Preparation process of dipyridamole-loaded polyurethane anticoagulant material

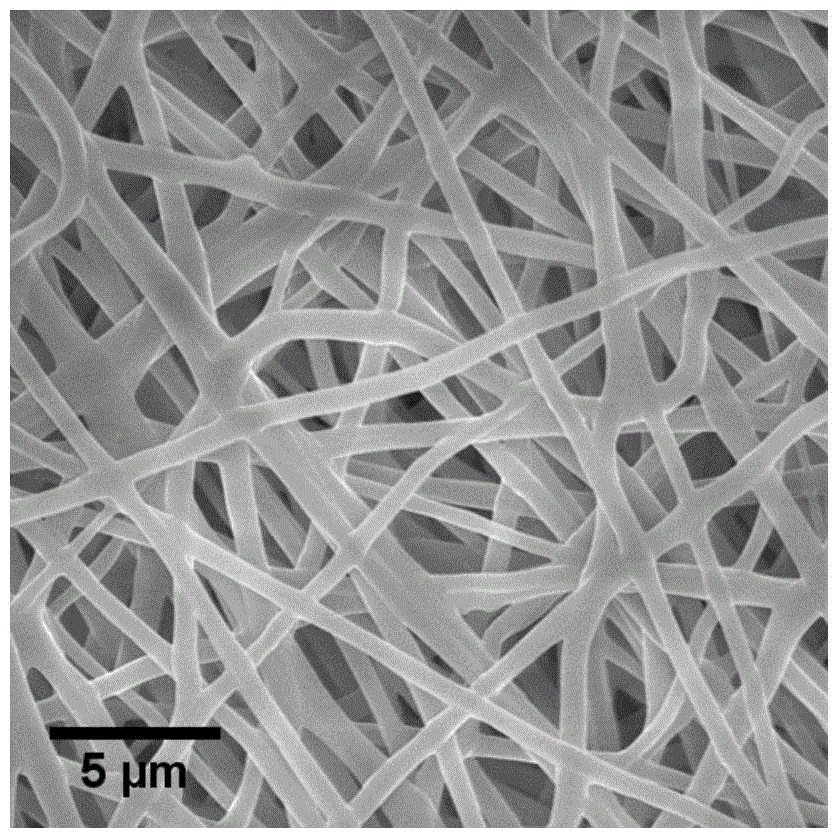

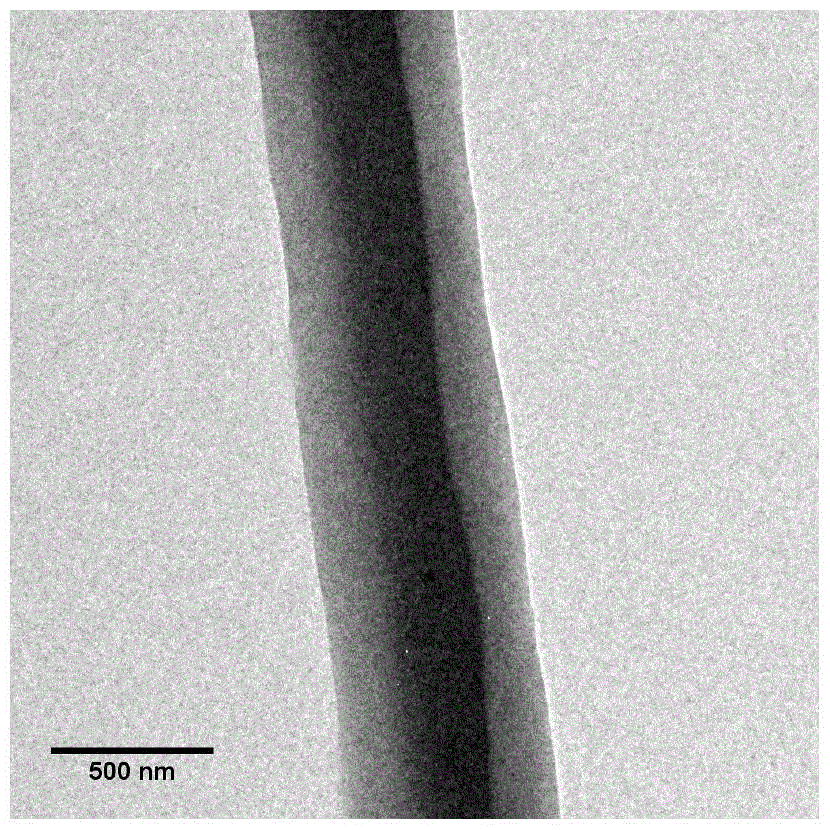

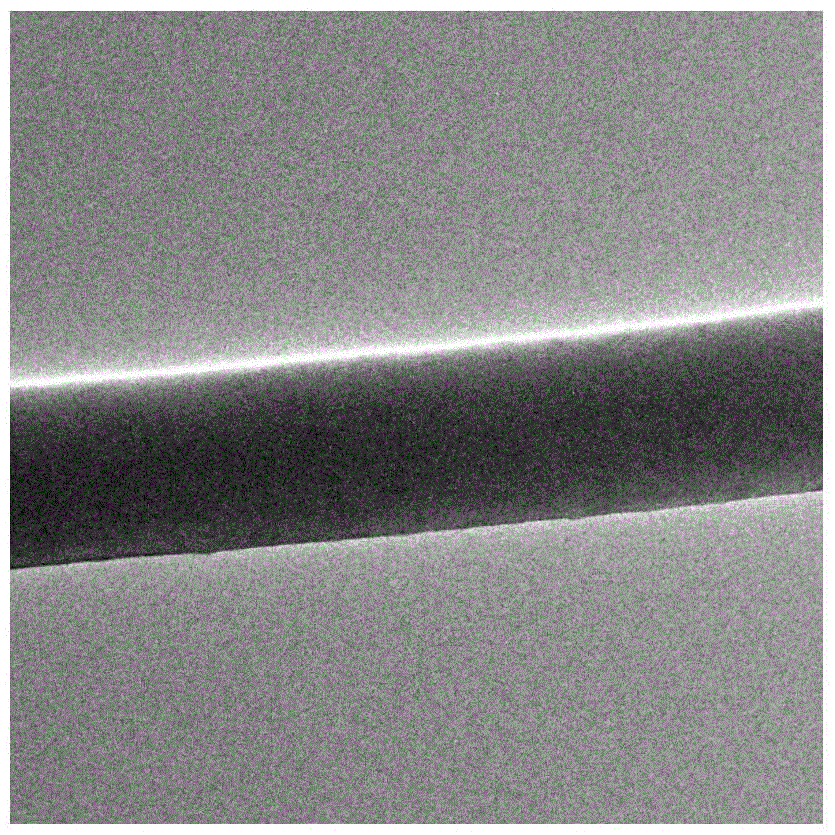

A technology for the preparation of pyridamole polyurethane, which is applied in the field of dipyridamole-loaded polyurethane anticoagulant materials and its preparation technology, can solve the problems of limited electrospinning process and complex technical parameters of coaxial electrospinning, and achieve Improve the success rate of transplantation, avoid acute thrombosis and intimal hyperplasia, and have good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Prepare the external fluid: dissolve 1.5g of polyurethane in 10ml of a mixed solution of tetrahydrofuran and N,N-dimethylformamide with a volume ratio of 5:5, and stir overnight;

[0040] 2) Prepare internal fluid: dissolve 30mg dipyridamole and 1.1g polycaprolactone (molecular weight 8000-10000) in 4.4g chloroform, and shake for 10 minutes;

[0041] 3) Coaxial electrospinning: inner fluid flow rate: 0.1ml / h, outer fluid flow rate: 0.7ml / h; coaxial spinning nozzle outer tube diameter 1.54mm, inner tube diameter 0.51mm; voltage: 15 ~ 20KV, ground The thread is added to the blood vessel mold, the distance between the coaxial spinning nozzle and the blood vessel mold is kept at 20 cm, and the speed of the blood vessel mold is 100 rpm; the temperature in the electrospinning box is kept at 40 ° C, and the humidity is 30% to 40%. Electrospinning time is 2 to 3 hours;

[0042] 4) After the electrospinning, the artificial blood vessel was removed from the mold, and dried in...

Embodiment 2

[0044] 1) Prepare the external fluid: dissolve 1g of polyurethane in 10ml of a mixed solution of tetrahydrofuran and N,N-dimethylformamide with a volume ratio of 7:3, and stir overnight;

[0045] 2) Prepare internal fluid: dissolve 60mg of dipyridamole and 1.1g of polyethylene glycol 6000 in 4.4g of chloroform, and shake for 10 minutes;

[0046] 3) Coaxial electrospinning: inner fluid flow rate: 0.1ml / h, outer fluid flow rate: 0.7ml / h; coaxial spinning nozzle outer tube diameter 1.54mm, inner tube diameter 0.51mm; voltage: 15 ~ 20KV, ground The thread is added to the blood vessel mold, the distance between the coaxial spinning nozzle and the blood vessel mold is kept at 20 cm, and the speed of the blood vessel mold is 100 rpm; the temperature in the electrospinning box is kept at 40 ° C, and the humidity is 30% to 40%. Electrospinning time is 2 to 3 hours;

[0047] 4) After the electrospinning, the artificial blood vessel was removed from the mold, and dried in vacuum at 80° C....

Embodiment 3

[0049] 1) Prepare the external fluid: dissolve 1.2g of polyurethane in 10ml of a mixed solution of tetrahydrofuran and N,N-dimethylformamide with a volume ratio of 3:7, and stir overnight;

[0050] 2) Prepare internal fluid: dissolve 80mg of dipyridamole and 2.0g of polyethylene glycol 6000 in 4.4g of chloroform, and shake for 10 minutes;

[0051] 3) Coaxial electrospinning: inner fluid flow rate: 0.2ml / h, outer fluid flow rate: 1.0ml / h; coaxial spinning nozzle outer tube diameter 1.54mm, inner tube diameter 0.51mm; voltage: 15 ~ 20KV, ground The thread is added to the blood vessel mold, the distance between the coaxial spinning nozzle and the blood vessel mold is kept at 20 cm, and the speed of the blood vessel mold is 100 rpm; the temperature in the electrospinning box is kept at 40 ° C, and the humidity is 30% to 40%. Electrospinning time is 2 to 3 hours;

[0052] 4) After the electrospinning, the artificial blood vessel was removed from the mold, and dried in vacuum at 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com