Method for improving yield of purple non-sulfur bacteria thallus 5-aminolevulinic acid

A technology of aminolevulinic acid yield and purple non-sulfur bacteria, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem of low yield of 5-aminolevulinic acid and the ability to degrade organic wastewater limited, hindering the process of resource utilization of 5-aminolevulinic acid, etc., to achieve the effects of easy promotion, increased yield, and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

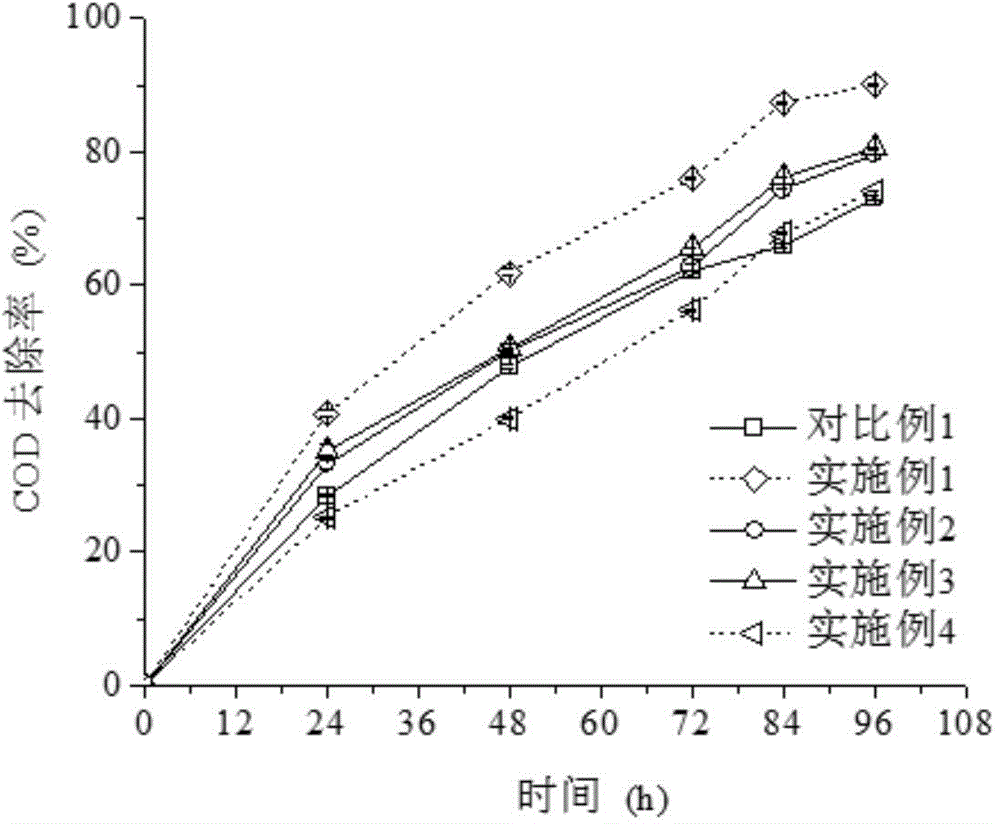

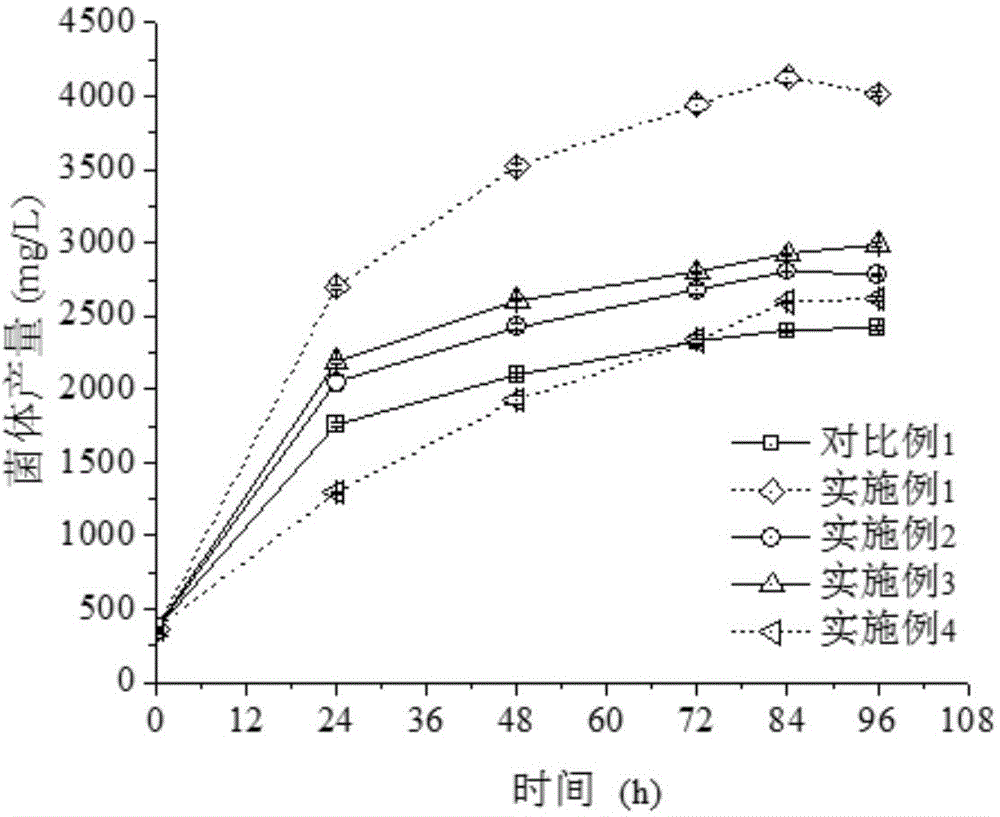

[0021] Specific embodiment one: this embodiment improves purple non-sulfur bacterial cell 5-aminolevulinic acid productive rate according to the following steps:

[0022] 1. Adjust the pH value of the organic wastewater to 6.5-7.5, and then add metal ions Fe to the organic wastewater 2+ , and then add purple non-sulfur bacteria to make the initial fermentation solution;

[0023] 2. Ferment the initial fermentation liquid in step 1 under the conditions of light intensity of 1000-3000 lux, dissolved oxygen concentration controlled at 0.5-1.0 mg / L, and temperature of 25-30°C to realize purple non-sulfur bacterial cell 5- Increased yield of aminolevulinic acid;

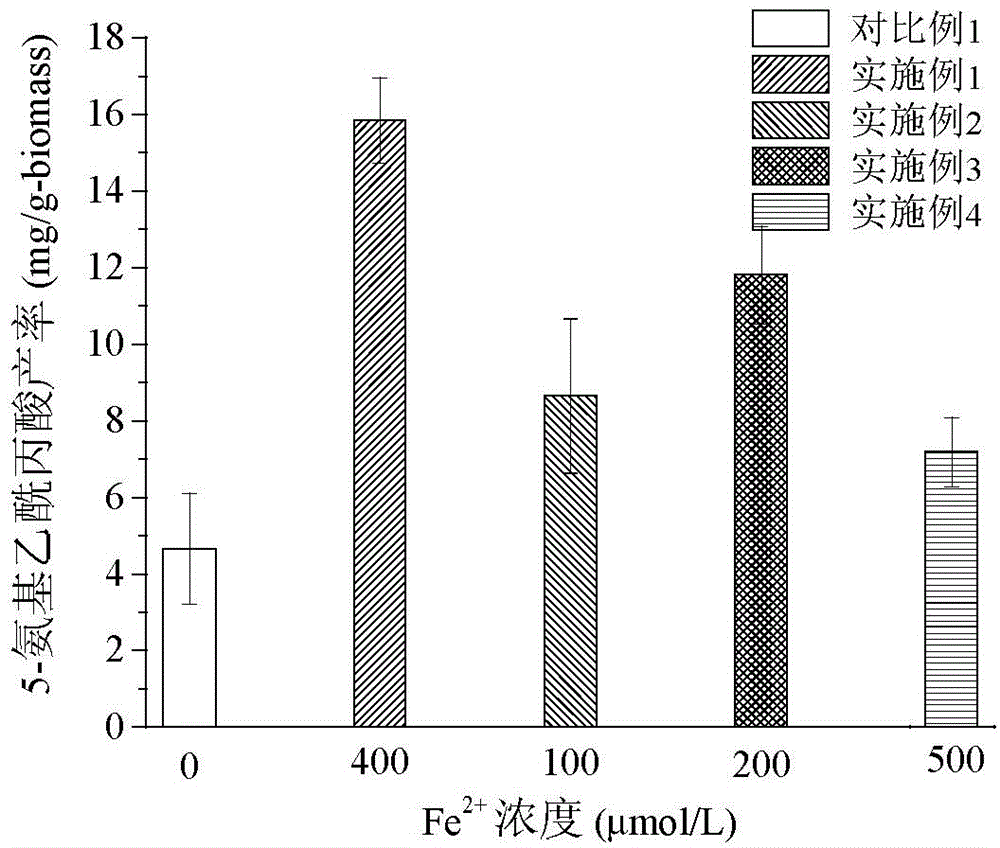

[0024] Wherein, the metal ion Fe in the initial fermentation liquid of step 1 2+ The concentration is 50μmol / L~600μmol / L;

[0025] Step 1 The COD content of the organic wastewater is 6000-10000 mg / L, the TN content is 400-800 mg / L, and the TP content is 20-60 mg / L.

[0026] The purple non-sulfur bacteria (PNSB) used i...

specific Embodiment approach 2

[0027] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the metal ion Fe in the initial liquid of step 1 fermentation 2+ The concentration is 100μmol / L~500μmol / L. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the metal ion Fe in the initial liquid of step 1 fermentation 2+ The concentration is 200μmol / L~450μmol / L. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com