Reinforced plasterboard and preparation method thereof

A gypsum board and gypsum-based technology, applied in the field of building materials, can solve problems such as difficult cleaning and maintenance, mildew, and potential safety hazards, and achieve the effects of resource reuse, proper final setting, and improved flexural resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] 1) Preparation of gypsum substrate layer 1 slurry: Mix 72kg of α-high-strength desulfurized gypsum powder, 3kg of bisphenol A epoxy resin, 0.1kg of citric acid, 0.5kg of acrylic acid emulsion, and 24.4kg of water, and stir them evenly to obtain a gypsum slurry .

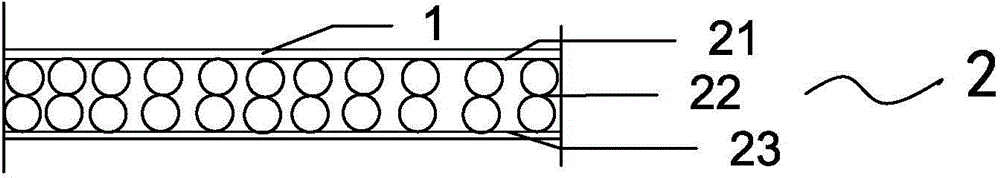

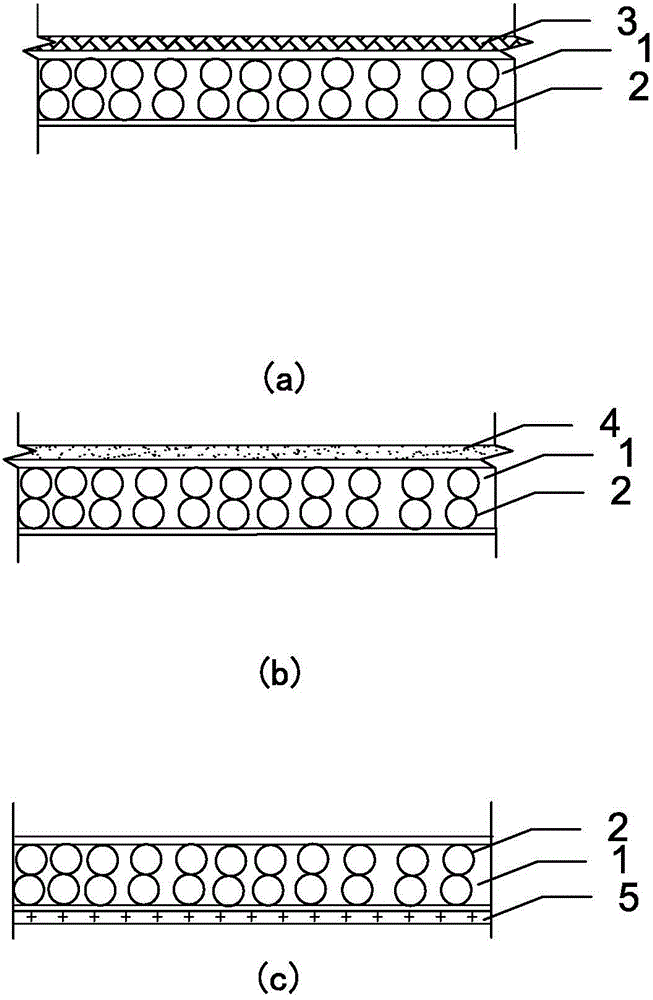

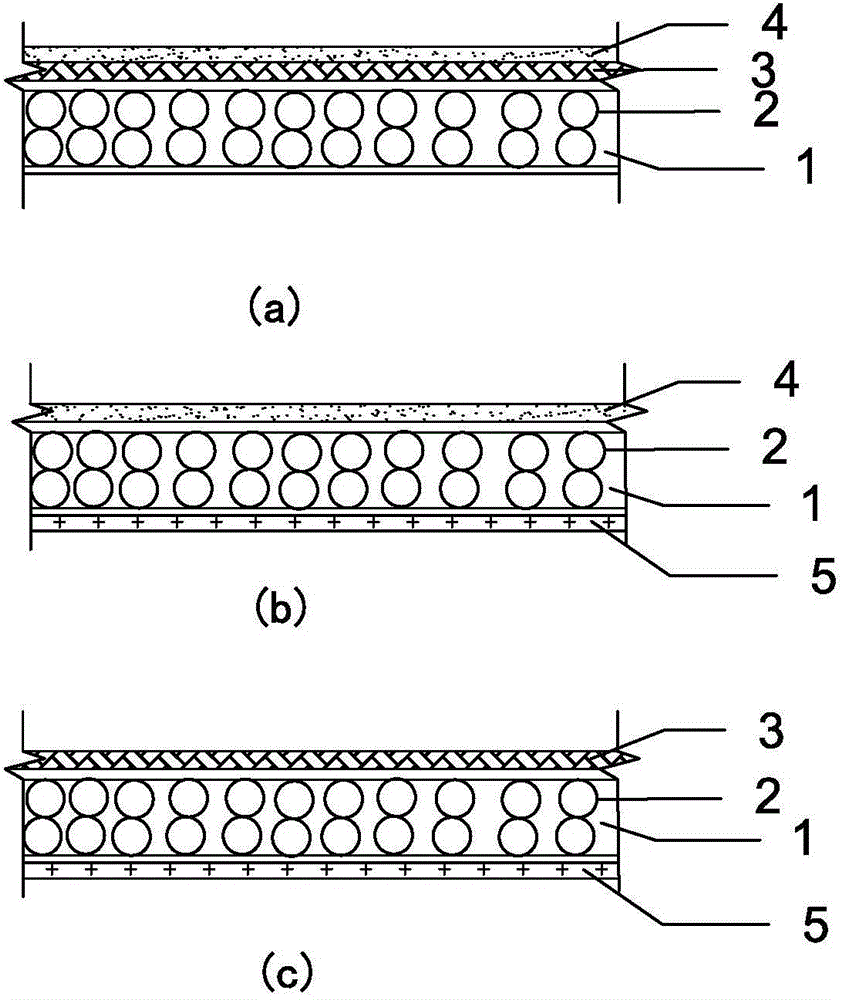

[0121] 2) Forming of gypsum substrate layer 1: apply a layer of release agent inside the mold, and then spray the above-mentioned gypsum slurry. After the initial setting of the gypsum slurry, put in the three-dimensional reinforced fiber fabric 2, then slowly pour in the remaining gypsum slurry, shake it gently until the surface is smooth and clean, and then let it stand for a period of time. The three-dimensional reinforced fiber fabric 2 is made of glass fiber. into, the height of the middle layer 22 is 12mm.

[0122] 3) Curing of the gypsum base material layer 1: After the formed gypsum base material layer is cured at room temperature for 4 hours, demoulding is performed; the demoulded product is placed i...

Embodiment 2

[0125] 1) Preparation of gypsum substrate layer 1 slurry: 70kg of α-high-strength desulfurized gypsum powder, 6kg of polyimide, 3kg of phenolic epoxy resin, 0.1kg of citric acid, 0.4kg of acrylic acid emulsion, and 20.5kg of water were fully stirred to obtain Gypsum slurry.

[0126] 2) Forming of gypsum substrate layer 1: apply a layer of release agent inside the mold, and then spray the above-mentioned gypsum slurry. After the initial setting of the gypsum slurry, put in the three-dimensional reinforced fiber fabric 2, then slowly pour in the remaining gypsum slurry, shake it gently until the surface is smooth and clean, and then let it stand for a period of time. The three-dimensional reinforced fiber fabric 2 is made of glass fiber. into, the height of the middle layer 22 is 12mm.

[0127] 3) Curing of the gypsum base material layer 1: After the formed gypsum base material layer is cured at room temperature for 4 hours, demoulding is performed; the demoulded product is pla...

Embodiment 3

[0131] 1) Preparation of gypsum substrate layer 1 slurry: 65kg α-high strength desulfurized gypsum powder, 8kg glass microspheres, 2kg redispersible latex powder, 0.2kg citrate, 0.1kg sodium tripolyphosphate, 26.7kg water, fully stirred Uniformly, a gypsum slurry is obtained.

[0132] 2) Forming of gypsum substrate layer 1: apply a layer of release agent inside the mold, and then spray the above-mentioned gypsum slurry. After the initial setting of the gypsum slurry, put in the three-dimensional reinforced fiber fabric 2, then slowly pour in the remaining gypsum slurry, shake it gently until the surface is smooth and clean, and then let it stand for a period of time. The three-dimensional reinforced fiber fabric 2 is made of glass fiber. into, the height of the middle layer 22 is 12mm.

[0133] 3) Curing of the gypsum base material layer 1: After the formed gypsum base material layer is cured at room temperature for 4 hours, demoulding is performed; the demoulded product is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com