A kind of preparation method of catalytic cracking auxiliary agent

A catalytic cracking aid, silicon tetrachloride technology, which is applied in the fields of hydrocarbon cracking to hydrocarbon production, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of large amount of template agent polluting the environment, difficult synthesis, etc., and achieve high production efficiency , The effect of stable product performance and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In the method for preparing catalytic cracking propylene additives provided by the present invention, NaZSM-5 molecular sieves are continuously introduced into the gas phase superstable reactor, so that the NaZSM-5 molecular sieves generally move continuously from the molecular sieve inlet without carrier gas delivery Go to the molecular sieve outlet, and contact with the silicon tetrachloride gas in the gas-phase ultra-stable reactor to carry out the ultra-stable reaction. Simultaneously, silicon tetrachloride was continuously introduced into the reactor.

[0030] In the method for preparing catalytic cracking propylene additive provided by the present invention, silicon tetrachloride can be introduced in the reactor in liquid phase and then vaporized in the reactor and reacted with NaZSM-5 molecular sieve, but in order to make the reaction uniform, preferably tetrachloride Silicon is vaporized and introduced into the gas-phase ultrastable reactor. Introduce NaZSM-5 m...

Embodiment approach

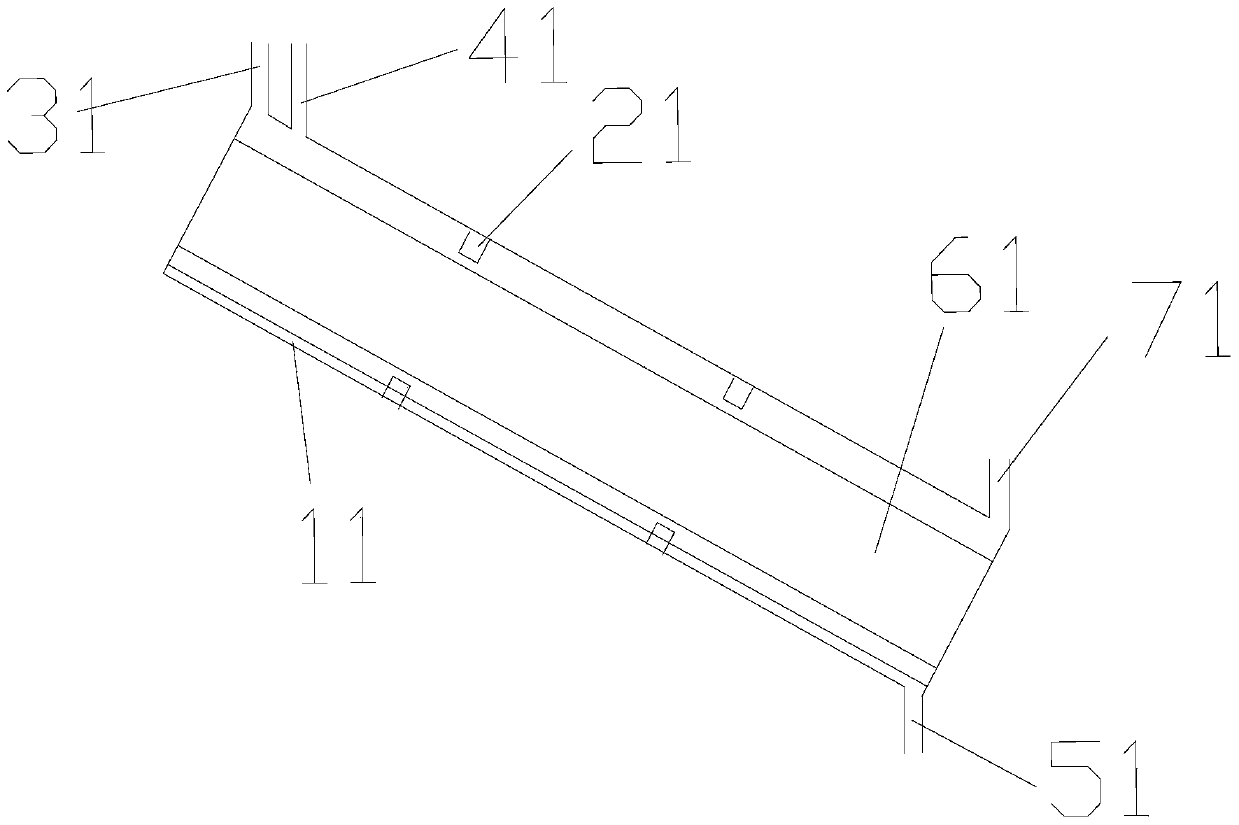

[0042] According to the second specific embodiment of the method for preparing catalytic cracking propylene auxiliary agent provided by the present invention, a kind of gas phase superstable reactor such as image 3 As shown, the gas phase ultra-stable reactor includes: a reactor tube body, a reactor flight plate 11, a baffle plate 21, a molecular sieve inlet 31, a gas phase silicon tetrachloride inlet 41, a molecular sieve outlet 51, an inner casing 61 and a gas outlet 71 , the reactor may also include a tube rotation drive mechanism (not shown). Silicon tetrachloride and NaZSM-5 molecular sieve are respectively introduced in the gap between sleeve pipe 61 and gas phase superstable reactor tube wall through silicon tetrachloride inlet 14 and molecular sieve inlet 31, and contact reaction, and wherein copy plate 11 can make tube The NaZSM-5 molecular sieve in the body is turned over, which is beneficial to the mixing of the NaZSM-5 molecular sieve and silicon tetrachloride, an...

Embodiment 1

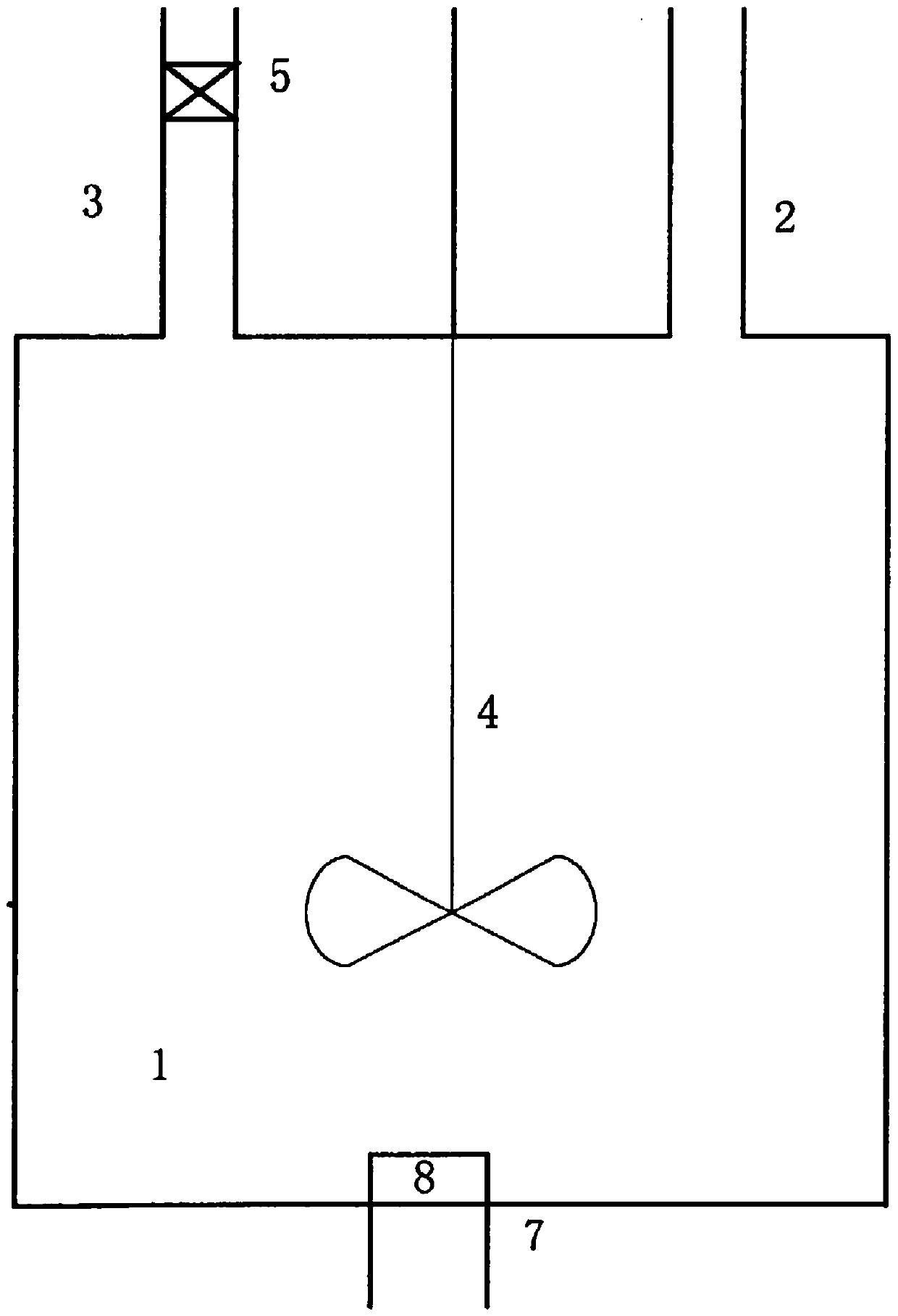

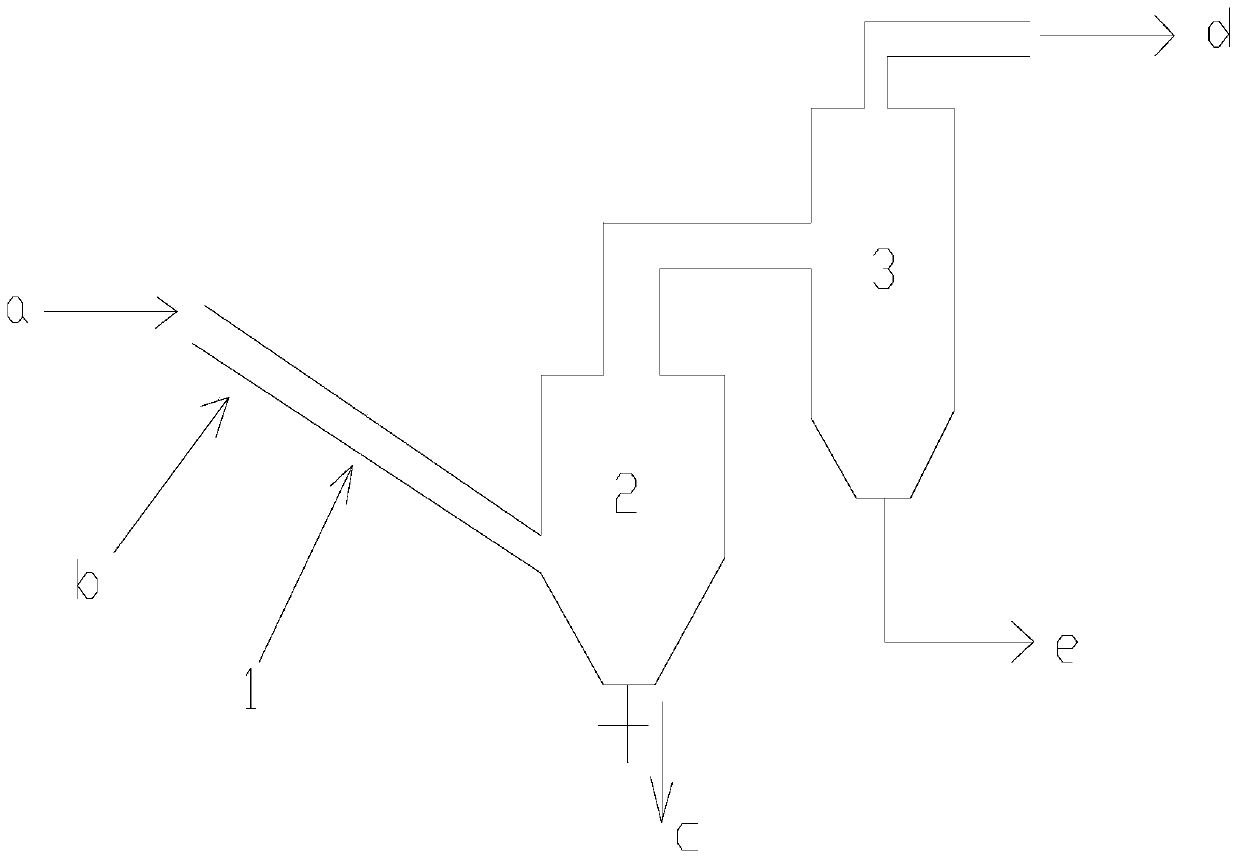

[0066] Made of industrial grade stainless steel with a thickness of 3mm NiCr18Ti figure 2 In the molecular sieve gas-phase silicon replenishment equipment shown, the upper part of the gas-solid separator 2 is cylindrical with a diameter of 6 meters and a height of 14 meters, and the lower part is conical with an opening with a cone angle of 45°, and a valve is provided at the opening , the outlet is located at a position 1 meter away from the top of the gas-solid separator, and the absorption tower 3 is filled with an aqueous sodium hydroxide solution with a concentration of 10 mol / liter. The absorption tower 3 and the gas-solid separator 2 are connected by a conduit, and the conduit goes deep into the Sodium hydroxide aqueous solution.

[0067] Reactor 1 is a tubular reactor, such as Figure 5 As shown, the total length of the pipe body is 80 meters, and the diameter of the pipe body is 0.8 meters. The pipe body of the reactor is made into a ring. The reactor includes an up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com