A kind of high hardness floor and preparation method thereof

A high-hardness, floor technology, applied in the field of floor, can solve the problems of limited floor color, inconvenient construction, inability to add water, etc., and achieve the effect of low cost, suitable for promotion, and rich pattern varieties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

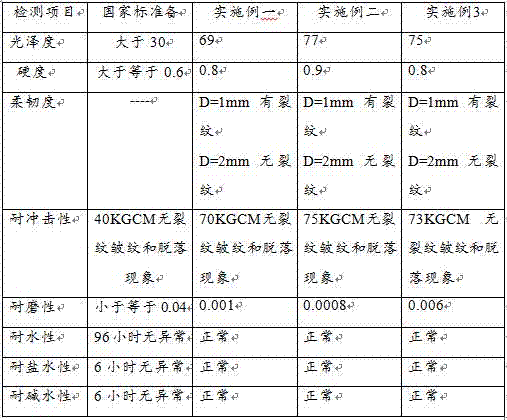

Examples

Embodiment 1

[0026] The raw material formula of this embodiment is: 22 parts by weight of cement, 35 parts by weight of granite production waste, 12 parts by weight of cullet of 4-40 mesh, 10 parts by weight of fly ash, 10 parts by weight of calcium carbide mud, 2 parts by weight of softener, 1 part by weight of pigment, 0.5 part by weight of fungicide, 0.5 part by weight of early strength agent, 0.2 part by weight of antiaging agent, 0.2 part by weight of coupling agent, 1 part by weight of emulsifier, 0.5 part by weight of leveling agent, 5.1 part by weight of epoxy resin And 5.1 parts by weight of epoxy resin curing agent;

[0027] Wherein, the cement is 425# Portland cement.

[0028] Wherein, the granite waste material is fragments and powder produced in the process of processing granite, and the composition of the granite production waste material is 78 parts by weight of silicon dioxide, 15 parts by weight of calcium carbonate, 0.1 parts by weight of aluminum silicate and 0.1 parts b...

Embodiment 2

[0043]The raw material formula of this embodiment is: 26 parts by weight of cement, 30 parts by weight of granite production waste, 10 parts by weight of cullet of 4-40 mesh, 11 parts by weight of fly ash, 12 parts by weight of calcium carbide mud, 1 part by weight of softener, 1 part by weight of pigment, 0.5 part by weight of fungicide, 0.5 part by weight of early strength agent, 0.2 part by weight of antiaging agent, 0.2 part by weight of coupling agent, 1 part by weight of emulsifier, 0.5 part by weight of leveling agent, 7.1 part by weight of epoxy resin And 7.1 parts by weight of epoxy resin curing agent;

[0044] Wherein, the cement is 425# Portland cement.

[0045] Wherein, the granite production waste is fragments and powder produced in the process of processing granite, and the granite production waste composition is 78 parts by weight of silicon dioxide, 21 parts by weight of calcium carbonate, 0.1 parts by weight of aluminum silicate and 0.1 parts by weight. The p...

Embodiment 3

[0060] The raw material formula of this embodiment is: 20 parts by weight of cement, 30 parts by weight of granite production waste, 20 parts by weight of cullet of 4-40 mesh, 15 parts by weight of fly ash, 15 parts by weight of calcium carbide mud, 3 parts by weight of softener, 1 part by weight of pigment, 2 parts by weight of fungicide, 1 part by weight of early strength agent, 0.5 part by weight of antioxidant, 0.2 part by weight of coupling agent, 1 part by weight of emulsifier, 0.5 part by weight of leveling agent, 3 parts by weight of epoxy resin With 3 parts by weight of epoxy resin curing agent;

[0061] Wherein, the cement is 425# Portland cement.

[0062] Wherein, the granite production waste is fragments and powders produced in the process of processing granite, and the granite production waste composition is 70 parts by weight of silicon dioxide, 15 parts by weight of calcium carbonate, 0.1 parts by weight of aluminum silicate and 0.1 parts by weight Potassium si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com