Advanced sewage treatment technology

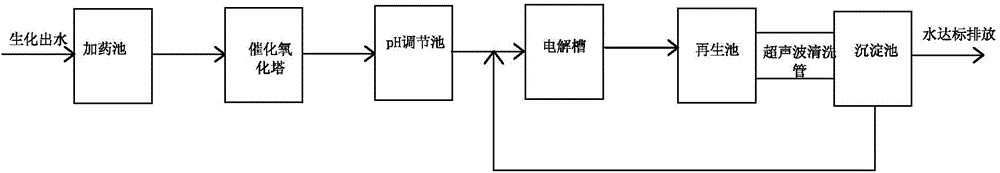

A technology for advanced treatment and sewage, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of catalyst being attached by dirt and high catalytic activity, and achieve the benefit of catalyst Regeneration, simple process, beneficial to the effect of activity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] When the COD of the treated sewage is less than 70mg / L, the sewage first enters the dosing tank, and a sodium hypochlorite solution with an effective chlorine content of 10% is added to the sewage, and the volume ratio of the sewage to the sewage is 0.2ml / L. The sewage then enters the catalytic oxidation tower, and the tower is filled fixed bed catalyst. In the pre-oxidation section, the reaction time is 20 minutes, and the COD drops below 65mg / L; then it enters the pH adjustment pool, uses 10% dilute sulfuric acid to adjust the pH of the sewage to 3.2, and then enters the electrolytic cell, in which the suspended particle catalyst is added. The volume of the oxidation pool is 10%. The electrolytic cell uses 316L stainless steel as the plate, the distance between each pair of electrodes is 3 cm, and a 4V DC voltage is applied to each pair of electrodes. The residence time of the sewage in the electrolytic cell is 30 minutes; the suspended particle catalyst flows to the ...

Embodiment 2

[0034] When the COD of the treated sewage is about 120mg / L, the sewage first enters the dosing tank, and 2ml / L (volume ratio to sewage) of sodium hypochlorite solution containing 10% available chlorine is added to the sewage, and the sewage enters the catalytic oxidation tower. The fixed bed catalyst is loaded in the middle, and the reaction time of the pre-oxidation section is 30 minutes, and the COD drops below 70mg / L; then enters the pH adjustment pool, uses 10% dilute sulfuric acid to adjust the pH of the sewage to 3.0, enters the electrolytic cell, and adds suspension to the electrolytic cell Granular catalyst, the catalyst accounts for 50% of the volume of the catalytic oxidation tank. The electrolytic cell uses 316L stainless steel as the plate, the distance between each pair of electrodes is 6 cm, and a 6V DC voltage is applied to each pair of electrodes. The residence time of the sewage in the electrolytic cell is 30 minutes; the suspended particle catalyst flows to th...

Embodiment 3

[0036] When the COD of the treated sewage is about 150mg / L, the sewage first enters the dosing tank, and 5ml / L (volume ratio to sewage) of sodium hypochlorite solution containing 10% available chlorine is added to the sewage, and the sewage enters the catalytic oxidation tower. The fixed bed catalyst is loaded in the middle, and the reaction time of the pre-oxidation section is 60min, and the COD drops below 90mg / L; then enters the pH adjustment pool, uses 10% dilute sulfuric acid to adjust the pH of the sewage to 3.5, enters the electrolytic cell, and adds suspension to the electrolytic cell Granular catalyst, the catalyst accounts for 40% of the volume of the catalytic oxidation tank. The electrolytic cell uses 316L stainless steel as the plate, the distance between each pair of electrodes is 6 cm, and a 5V DC voltage is applied to each pair of electrodes. The residence time of the sewage in the electrolytic cell is 60 minutes; the suspended particle catalyst flows to the reg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com