Wastewater pretreatment method for long-chain dibasic acid preparation process of biological fermentation method

A long-chain dibasic acid and biological fermentation technology, which is applied in the field of high-concentration wastewater pretreatment, can solve the problems of not considering the removal of total phosphorus and sulfate, not removing total phosphorus and sulfate, and exceeding the standard of total phosphorus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

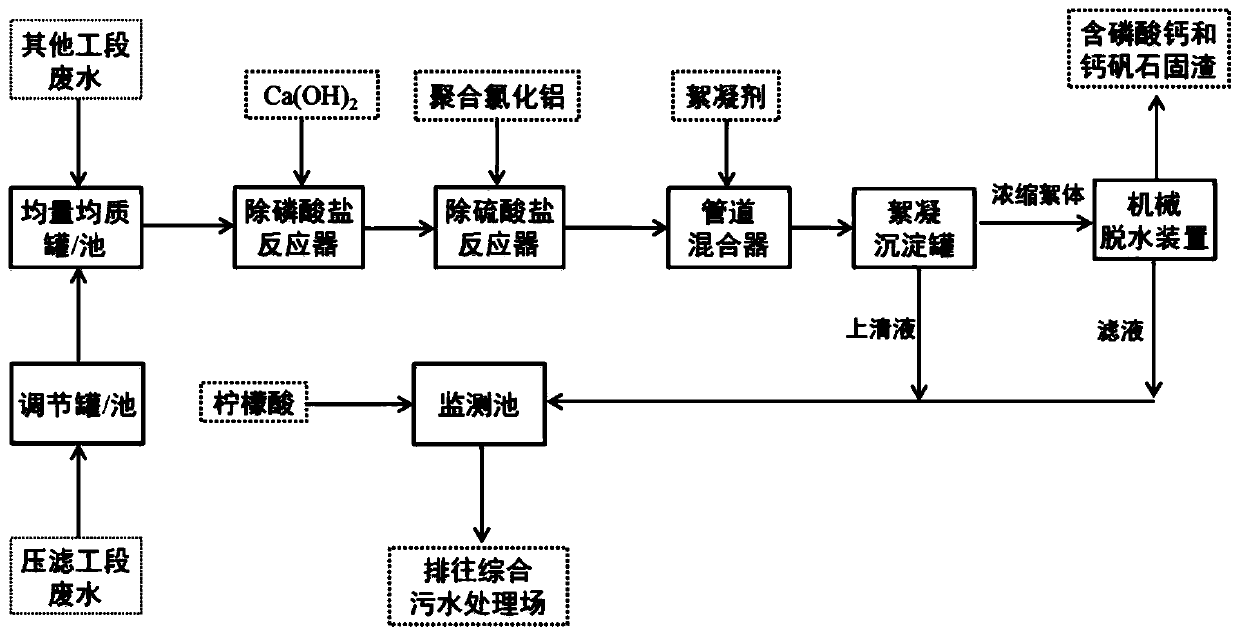

[0037] figure 1 It is a process flow diagram of the pretreatment method for preparing long-chain dibasic acid process wastewater (hereinafter referred to as the dibasic acid wastewater pretreatment method) by the biological fermentation method of this embodiment.

[0038] Such as figure 1 As shown, the dibasic acid wastewater pretreatment method of the present embodiment mainly includes the following steps:

[0039] 1) The wastewater from the filter press section intermittently discharged from the long-chain dibasic acid preparation process is sent to the regulating tank / pool for accumulation, and then enters the homogenizing tank / pool (that is, the total collection pool) to mix with the wastewater discharged from other sections for homogenization become mixed wastewater;

[0040] 2) The homogenized mixed wastewater enters the phosphate removal reactor, and the excess calcium hydroxide (Ca(OH) 2 ) mixed reaction, obtains the first suspension that generates calcium phosphate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com