Solid Phase Fragment Synthesis of Thymosin α1

A synthetic method and technology of thymosin, which is applied in the field of solid-phase fragment synthesis of thymosin α1, can solve the problems of complex preparation process of pseudoproline dipeptide, difficulty in large-scale preparation, and high price, and achieve low cost and reduced production The effect of shortening the cost and production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

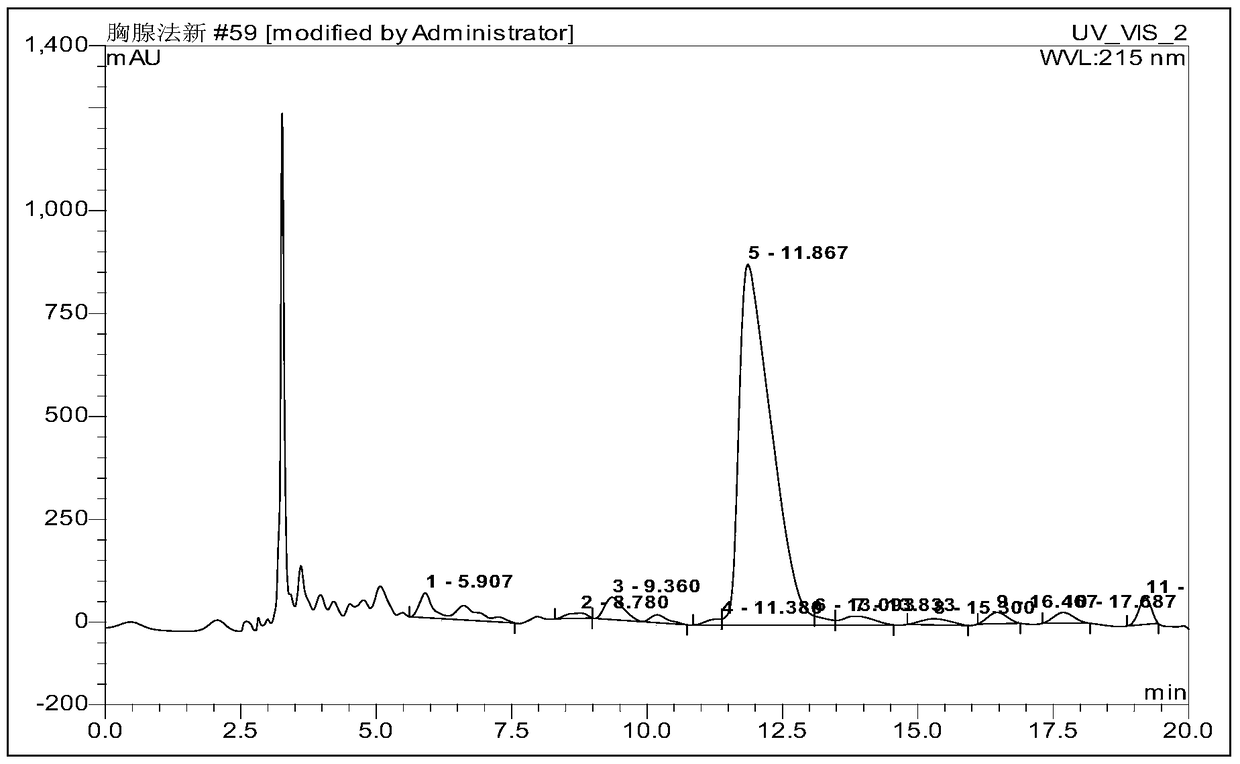

[0047] According to the "fragment Ac(1-4) + stepwise condensation of 5-14 amino acids + Fmoc (15-22) + (23-28)-Wang Resin" synthesis strategy to synthesize the three required fragments, the process flow chart is as follows:

[0048] Ⅰ. Preparation (23-28) - Wang Resin

[0049]

[0050] Ⅱ. Preparation of Fragment Fmoc(15~22) Fully Protected Crude Peptide

[0051]

[0052] Ⅲ. Condensation of fragment Fmoc (15~22) fully protected crude peptide and (23~28)-Wang Resin, and gradually condense to the fifth amino acid

[0053]

[0054] Ⅳ. Preparation of Fragment Ac(1~4) Fully Protected Crude Peptide

[0055]

[0056] Ⅴ. Fragment Ac(1~4) fully protected crude peptide is condensed with (5~28)-Wang Resin, and cracked into crude peptide

[0057]

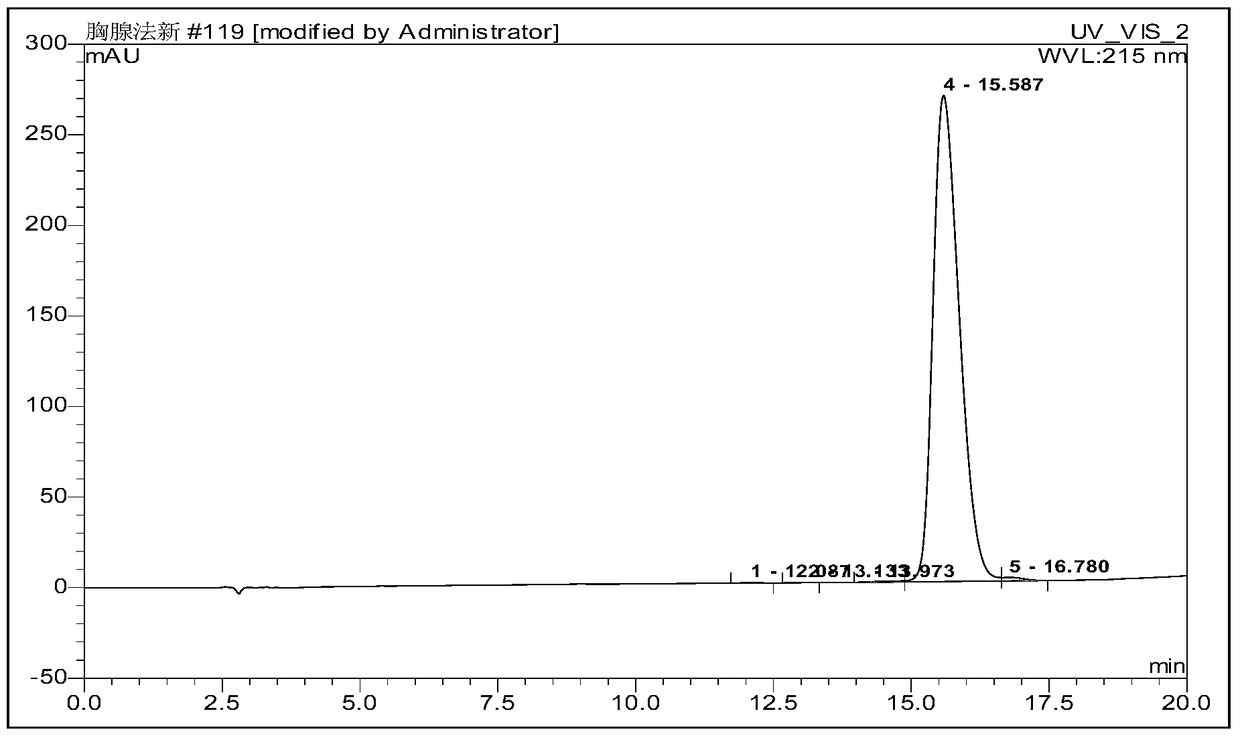

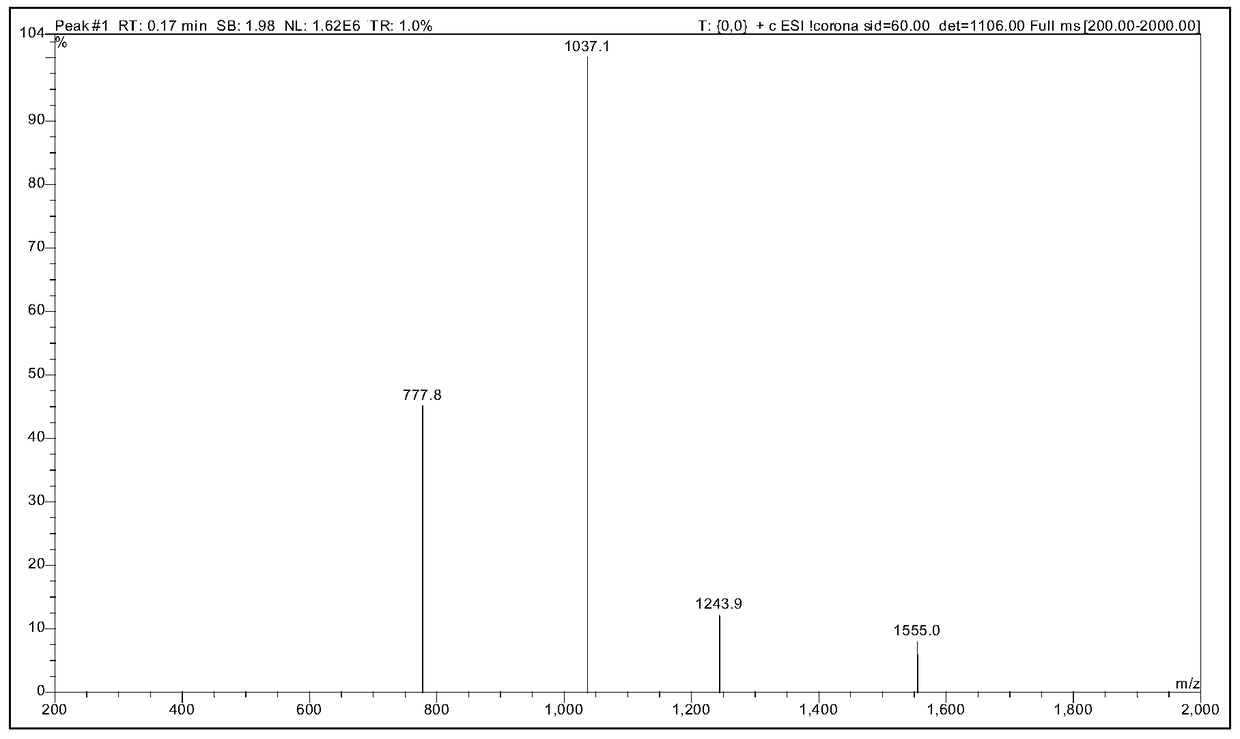

[0058] Ⅵ. Purification and desalting of crude peptide

[0059]

[0060] (1) Synthesis of fully protected peptide resin of C-terminal fragment A (AA23-AA28) H-Val-Glu(OtBu)-Glu(OtBu)-Ala-Glu(OtBu)-Asn(Trt)-Wang Resin

[0061...

Embodiment 2

[0096] (1) Four fragments were synthesized according to the synthesis strategy of "fragment Ac(1~2)+ stepwise condensation of amino acids at positions 3~14+Fmoc(15~24)+(25~28)-WangResin". The process flow chart is as follows:

[0097] Ⅰ. Preparation (25~28)-Wang Resin

[0098]

[0099] Ⅱ. Preparation of Fmoc(15~24) Fully Protected Crude Peptide

[0100]

[0101] Ⅲ. Condensation of fragment Fmoc (15~24) fully protected crude peptide and (25~28)-Wang Resin, and gradually condense to the third amino acid

[0102]

[0103] Ⅳ. Preparation of Fragment Ac(1~2) Fully Protected Crude Peptide

[0104]

[0105] Ⅴ. Condensation of fragment Ac(1~2) fully protected crude peptide with (3~28)-Wang Resin, and cleavage into crude peptide

[0106]

[0107] Ⅵ. Purification and desalting of crude peptide

[0108]

[0109] The specific operation is as follows:

[0110] a. Synthetic Fragment (25~28)-Wang Resin: Weigh 920.0g Wang Resin (1.2mmol / g) into a 10L reactor, add an appr...

Embodiment 3

[0126] (1) Synthesize the three required fragments according to the synthetic strategy of "Ac+ Fmoc(1~4)+ stepwise condensation of amino acids at positions 5~14+Fmoc(15~22)+(23~28)-WangResin". The process flow chart is as follows :

[0127] Ⅰ. Preparation (23~28)-Wang Resin

[0128]

[0129] Ⅱ. Preparation of Fragment Fmoc(15~22) Fully Protected Crude Peptide

[0130]

[0131] Ⅲ. Condensation of fragment Fmoc (15~22) fully protected crude peptide and (23~28)-Wang Resin, and gradually condense to the fifth amino acid

[0132]

[0133] Ⅳ. Preparation of Fragment Fmoc(1~4) Fully Protected Crude Peptide

[0134]

[0135] Ⅴ. Fragment Fmoc(1~4) fully protected crude peptide is condensed with (5~28)-Wang Resin, acetylated and cracked into crude peptide

[0136]

[0137] Ⅵ. Purification and desalting of crude peptide

[0138]

[0139] The specific operation is as follows:

[0140] a. Synthesis of (23~28)-Wang Resin: Weigh 1100.0g Wang Resin (1.0mmol / g) into a 10L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com