Straight hole ceramic filter

A ceramic filter, filter technology, applied in the field of silicate materials and industrial ceramics, can solve problems such as product introduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

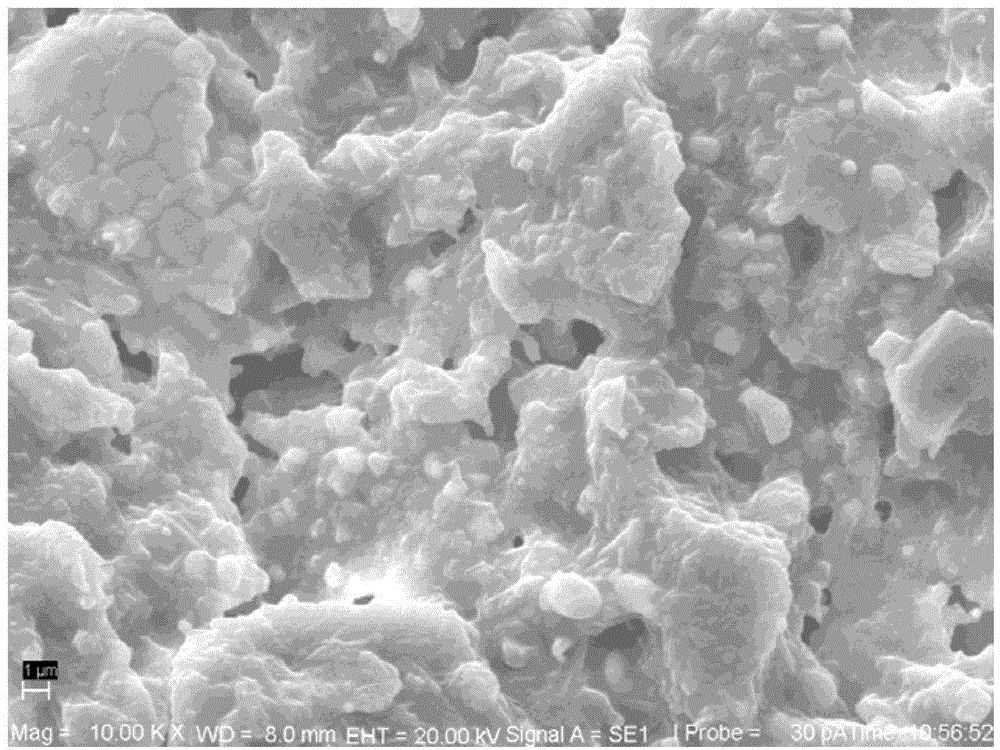

Embodiment 1

[0044] Preparation materials: zirconia corundum brick polishing waste (1000 mesh, zirconia content ≥ 12%, alumina content ≥ 60%) 170 kg, corundum powder (325 mesh, alumina content ≥ 99%, corundum phase content ≥ 95%) 20 Kg, Suzhou kaolin (500 mesh, alumina content ≥30%, silica content ≥45%) 10 kg, polyvinyl alcohol (PVA content ≥6%) aqueous solution 10 kg, emulsified paraffin (commercially available industrial grade) 1.5 kg , sodium tripolyphosphate (commercially available industrial grade) 0.7 kg, add 120 kg of water, ball mill for 6 hours, and prepare slurry;

[0045] Pressure spray granulation: adopt the pressure spray granulation equipment introduced in patent 200810182753.3, the spray pressure is controlled at 1.2MPa, the nozzle diameter is 1.2mm, the water content of the obtained granulated material is controlled at 2-4%, and the bulk density of the granulated material is 0.95-1.1 g / cm 3 ;

[0046] Compression molding: Put the above powder into a mold cavity with a dia...

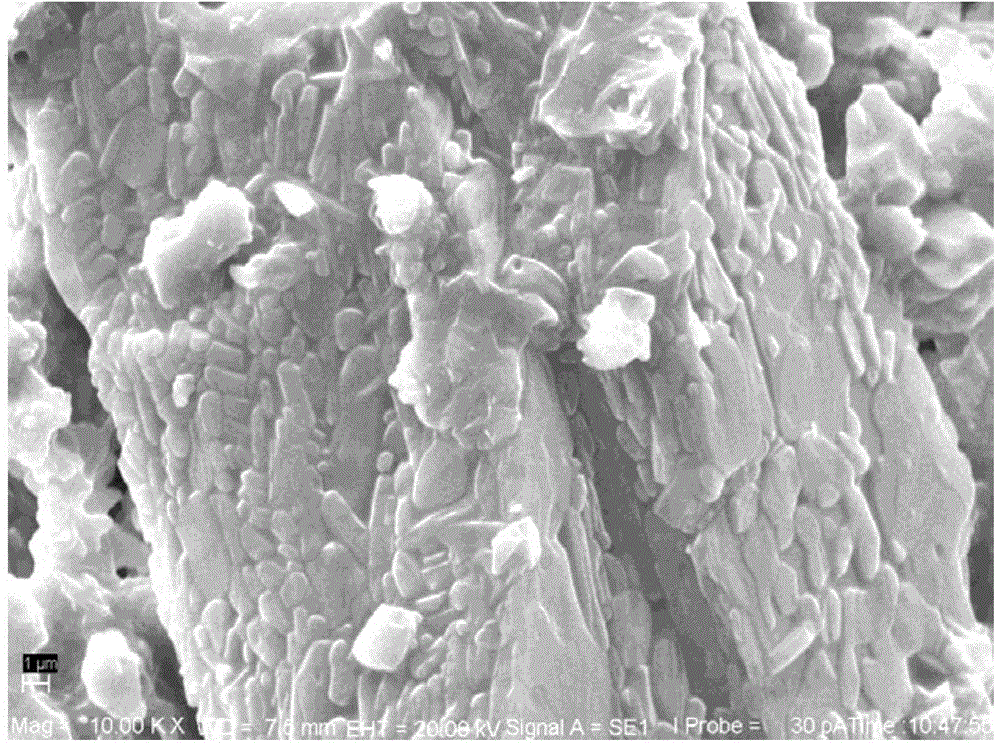

Embodiment 2

[0050] The straight hole ceramic filter is 75mm*75mm*20mm in size, the hole type is 3.0mm*3.0mm square hole, and the rib thickness is 1.0mm. Raw materials with a weight ratio of zirconium corundum brick polishing waste (particle size less than 1000 mesh), alumina (particle size less than 325 mesh), and Suzhou kaolin (particle size less than 500 mesh) after ball milling and sieving Mixed into 200Kg, add 4% hydroxypropyl methylcellulose of raw material weight, mix for 2 hours, after crossing 100 mesh sieves, add water of 18% of raw material gross weight, 3% tung oil and 3% rapeseed oil, knead Knead in the machine for 20 minutes, and then seal and stale for 18-24 hours after the mud is practiced 3 times by the mud refining machine. After the stale mud is subjected to vacuum refining, it is extruded with the corresponding mold of the above-mentioned filter. After the extruded body is shaped by a box-type microwave oven, it is dried with circulating warm air in a box-type oven at 6...

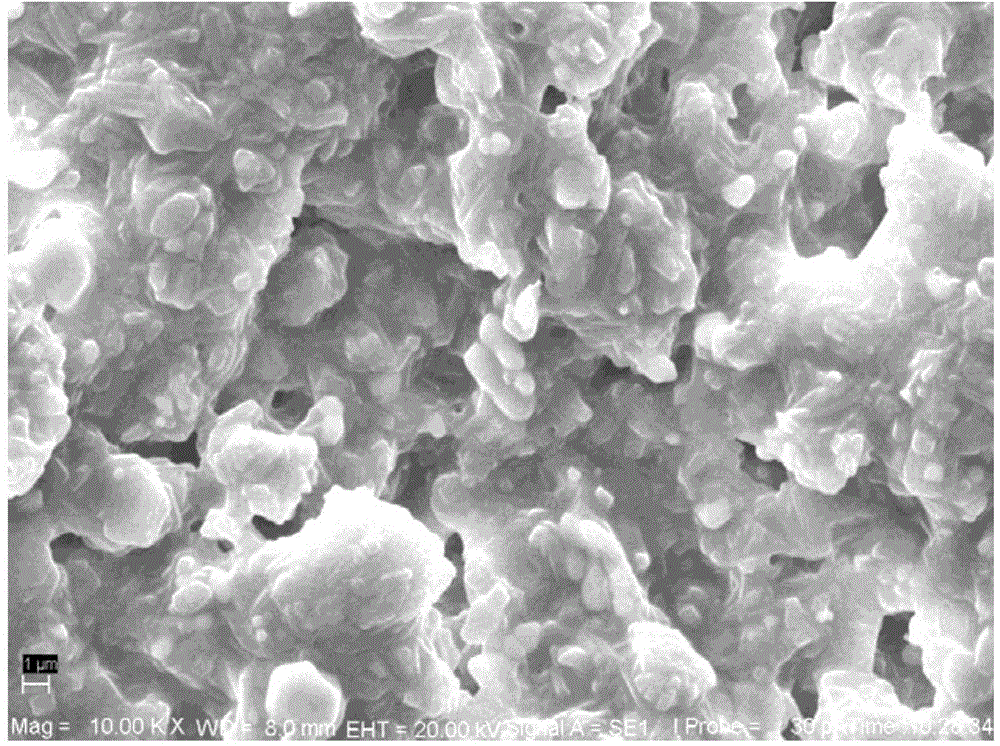

Embodiment 3

[0052] Materials: zirconium corundum brick polishing waste (1000 mesh, zirconia content ≥ 12%, alumina content ≥ 60%) 190 kg, Suzhou kaolin (500 mesh, alumina content ≥ 30%, silica content ≥ 45% ) 10 kg, polyvinyl alcohol (PVA content ≥ 6%) aqueous solution 10 kg, emulsified paraffin (commercially available industrial grade) 1.5 kg, sodium tripolyphosphate (commercially available industrial grade) 0.7 kg, add water 120 kg, ball mill for 6 hours, prepared into a slurry;

[0053] Pressure spray granulation: adopt the pressure spray granulation equipment introduced in patent 200810182753.3, the spray pressure is controlled at 1.2MPa, the nozzle diameter is 1.2mm, the water content of the obtained granulated material is controlled at 2-4%, and the bulk density of the granulated material is 0.95-1.1 g / cm 3 ;

[0054] Compression molding: put the above powder into a mold cavity with a size of 100mm*60*22mm, a round hole, and a hole diameter of 3.0mm, and press it with a JT-5 hydra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com