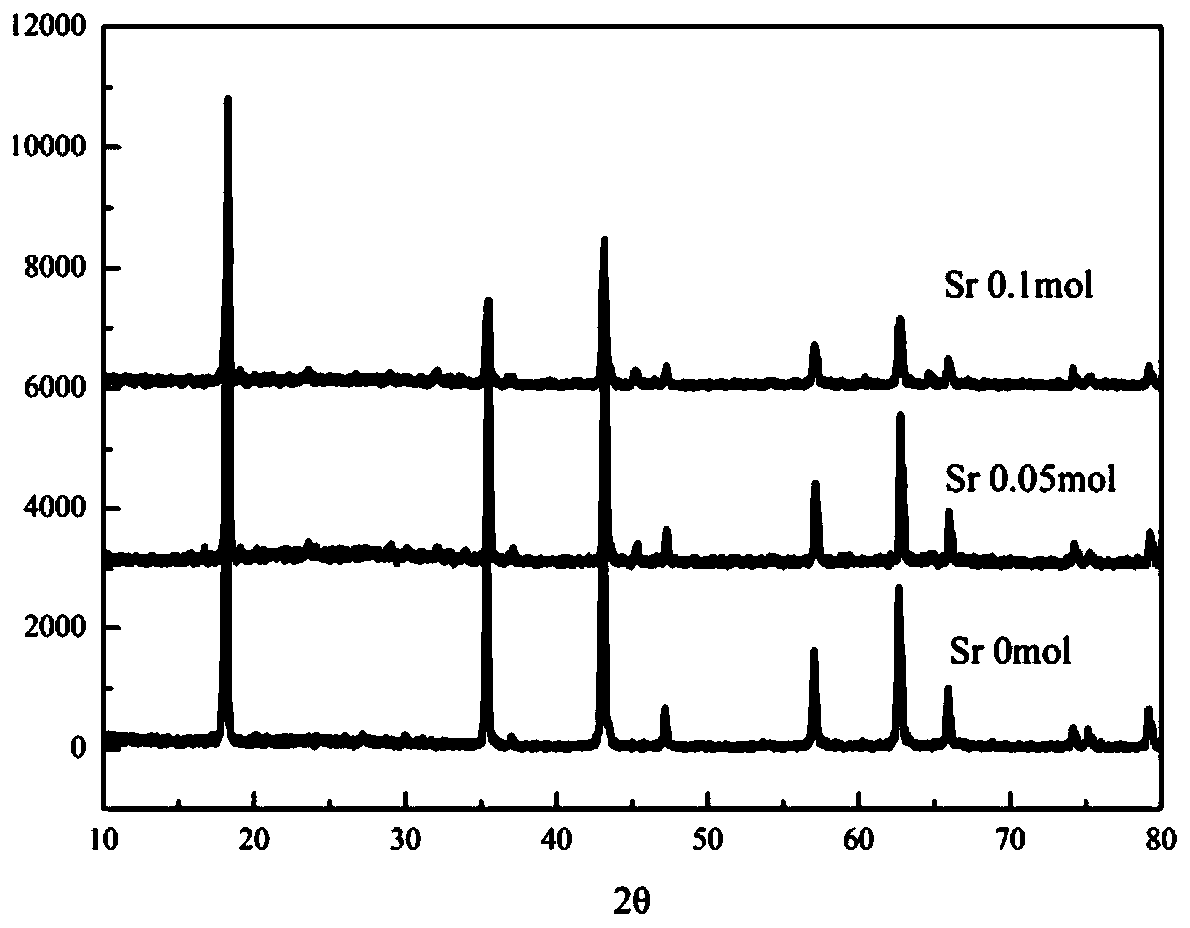

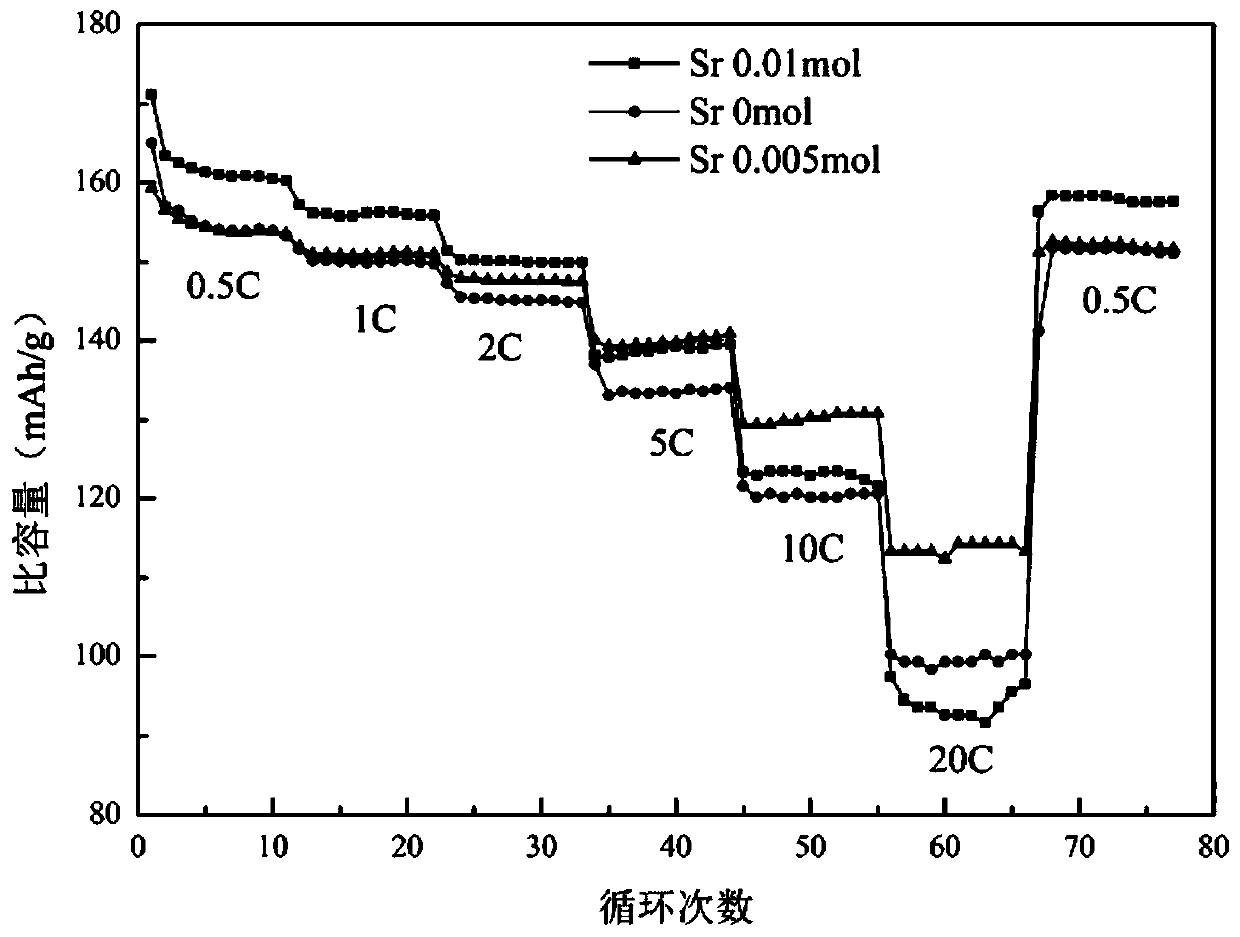

A kind of preparation method of enriching strontium element on the surface of nanometer lithium titanate

A nano-lithium titanate, enrichment technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complexation speed influence, metal ion distribution imbalance, etc., to improve the mixing Effects of uniformity, mitigation of particle agglomeration, high charge-discharge capacity, and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 3.4 mL of HNO to 170.16 mL of absolute ethanol 3As a hydrolysis inhibitor of tetrabutyl titanate, solution A was prepared; according to the molar ratio Li+Sr:Ti=4.2:5, wherein Li:Sr=4.15:0.05, 8.508g tetra-n-butyl titanate was put into solution A Esters (analytical pure) and 0.766g lithium carbonate (analytical pure, pre-ground into fine powder) and 0.0529g Sr (NO3) 2 (analytical pure), magnetically stirred until completely dissolved and in a clear state; Acetic acid: citric acid = 1:2, weigh 13.443g of ethylenediaminetetraacetic acid and 17.677g of citric acid, drop 10mL of distilled water to pre-mix, then add 35.4mL of ammonia water to dissolve, and prepare solution B. Mix solution A and solution B, adjust the pH of the mixed solution to 10 with ammonia water, and continue stirring until the mixed solution becomes clear as a sol. Continue heating and stirring at 100°C for 3 hours. After the sol becomes a transparent gel, put it in a blast oven at 240°C and dry it...

Embodiment 2

[0032] Mix 85.08mL of absolute ethanol with 8.51mL of deionized water according to the volume ratio of 1:0.1, add 8.51mL of hydrochloric acid as the hydrolysis inhibitor of the subsequent reactant, and obtain solution A; according to the molar ratio Li+Sr:Ti=4.3: 5 where Li:Sr=4.2:0.1, put 8.508g tetra-n-butyl titanate (analytical pure) and 1.386g lithium acetate (analytical pure) and 0.1028g strontium acetate (analytical pure) into solution A, magnetically stir until complete Dissolved in a clear state; according to the molar ratio of EDTA:citric acid=1:1.5, weigh 6.795g EDTA and 6.701g citric acid, drop 5mL distilled water for pre-mixing, then add 15.21mL ammonia water to dissolve, With solution B. Mix solution A and solution B, adjust the pH of the mixed solution to 7 with ammonia water, and continue stirring until the mixed solution becomes clear as a sol. Continue heating and stirring at 80°C for 4 hours. After the sol becomes a transparent gel, put it in a blast oven at...

Embodiment 3

[0034] Mix 112.18mL of absolute ethanol with 22.44mL of deionized water according to the volume ratio of 1:0.2, add 22.44mL of acetic acid as the hydrolysis inhibitor of the subsequent reactant, and obtain solution A; according to the molar ratio Li+Sr:Ti=4.0: 5 where Li:Sr=3.93:0.07, put 7.105g tetraisopropyl titanate (analytical pure) and 1.356g lithium nitrate (analytical pure) and 0.0741g strontium nitrate (analytical pure) into solution A, magnetically stir until complete Dissolved in a clear state; according to the molar ratio of ethylenediaminetetraacetic acid: citric acid = 1:1, weigh 13.151g ethylenediaminetetraacetic acid and 8.646g citric acid, drop 10mL distilled water for pre-mixing, then add 24.24mL ammonia water to dissolve, With solution B. Mix solution A and solution B, adjust the pH of the mixed solution to 8 with ammonia water, and continue stirring until the mixed solution becomes clear as a sol. Continue heating and stirring at 60°C for 5 hours. After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com