Active hydrocracking proppant and preparation method thereof

A technology for hydrocracking and hydrogenation activity, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. It has problems such as catalytic activity and low mechanical strength, and achieves the effect of improving the overall effect, improving the space utilization rate and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

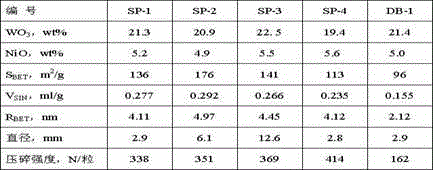

Embodiment 1

[0034] Amorphous silica-alumina dry rubber powder, macroporous pseudo-boehmite dry rubber powder and nanoscale small-pore pseudo-boehmite dry rubber powder with a mass ratio of 2:1:2 are placed in a roller compactor, and auxiliary Extrusion agent, sage powder, etc., the concentration of adding is 6.0gHNO 3 / 100mL and 10.0g acetic acid / 100mL mixed acid solution for peptization, extruded into a cylindrical shape with a diameter of 3mm, dried at 80°C for 30min, and then cut into balls with a spherical mold, and dried at 120°C for 6 hours to prepare the proppant carrier. Then impregnate the W-Ni solution in a supersaturated manner, separate the solid from the liquid, dry at 120°C for 4 hours, and bake at 500°C for 3 hours to prepare the finished proppant. The number is SP-1.

Embodiment 2

[0036] The preparation method is the same as in Example 1, except that the mass ratio of amorphous silica-alumina dry rubber powder, macroporous pseudo-boehmite dry rubber powder and nanoscale small-pore pseudo-boehmite dry rubber powder is 1:2: 2. Extrude the rod with a diameter of 6 mm to obtain a finished proppant product numbered SP-2.

Embodiment 3

[0038] The preparation method is the same as that in Example 1, except that the dried spherical proppant carrier is subjected to hydrothermal treatment at 600°C and steam pressure of 0.2 MPa for 60 minutes to load hydrogenation active components to obtain the finished proppant product numbered SP-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Infrared acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com