Method of treating polyester textile

A technology for textiles and polyester fabrics, used in textiles and papermaking, fiber processing, biochemical fiber processing, etc., can solve problems such as fiber material loss, improve antistatic properties, reduce pellet formation, and enhance efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

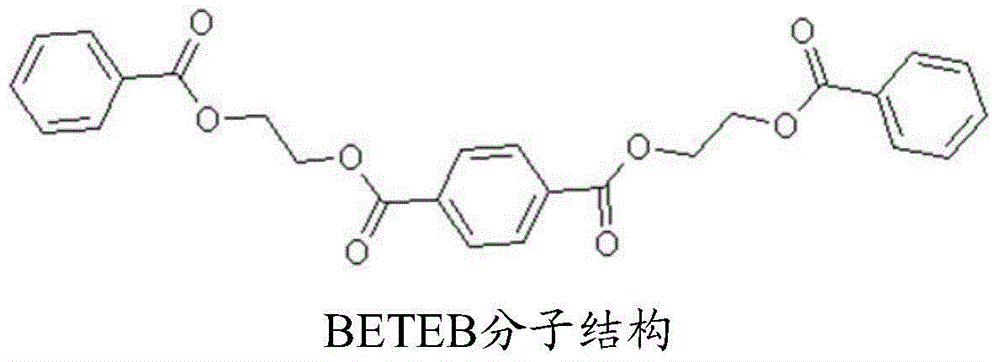

[0197] Example 1: BETEB-agar plate is used to evaluate the cutinase activity

[0198] BETEB is hydrolyzed by cutinase into a more soluble reagent. Therefore, after enzymatic hydrolysis, there is a transparent area on the plate where the mixture of agar and BETEB is poured.

[0199]

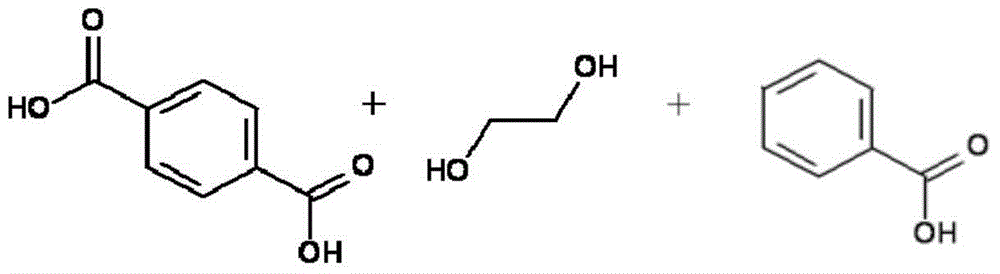

[0200] Hydrolysis of BETEB will produce

[0201]

[0202] The cutinase activity is measured by the following process:

[0203] a) BETEB solution formulation: 5ml of 100% ethanol was added to a glass bottle with a stopper, 20mg BETEB was added to the ethanol and then the bottle was placed in a 60°C water bath to dissolve the BETEB.

[0204] b) Prepare a 1.5% agar solution by adding 0.75g of agar to 45ml of Tris-HCl buffer (25mM, pH 7.0), and then placing the dryer in a microwave oven and heating twice for 30 seconds to dissolve the agar .

[0205] c) Cool the agar solution to 60°C and mix with the BETEB solution prepared in step a. The mixture was poured into a petri dish.

[0206] d) Dig small holes in the...

example 2

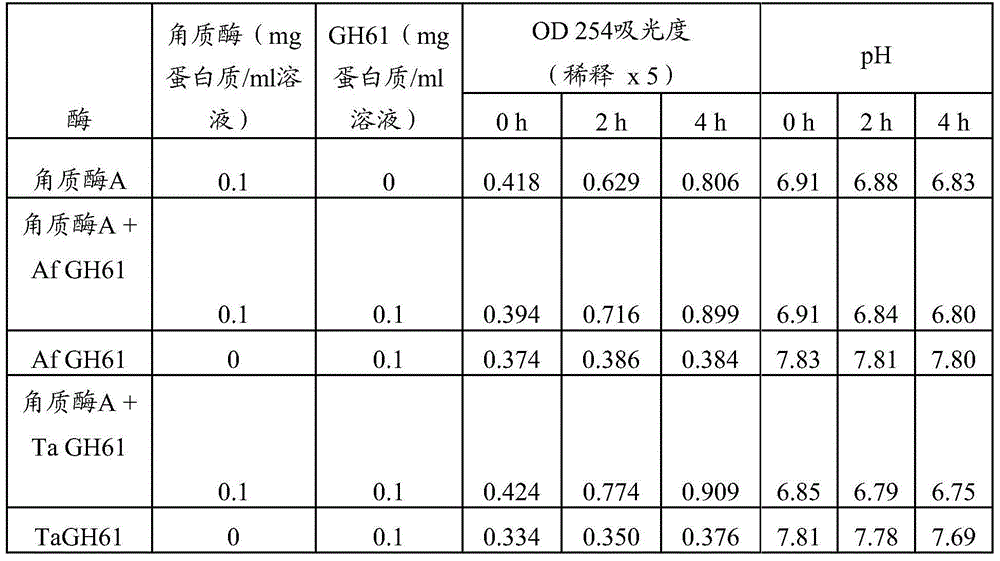

[0209] Example 2: Cutinase A and GH61 are used for PET treatment.

[0210] In this example, two GH61s, Af GH61 and Ta GH61, were used in combination with Cutinase A to hydrolyze the PET spots in a 1.5 ml Epdorf tube.

[0211] The PET fabric was cut into small pieces of 0.5 cm diameter, 0.005 g / piece, and two pieces were added to each Epdorf tube. Britten-Robinson buffer (4mM, pH 8) and 1% Triton X 100 were placed in a thermomixer at 70°C for 5 minutes to preheat. After preheating, add cutinase and GH61 to the tube to get a total volume of 1ml, where the final concentration of Triton X 100 is 0.2g / l, and the final concentration of cutinase and GH61 in the solution is as shown in the table Shown in 1. Test the absorbance and pH of OD 254 as described in the materials and methods section, and directly show the data at 0 hours in Table 1. Place these tubes in a thermomixer to start the reaction at 1000 rpm and 70°C. After the reaction continued for a certain period of time as speci...

example 3

[0218] Example 3: Cutinase B and GH61 are used for PET treatment.

[0219] In this example, two kinds of GH61 were used in combination with cutinase B to hydrolyze the PET fabric in the Epdorf tube. The treatment scheme is the same as that described in Example 2.

[0220] Table 2. Results of PET treatment with Cutinase B and GH61 (70°C, pH 7.0, 1000 rpm, 0-4 hours)

[0221]

[0222] Note: The average value of three replicate samples for each enzyme combination in Table 2.

[0223] As can be seen from Table 2, at 2 hours, the addition of Af GH61 or Ta GH61 to Cutinase B increased the absorbance at 254 nm by 0.057 and 0.028, respectively, and at 4 hours, the absorbance increased by 0.082 and 0.058, respectively. After 2 to 4 hours, there was also a slight increase in pH changes before and after the reaction. In conclusion, GH61 showed a promoting effect on cutinase B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com