Preparation method of liquid fuel

A technology for liquid fuels and raw materials, applied in the field of coal chemical industry, can solve the problems of short operation cycle, low hydrogenation depth, and no relevant reports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

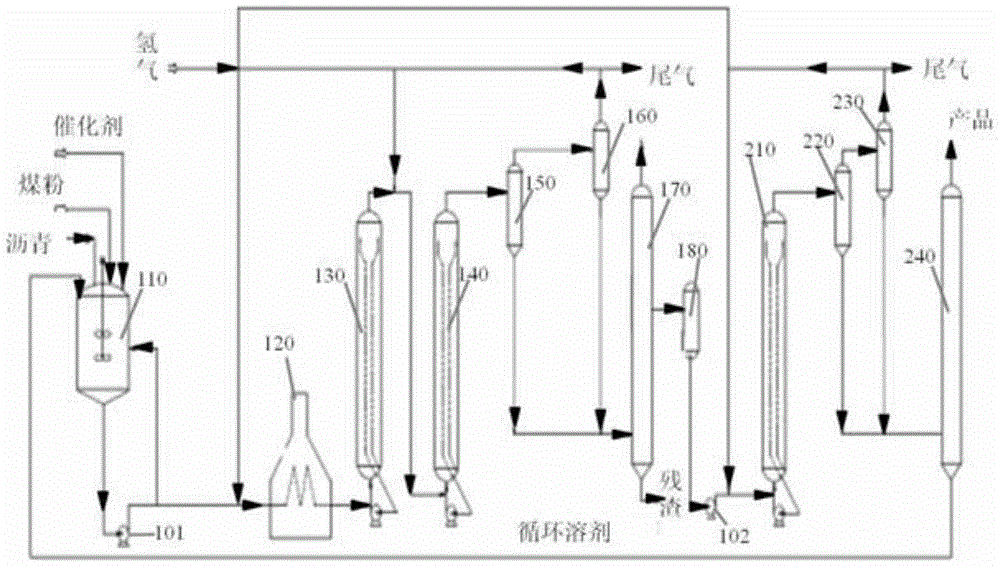

[0025] As described in the background art, the existing process for preparing liquid fuel from bitumen has the problems of high operational difficulty and low conversion rate of bitumen. In order to solve the above problems, the present invention provides a method for preparing liquid fuel, comprising the following steps: S1, mixing raw coal, bitumen and coal liquefaction circulating solvent to obtain a mixture; S2, making the above mixture under the action of a catalyst Liquefaction reaction, after the gas-liquid separation of the liquefaction reaction product, to obtain coal liquefied oil; and S3, the above-mentioned coal liquefied oil is subjected to catalytic hydrogenation reaction, and the liquid phase product of catalytic hydrogenation is subjected to fractional distillation to obtain liquid fuel and coal liquefaction circulating solvent . In the above preparation method provided by the present invention, the bitumen is mixed with coal for co-processing, undergoing lique...

Embodiment 1

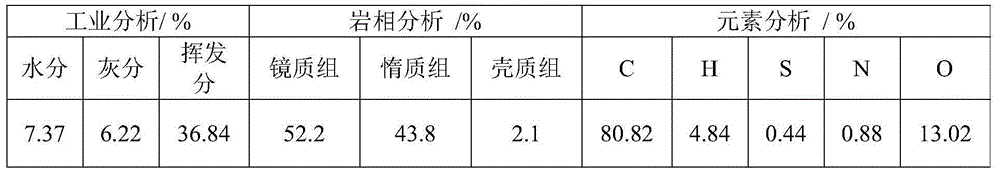

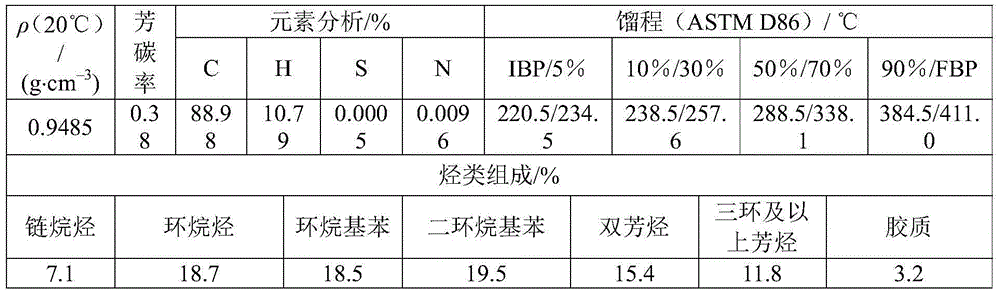

[0041] On the coal direct liquefaction continuous test device, the raw coal and the coal liquefaction circulating solvent are mixed in a coal slurry tank to obtain a coal slurry; then the coal slurry is mixed with coal tar pitch at 150°C to obtain an oil-coal slurry, in which the oil-coal The coal powder in the slurry accounts for 40% of the total weight of the oil-coal slurry, the amount of coal tar pitch added accounts for 10% of the total weight of the oil-coal slurry, and the viscosity of the obtained oil-coal slurry is less than 1000mpa.s (at 60°C). The basic properties of raw coal are shown in Table 1; the circulating solvent is distillate oil with a distillation range of 220-450°C for direct coal liquefaction, and its basic properties are shown in Table 2; coal tar pitch is obtained by reprocessing the product of coal dry distillation (coal tar). The basic properties obtained are listed in Table 3.

[0042] Add hydrated iron oxide catalyst in the prepared oil coal slurr...

Embodiment 2

[0046] On the coal direct liquefaction continuous test device, the raw coal and the coal liquefaction circulating solvent are mixed in a coal slurry tank, and then the coal slurry is mixed with coal tar pitch at 150°C to obtain an oil-coal slurry, wherein the coal powder in the oil-coal slurry Accounting for 40% of the total weight of the oil-coal slurry, the amount of coal tar pitch added accounts for 20% of the total weight of the oil-coal slurry, and the viscosity of the oil-coal slurry is less than 1000mpa.s (at 60°C). The basic properties of raw coal are shown in Table 1; the circulating solvent is distillate oil with a distillation range of 220-450°C for direct coal liquefaction, and its basic properties are shown in Table 2; coal tar pitch is obtained by reprocessing the product of coal dry distillation (coal tar). The basic properties obtained are listed in Table 3.

[0047] Add hydrated iron oxide catalyst in the prepared oil coal slurry, the addition amount of cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com