Flaky gamma-Al2O3 nanometer crystal and preparation method thereof

A nano-grain and flaky technology, which is applied in the field of flaky γ-Al2O3 nano-grain and its preparation, can solve the problems of low reactivity, small specific surface area of alumina, and few applications, and achieve cheap raw materials and simple preparation process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

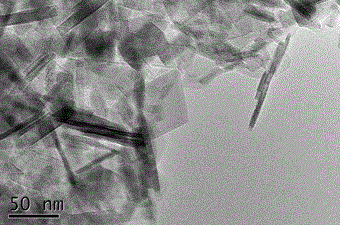

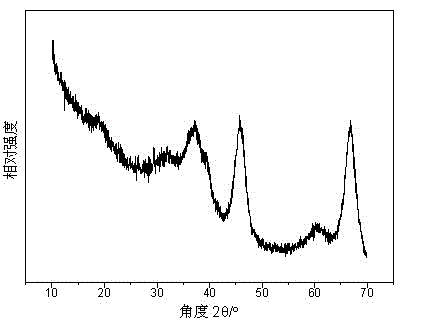

[0025] Prepare 10ml of 0.2mol / L aluminum nitrate solution and 30ml of 0.2mol / L sodium hydroxide solution, then mix and stir the sodium hydroxide solution and aluminum nitrate solution under 0.5KW / L ultrasonic and vigorous stirring conditions uniform. The mixture was kept airtight under hydrothermal condition at 190°C for 24 hours. Then cooled to room temperature, the product was separated and washed several times with distilled water to remove the impurity ions contained in it. After drying, it was calcined at 550°C for 7 hours to obtain flaky γ-Al 2 o 3 The nano crystal grains have a length of 10-26nm and a thickness of 5-8nm. The alumina nanoparticles are characterized by powder X-ray diffraction as γ-Al 2 o 3 , the specific surface area is 167m 2 / g.

Embodiment 2

[0027] Prepare 10ml of 0.2mol / L aluminum nitrate solution and 35ml of 0.2mol / L lithium hydroxide solution, and then mix the sodium hydroxide solution with the aluminum nitrate solution under 0.5KW / L ultrasound and stirring and stir evenly . The mixture was kept closed under hydrothermal condition at 200°C for 16 hours. Then cooled to room temperature, the product was separated and washed several times with distilled water to remove the impurity ions contained in it. After drying, it was calcined at 550°C for 5 hours to obtain flaky γ-Al 2 o 3 The nano crystal grains have a length of 30-50nm and a thickness of 5-10nm. The alumina nanoparticles are characterized by powder X-ray diffraction as γ-Al 2 o 3 , the specific surface area is 133m 2 / g.

Embodiment 3

[0029] Prepare 10ml of 1mol / L aluminum nitrate solution and 43ml of 1mol / L sodium hydroxide solution, then mix the sodium hydroxide solution with the aluminum nitrate solution under 4KW / L ultrasound and stirring and stir evenly. The mixture was kept airtight under hydrothermal condition of 220°C for 6 hours. Then cooled to room temperature, the product was separated and washed several times with distilled water to remove the impurity ions contained in it. After drying, it was calcined at 650°C for 3 hours to obtain flaky γ-Al 2 o 3 The nano crystal grains have a length of 25-40nm and a thickness of 7-10nm. The alumina nanoparticles are characterized by powder X-ray diffraction as γ-Al 2 o 3 , the specific surface area is 125m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com