheater 8 is adjusted to 300°C; the temperature of the third preheater 9 is adjusted to 300°C; the heating jacket 13 is adjusted The temperature is 200°C; the temperature of the gas-liquid separator 14 is adjusted to be -10°C;

[0039] (2) Open pressure reducing valve 2, the first stop valve 3, back pressure valve 4, by adjusting the first gas flow meter 5, the carrier gas of carrier gas bottle 1 is passed through the first preheater with the gas velocity of 200ml / min 6. After the m...

Embodiment 3

[0045] A method for preparing biosynthesis gas, comprising the steps of:

[0046] (1) Use the device for preparing biosynthesis gas; the product gas collection container is disconnected from the pipeline that is connected with the gas sampling valve 19 at the other end, and catalyst dolomite is placed on the catalytic bed dividing plate 11, and the temperature of the first preheater 6 is adjusted. The temperature is 400°C; the temperature in the gasifier 12 is adjusted to 800°C; the temperature of the second preheater 8 is adjusted to 380°C; the temperature of the third preheater 9 is adjusted to 450°C; the temperature of the heating jacket 13 is adjusted is 400°C; the temperature of the gas-liquid separator 14 is adjusted to be 0°C;

[0047] (2) Open the pressure reducing valve 2, the first cut-off valve 3, the back pressure valve 4, and by adjusting the first gas flow meter 5, the carrier gas of the carrier gas bottle 1 is passed through the first preheater at a gas velocity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com