Recycling method for waste PPS dedusting filter bag

A filter bag, waste technology, applied in the application field of polymer materials, can solve problems such as consumption of large water resources, land resource pollution, water environment pollution, etc., and achieve good compatibility, good mechanical properties and processing properties, and rheological properties. The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

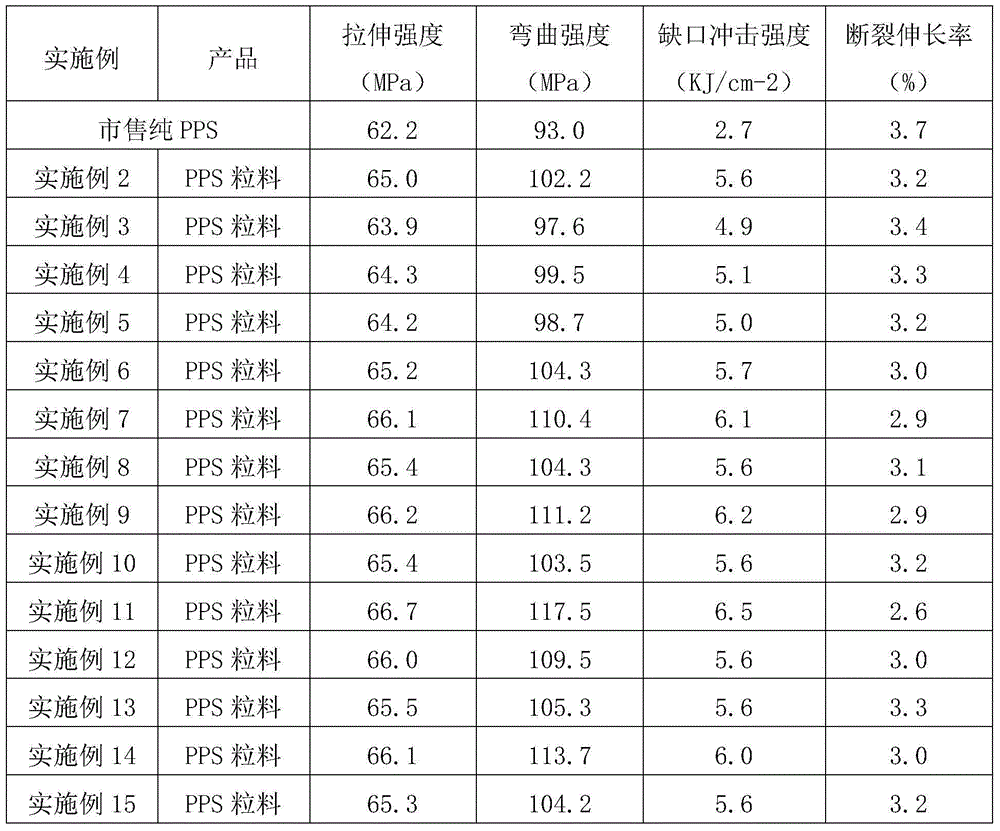

Examples

Embodiment 1

[0066] Remove the metal steel ring from the waste PPS dust filter bag, put it into an infrared drying machine and dry it at 150°C for 6 hours. After drying, the moisture content is less than 2%. Dust removal equipment, dust enters the collection bag, and the small pieces of non-woven fabric with a dust content of less than 3% enter the opening machine. In the opening machine, the non-woven fabric sample is opened into fibers, and the dust generated during the opening process enters the collection bag. , The fiber sample enters the shredder to be shredded into short fibers with a fiber length less than 2mm.

Embodiment 2

[0068] Add 50 kilograms of short fibers obtained in Example 1 into a 500-liter high-speed mixer, add 150 grams of antioxidant 1098, add 50 grams of zinc oxide, and add 250 grams of KH550. After mixing in a high-speed mixer for 5 minutes, discharge. Dry, with water content less than 0.2%. The dried material is melt extruded and granulated in a twin-screw extruder to obtain PPS pellets. The temperature in each zone of the twin-screw extruder is: zone 1 290°C, zone 2 290°C, zone 3 300°C, head 310°C; screw speed 120rpm, aspect ratio L / D=30 / 1.

Embodiment 3

[0070] Add 50 kilograms of short fibers obtained in Example 1 into a 500-liter high-speed mixer, add 100 grams of antioxidant 1010 and 50 grams of 168, add 50 grams of zinc oxide, and add 500 grams of KH550. After mixing in a high-speed mixer for 5 minutes, discharge. Dry, with less than 0.5% water. The dried material is melt extruded and granulated in a conical twin-screw extruder to obtain PPS pellets. Among them, the temperature of each zone of the twin-screw extruder is: 1st zone 295°C, 2nd zone 295°C, 3rd zone 305°C, head 315°C; screw speed 80rpm, length-to-diameter ratio L / D=30 / 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com