a doped na + The preparation method of nano lithium titanate

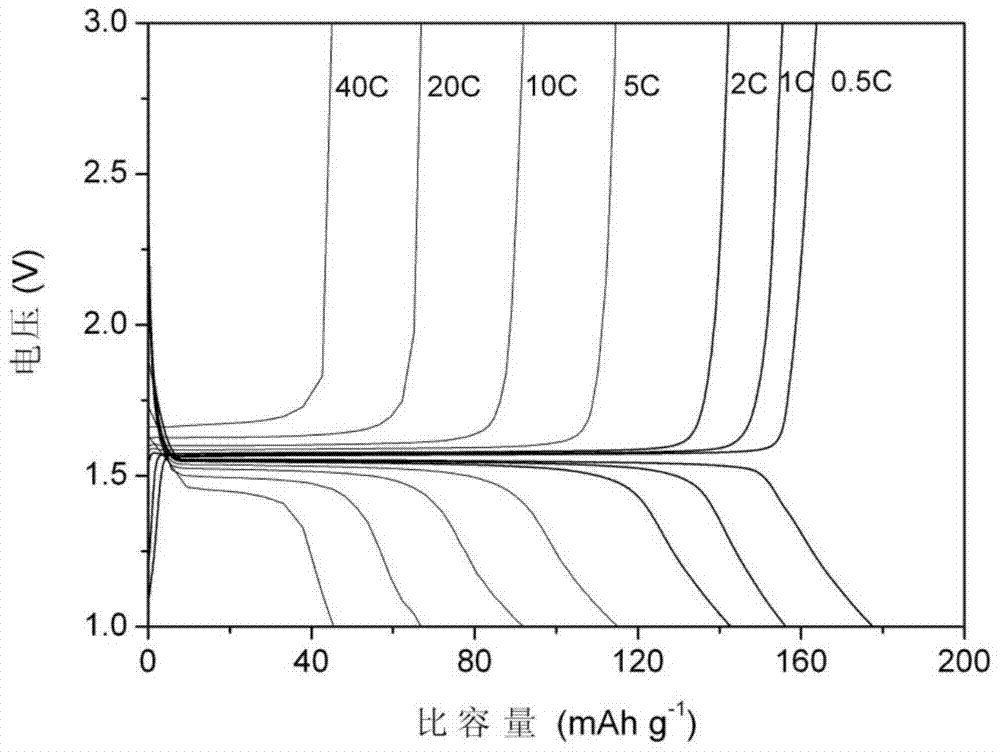

A technology of nano-lithium titanate and solution, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems affecting battery performance, poor conductivity, easy enrichment of electrons, etc., and achieve stable cycle performance, high charge-discharge specific capacity, and the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment relates to a doped Na + The preparation method of the nano-lithium titanate, specifically as follows:

[0038] Step 1, 2 mL of polyethylene glycol octylphenyl ether (chemically pure) and 2 mL of n-hexanol (analytical pure) are premixed to form a mixed solution, and then an appropriate amount of deionized water is added to form a 64 mL dissolving agent;

[0039] Step 2, the dissolving agent is magnetically stirred at room temperature until the solution is clear and uniform to obtain solution A;

[0040] Step 3, according to the molar ratio Li:Na=3.98:0.02, get 0.4969g lithium carbonate (analytical pure, pre-ground into fine powder) and 0.00358g sodium carbonate (analytical pure) to mix, add 2mL deionized water and shake up, get Solution B;

[0041]Step 4: Pour solution B into a uniformly mixed solution (solution A) of polyethylene glycol octylphenyl ether and n-hexanol, and magnetically stir in a constant temperature water bath for 20 minutes to obtain ...

Embodiment 2

[0048] This embodiment relates to a doped Na + The preparation method of the nano-lithium titanate, specifically as follows:

[0049] Step 1, 4 mL of polyethylene glycol octylphenyl ether (chemically pure) and 2 mL of n-hexanol (analytical pure) are premixed to form a mixed solution, and then an appropriate amount of deionized water is added to form a 66 mL dissolving agent;

[0050] Step 2, the dissolving agent is magnetically stirred at room temperature until the solution is clear and uniform to obtain solution A;

[0051] Step 3, according to the molar ratio Li:Na=3.95:0.05, get 0.4932g lithium carbonate (analytical pure, pre-ground into fine powder) and 0.00896g sodium carbonate (analytical pure) to mix, add 2mL deionized water and shake up, get Solution B;

[0052] Step 4: Pour solution B into a homogeneously mixed solution of polyethylene glycol octylphenyl ether and n-hexanol, and magnetically stir in a constant temperature water bath for 20 minutes to obtain a unifor...

Embodiment 3

[0059] This embodiment relates to a doped Na + The preparation method of the nano-lithium titanate, specifically as follows:

[0060] Step 1, 6 mL of polyethylene glycol octylphenyl ether (chemically pure) and 2 mL of n-hexanol (analytical pure) are premixed to form a mixed solution, and then an appropriate amount of deionized water is added to form a 68 mL dissolving agent;

[0061] Step 2, the dissolving agent is magnetically stirred at room temperature until the solution is clear and uniform to obtain solution A;

[0062] Step 3, according to the molar ratio Li:Na=3.92:0.08, get 0.4894g lithium carbonate (analytical pure, pre-ground into fine powder) and 0.0143g sodium carbonate (analytical pure) to mix, add 2mL deionized water and shake up, get Solution B;

[0063] Step 4: Pour solution B into a homogeneously mixed solution of polyethylene glycol octylphenyl ether and n-hexanol, and magnetically stir in a constant temperature water bath for 20 minutes to obtain a uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com