Method for preparing intermediate of ecteinascidin-743

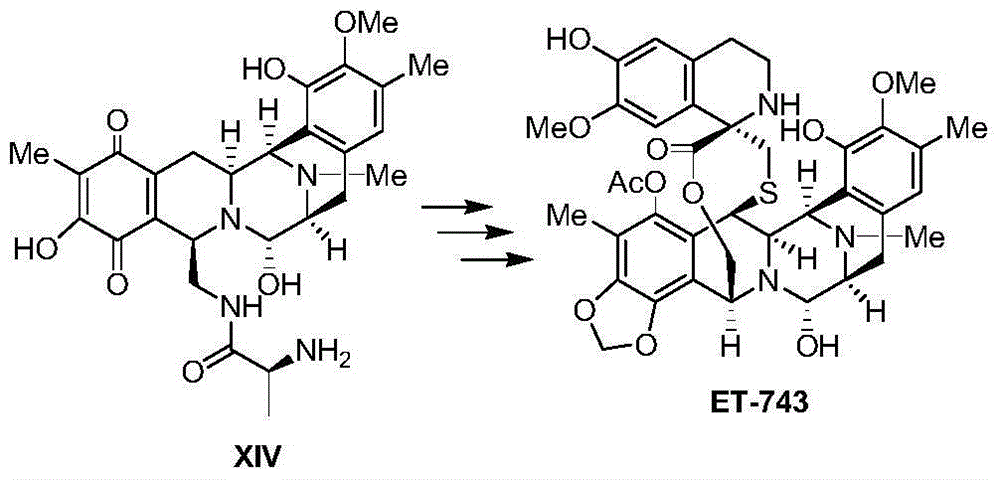

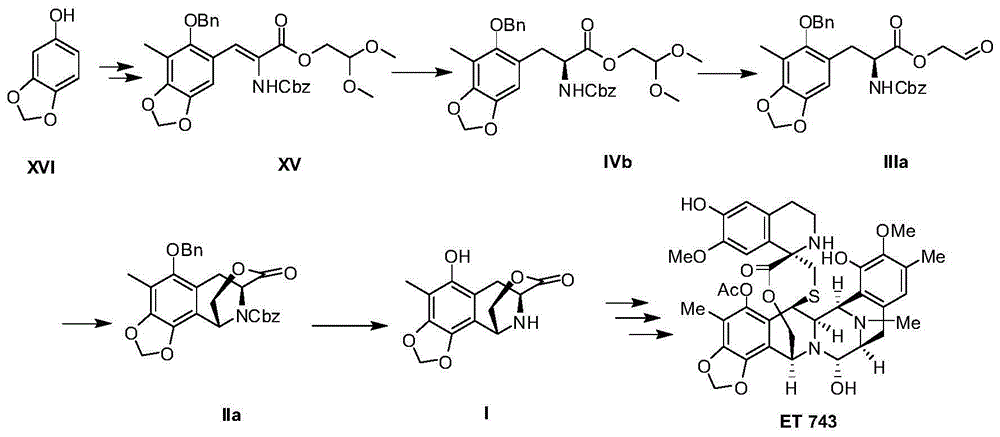

A compound and protecting group technology, which is applied in the preparation field of ascidine-743 intermediate, can solve the problems of cumbersome operation, unsuitability for large-scale production, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

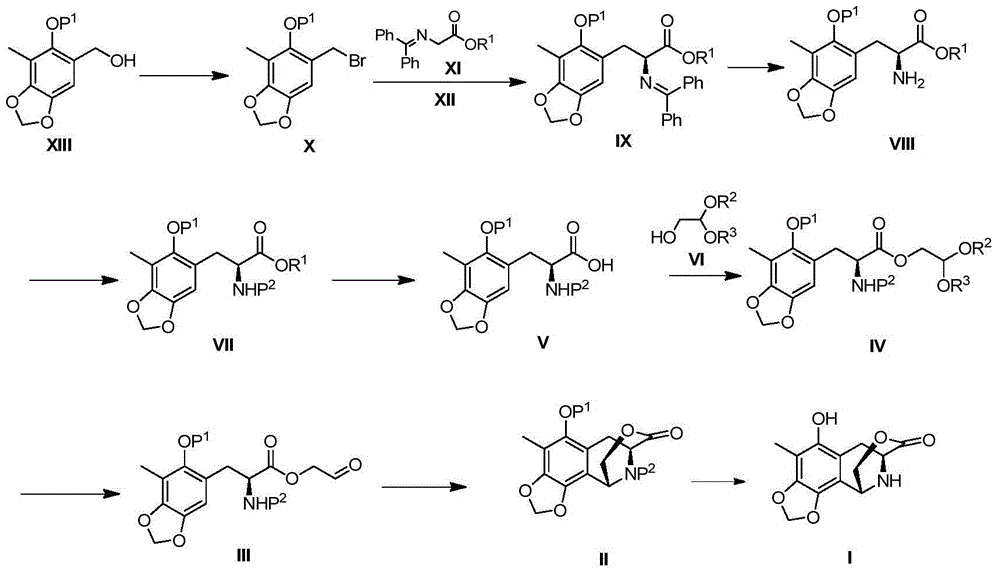

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1: Preparation of compound Xa

[0078] Compound XIIIa (120g, prepared according to the literature J.Am.Chem.Soc.1997,119,12414) was dissolved in dichloromethane (240mL) and toluene (70mL), and after cooling down to 10 degrees, tribrominated Phosphorus (240g) was reacted at 20°C for 2 hours, water (240mL) was added to quench the reaction, the organic phase was dried over anhydrous sodium sulfate, and concentrated to obtain compound Xa (140g, yield 95%).

[0079] 1 H-NMR (400MHz, CDCl 3 )δ7.52-7.50 (m, 2H), 7.44-7.36 (m, 3H), 6.71 (s, 1H), 5.96 (s, 2H), 4.95 (s, 2H), 4.54 (s, 2H), 2.20 (s,3H).

Embodiment 2

[0080] Embodiment 2: preparation compound IXa

[0081] Compound XIa (24g, prepared according to the document J.Org.Chem.1982,47,2663) was dissolved in toluene (600mL), and the chiral phase transfer catalyst XIIa (4.9g, prepared according to the document J.Am.Chem.Soc. 1997,119,12414), after cooling to -20 degrees, add cesium hydroxide hydrate (68.2g) and compound Xa (29.8g), react at -20 degrees for 15 hours, add tert-butyl methyl ether (240mL) , the organic phase was dried with anhydrous sodium sulfate, concentrated, and purified by column chromatography to obtain compound IXa (38 g, yield 75%, 95% ee).

[0082] 1 H-NMR (400MHz, CDCl 3 )δ7.59-7.56(m,2H),7.37-7.25(m,2H),6.76-6.74(m,2H),6.46(s,1H),5.87(s,2H),4.71-4.68(d, 1H),4.46-4.43(d,1H),4.28-4.24(m,1H),4.13-4.11(m,1H),3.30-3.25(m,1H),3.12-3.06(m,1H),2.09( s,3H), 1.42(s,9H).

Embodiment 3

[0083] Embodiment 3: preparation compound VIIIa

[0084]Dissolve compound IXa (57.5g) in tetrahydrofuran (690mL), add 0.5M citric acid aqueous solution (265mL), react at 20°C for 10 hours, add sodium bicarbonate to neutralize the reaction solution, add ethyl acetate (345mL) to extract , the organic phase was dried with anhydrous sodium sulfate, concentrated, and purified by column chromatography to obtain compound VIIIa (38.1 g, yield 88%).

[0085] 1 H-NMR (400MHz, CDCl 3 )δ7.47-7.45(m,2H),7.41-7.32(m,3H),6.56(s,1H),5.92(s,2H),4.78(s,2H),3.64-3.61(m,1H) ,3.04-2.99(m,1H),2.66-2.60(m,1H),2.19(s,3H),1.42(s,9H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com