Heterogeneous p-n knot nano composite material and preparation method and application thereof

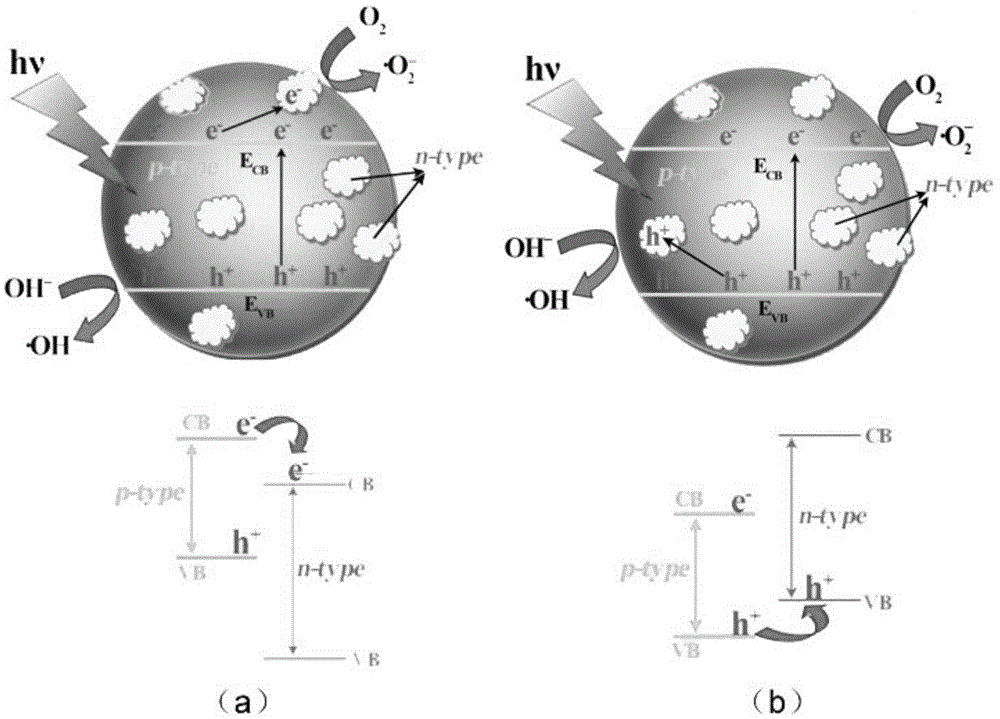

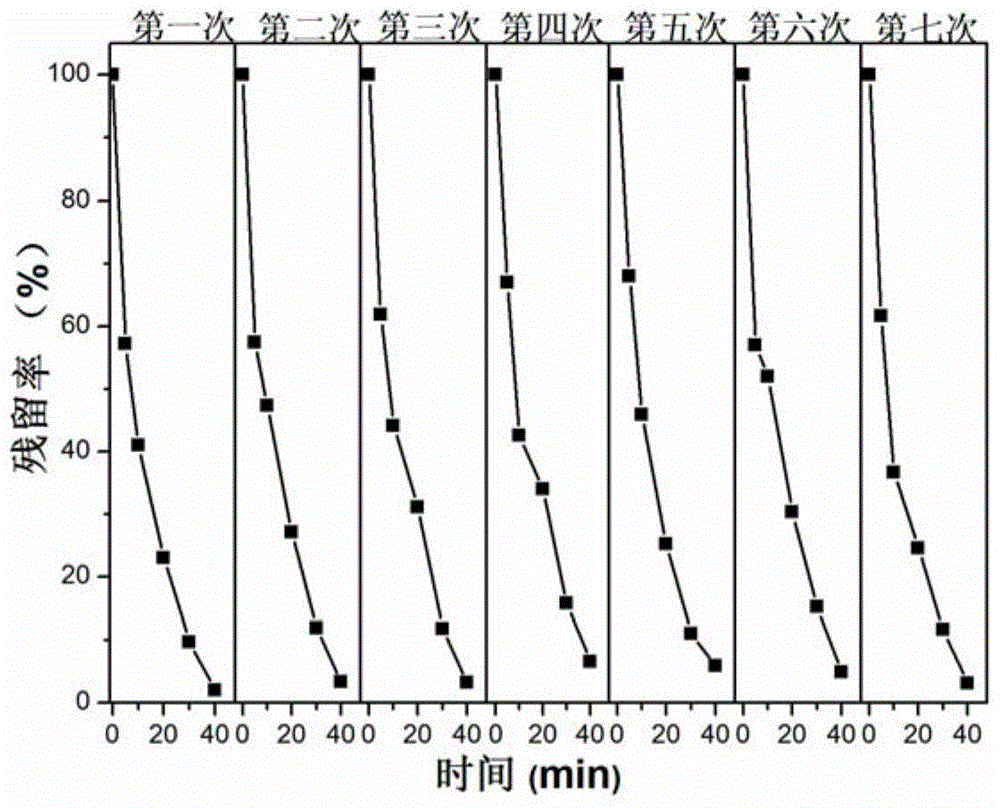

A nanocomposite material and composite material technology are applied in the field of heterogeneous p-n junction nanocomposite materials and their preparation, which can solve problems such as low electron-hole separation efficiency, avoid photocorrosion, improve photocatalytic efficiency and utilize solar energy. rate, the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

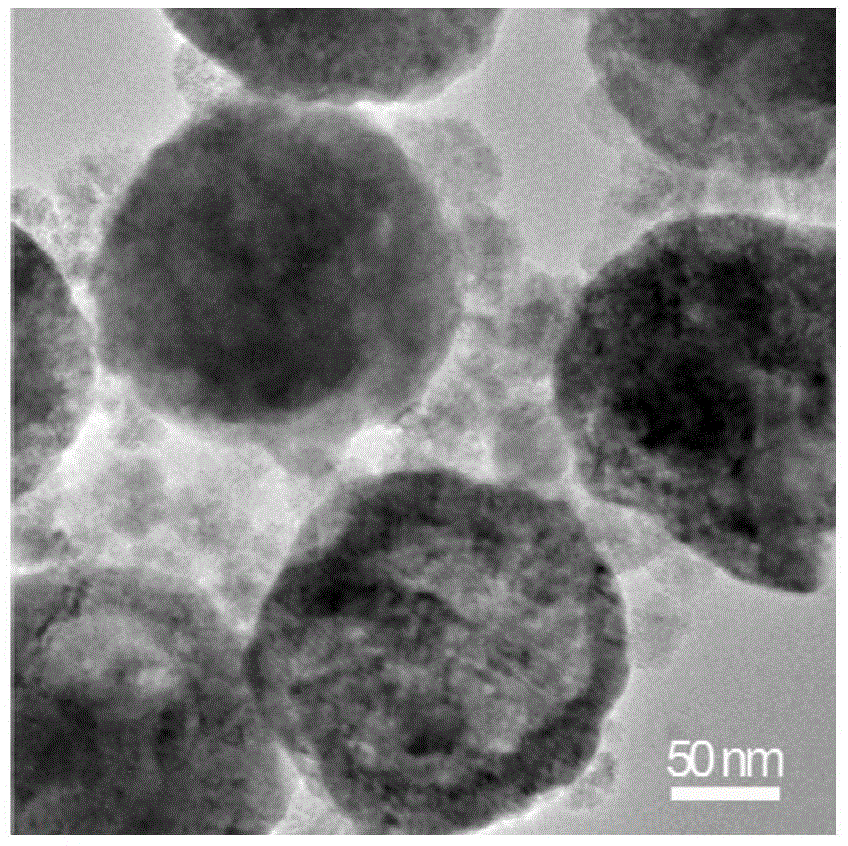

[0041] With cuprous oxide nanospheres as the core, the surface is modified with nanoscale island-shaped titanium dioxide heterogeneous p-n junctions, and the preparation process of Ti:Cu molar ratio is 5% is as follows:

[0042] 1. Mix 0.2g polyvinylpyrrolidone k30, 34mg CuCl 2 2H 2 O was dissolved in 100mL deionized water, under the action of magnetic stirring, 3.6mL of 8g / L sodium hydroxide aqueous solution was added dropwise to the above solution at a rate of one drop per second, stirred for 5min, and then 4mL of 17.6g / L L ascorbic acid aqueous solution was added dropwise to the above solution at a rate of one drop every three seconds, stirred for 5 minutes and then centrifuged. During this process, the cuprous oxide nanoparticles obtained at 20°C were spherical, and at 35°C they were cubes with a size of about 100nm.

[0043] 2. Wash the cuprous oxide nanoparticles obtained in step 1 alternately with deionized water and absolute ethanol for 5 times, and wash with deionize...

Embodiment 2

[0052] With cuprous sulfide nanospheres as the core, the surface is modified with nanoscale island-shaped titanium dioxide heterogeneous p-n junctions, and the preparation process of Ti:Cu molar ratio is 10% is as follows:

[0053] 1. Mix 0.2g polyvinylpyrrolidone k30, 34mg CuCl 2 2H 2 O was dissolved in 100mL deionized water, under the action of magnetic stirring, 3.6mL of 8g / L sodium hydroxide aqueous solution was added dropwise to the above solution at a rate of one drop per second, stirred for 5min, and then 4mL of 17.6g / L L ascorbic acid aqueous solution was added dropwise to the above solution at a rate of one drop every three seconds, stirred for 5 minutes and then centrifuged. During this process, the cuprous oxide nanoparticles obtained at 20°C were spherical, and at 35°C they were cubes, with a size of about 100nm.

[0054] 2. Alternately wash the cuprous oxide nanoparticles obtained in 1 with deionized water and absolute ethanol for 3 times, and then ultrasonically...

Embodiment 3

[0064] The preparation process of the heterogeneous p-n junction with cadmium sulfide as the core and surface modified zinc oxide, and the molar ratio of Zn:Cd is 30% is as follows:

[0065] 1. First, dissolve 1.5mmol of cadmium acetate in 40mL of deionized water in a water bath at 80°C to make a cadmium acetate solution. Then, under magnetic stirring, add 10-20mL of sodium sulfide aqueous solution with a concentration of 15.6g / L Add it dropwise into cadmium acetate solution, react for 30 minutes, and centrifuge to obtain cadmium sulfide nanoparticles.

[0066] 2. The cadmium sulfide nanoparticles obtained in step 1 were alternately washed 5 times with deionized water and absolute ethanol, and the washed cadmium sulfide nanoparticles were immediately dispersed in 10 mL of absolute ethanol, and ultrasonically dispersed for 10 minutes to obtain solution A.

[0067] 3. Dissolve 0.219g of zinc acetate in 10ml of deionized water to make solution B. According to the loading capacity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com