Method for preparing nano Co2(OH)3Cl gas sensitive material by ultrasonic-microwave hydrothermal method and application

A technology of microwave hydrothermal method and gas-sensitive materials, which is applied in nanotechnology, nanotechnology, material resistance, etc., can solve the problems of unsatisfactory nanomaterials and high energy consumption, and achieve uniform shape distribution, high reactivity, and shortened The effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

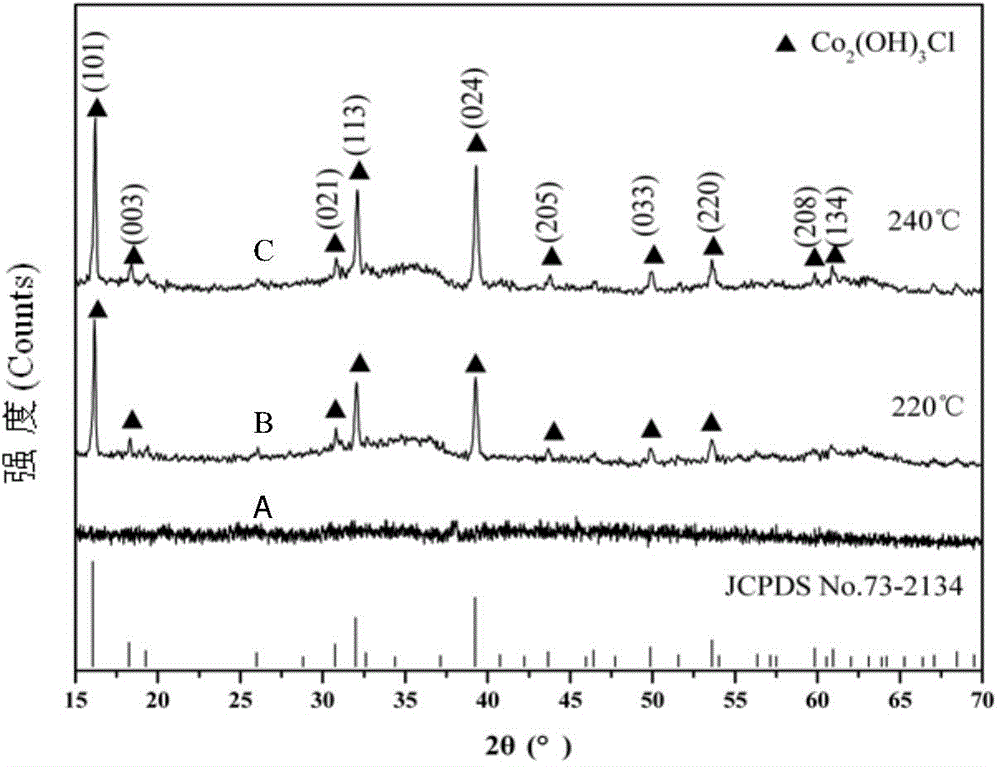

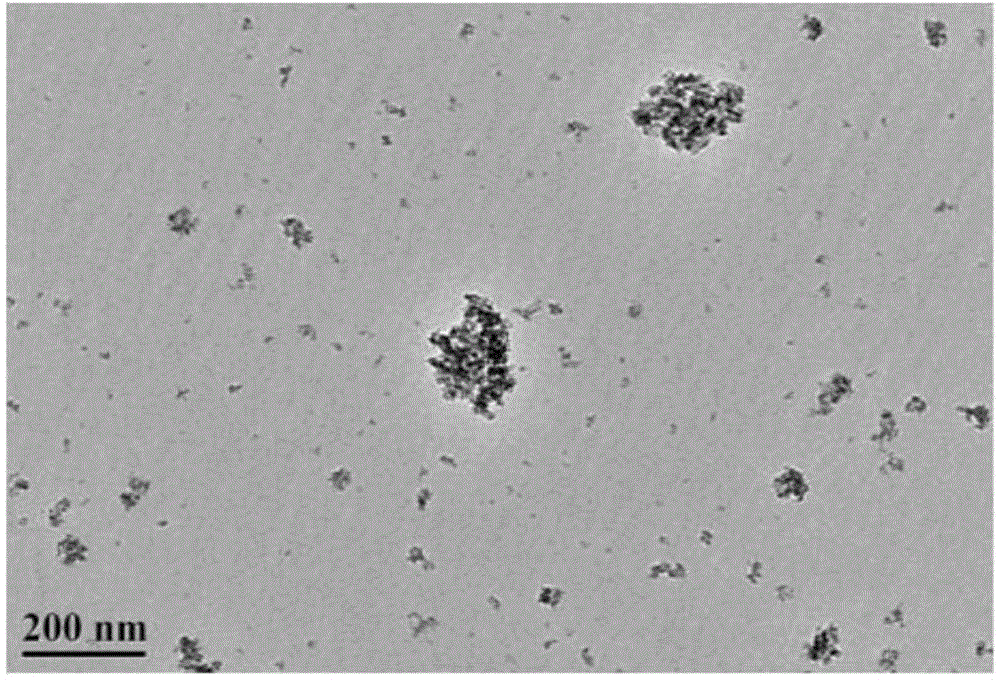

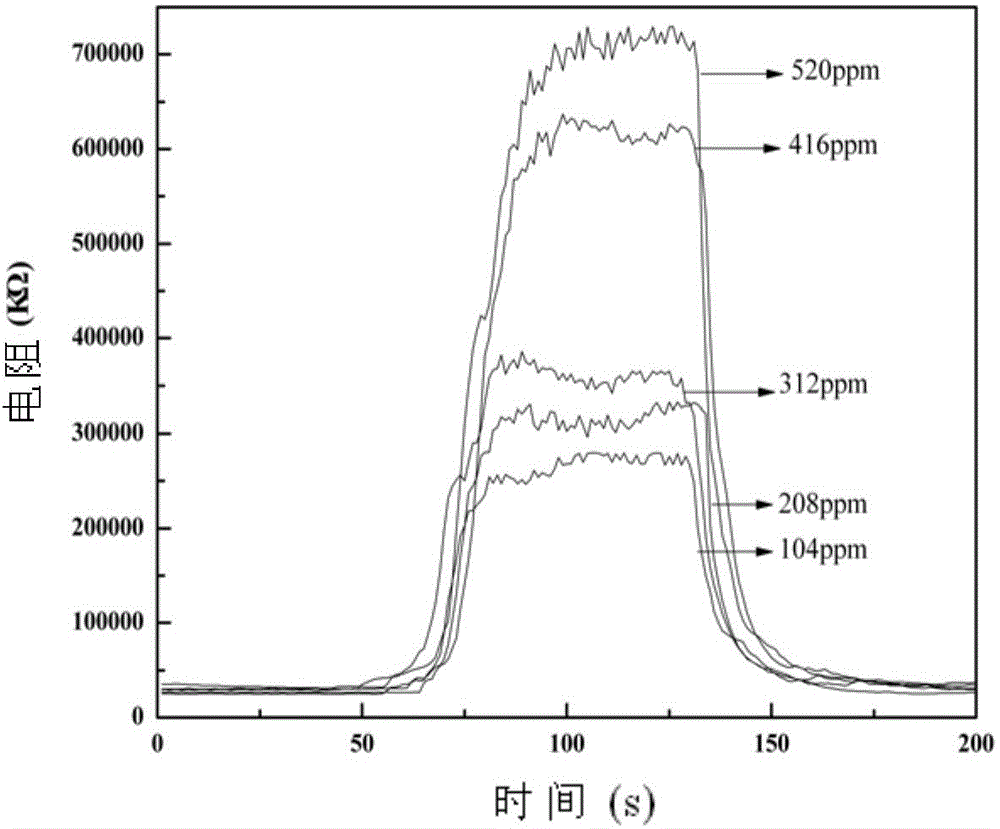

[0033] 1. Preparation of nano-Co by ultrasonic-microwave hydrothermal method 2 (OH) 3 Cl gas sensitive material

[0034] 1) Analytical pure cobalt acetate tetrahydrate (Co(CH 3 COO) 2 4H 2 O) dissolved in deionized water to prepare Co 2+ The concentration is 1 μmol L -1 solution A; to solution A was added TiCl as a catalyst 3 hydrochloric acid solution, and then ultrasonically pretreated at 100W for 10min to obtain Co 2+ The concentration is 0.7μmol·L -1 Precursor B; among them, TiCl 3 The hydrochloric acid solution is composed of TiCl with a volume ratio of 1:1 3 and 6mol L -1 mixed with hydrochloric acid;

[0035] 2) Use analytically pure ammonia water to adjust the pH value of precursor B to 5.0, and then add it to the reaction kettle, the filling degree of the reaction kettle is less than 50%; react under microwave hydrothermal conditions, after the reaction is completed, the reaction kettle is obtained The reaction system was cooled to below 60°C, and then the...

Embodiment 2

[0041] 1. Preparation of nano-Co by ultrasonic-microwave hydrothermal method 2 (OH) 3 Cl gas sensitive material

[0042] 1) Analytical pure cobalt acetate tetrahydrate (Co(CH 3 COO) 2 4H 2 O) dissolved in deionized water to prepare Co 2+ The concentration is 10 μmol L -1 solution A, add TiCl as a catalyst to solution A 3 hydrochloric acid solution, and then ultrasonically pretreated at 200W for 10min to obtain Co 2+ The concentration is 7 μmol L -1 Precursor B; among them, TiCl 3 The hydrochloric acid solution is composed of TiCl with a volume ratio of 1:5 3 and 6mol L -1 mixed with hydrochloric acid;

[0043] 2) Use analytically pure ammonia water to adjust the pH value of precursor B to 8.0, and then add it to the reactor, and the filling degree of the reactor is less than 50%; react under microwave hydrothermal conditions, and after the reaction is completed, obtain The reaction system was cooled to below 60°C, and then the product in the reaction system in the ...

Embodiment 3

[0049] 1. Preparation of nano-Co by ultrasonic-microwave hydrothermal method 2 (OH) 3 Cl gas sensitive material

[0050] 1) Analytical pure cobalt acetate tetrahydrate (Co(CH 3 COO) 2 4H 2 O) dissolved in deionized water to prepare Co 2+ The concentration is 20μmol L -1 solution A, add TiCl as a catalyst to solution A 3 hydrochloric acid solution, and then ultrasonically pretreated at 50W for 20min to obtain Co 2+ The concentration is 15 μmol L -1 Precursor B; among them, TiCl 3 The hydrochloric acid solution is composed of TiCl with a volume ratio of 1:8 3 and 6mol L -1 mixed with hydrochloric acid;

[0051] 2) Use analytically pure ammonia water to adjust the pH value of precursor B to 10.0, and then add it to the reaction kettle, the filling degree of the reaction kettle is less than 50%; react under microwave hydrothermal conditions, after the reaction is completed, the reaction kettle is obtained The reaction system was cooled to below 60°C, and then the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com