Preparation method of mushroom cultivation material

The technology of a shiitake mushroom cultivation material and a production method, which is applied in the production field of shiitake mushroom cultivation materials, can solve the problems of clinker cultivation cost increase, cultivation material nutrient loss, and cultivation material conversion rate reduction, so as to save manpower, improve microbial flora, The effect of promoting the reproduction of beneficial microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

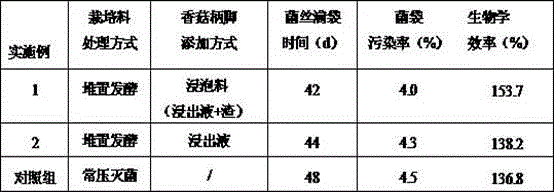

Examples

Embodiment 1

[0018] Embodiment 1: A kind of preparation method of shiitake mushroom cultivation material, comprising batching, fermenting, turning, bagging, inoculation, germination, specific operation steps:

[0019] ①Ingredients: wood chips 57%, cottonseed hulls 16%, bran 19%, mushroom tang 4.5%, lime 2.5%, gypsum 1%, all of which are the quality of dry matter, and the sum of the proportions is 100%;

[0020] ②Fermentation: Add 20-30 times the weight ratio of mushroom shank granules to clean water, soak at room temperature for 18h-24h, then mix the leachate and mushroom stalk residue evenly into the mixture of wood chips and cottonseed shells, and pile Make a trapezoidal pile with a height of 1.0m-1.2m, a width of 2m-3m, and an unlimited length. The compost for each pile should be controlled at a dry weight of 300kg-500kg. Wooden sticks are inserted into the pile with some vertical air holes, which go straight to the bottom of the pile, and the density of air holes is 1 / m 3 , and finall...

Embodiment 2

[0023] Embodiment 2: A kind of preparation method of shiitake mushroom cultivation material, comprises batching, fermenting, turning over, bagging, inoculation, germination, specific operation steps:

[0024] ①Ingredients: wood chips 57%, cottonseed hulls 16%, bran 19%, mushroom tang 4.5%, lime 2.5%, gypsum 1%, all of which are the quality of dry matter, and the sum of the proportions is 100%;

[0025] ②Fermentation: Add 20-30 times the weight ratio of shiitake mushroom shank particles to clean water, soak at room temperature for 18h-24h, then mix the leachate after removing residue evenly into the wood chips and cottonseed shell mixture, and pile the material into The height is 1.0m-1.2m, the width is 2m-3m, and the length is not limited to trapezoidal piles. The compost in each pile should be controlled at a dry weight of 300kg-500kg. The rods are inserted some vertical air holes on the pile, which go straight to the bottom of the pile, and the air hole density is 1 / m 3 , a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com