Solid catalyst component and catalyst for olefin polymerization

A solid component, olefin polymerization technology, applied in the field of olefin polymerization, can solve the problems of low polymer melt flow rate melt index, poor sensitivity of molecular weight regulators, and insufficient polymer molecular weight distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

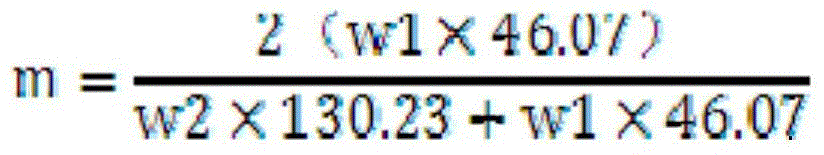

[0081] Preparation of magnesium alkoxide

[0082] Alkoxy magnesium support (1)Mg(OEt) 2-m (OEHA) m Preparation of:

[0083] After fully replacing the 16L pressure-resistant reactor with agitator with nitrogen, add 10L ethanol, 300mL 2-ethylhexanol, 11.2g iodine, 8g magnesium chloride and 640g magnesium powder into the reactor. While stirring, the temperature of the system was raised to 75° C. for reflux reaction until no more hydrogen gas was discharged. Stop the reaction, wash with 3L ethanol, filter and dry. The obtained alkoxymagnesium support. The D50 of the obtained alkoxymagnesium carrier is 30.2um, the span value is 0.81, and the m value is 0.015.

[0084] Alkoxy magnesium support (2)Mg(OEt) 2 Preparation of:

[0085] The preparation method is the same as that of the alkoxymagnesium carrier a1, except that 300mL of 2-ethylhexanol is replaced by 300mL of ethanol. The D50 of the obtained alkoxymagnesium carrier was 37.3um, the span value was 1.51, and the m value ...

Embodiment 1

[0087] The preparation of catalyst solid component A1:

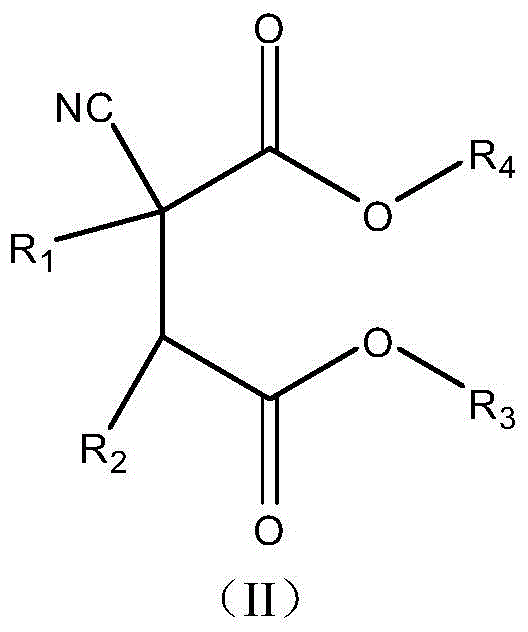

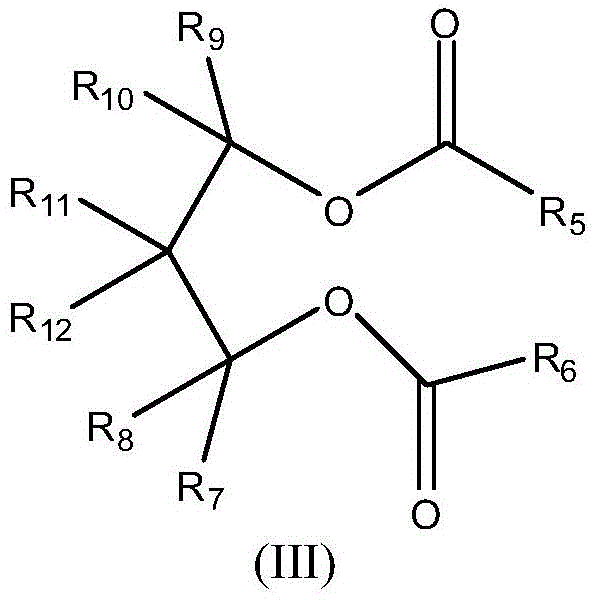

[0088] Take 10g of alkoxymagnesium compound (1), 50mL of toluene, 1.5mmol of diethyl 2,3-diisopropyl-2-cyanosuccinate (compound a, prepared with reference to the preparation method in CN101811983A) and 6.0mmol3, 5-heptanediol dibenzoate (compound b, prepared with reference to the preparation method in CN1213080C) was formulated into a suspension. In a 300mL reaction kettle that has been repeatedly replaced by high-purity nitrogen, add 40mL of toluene and 60mL of titanium tetrachloride, heat up to 80°C, then add the prepared suspension into the kettle, keep the temperature for 1 hour, slowly raise the temperature to 110°C, and keep the temperature constant After 2 hours, the solid was obtained by pressure filtration. The resulting solid was added to a mixture of 78 mL of toluene and 52 mL of titanium tetrachloride and stirred at 110° C. for 1 hour, and treated like this three times. Press-filtered, the obtained solid wa...

Embodiment 2-4、 comparative example 1-4

[0095] The preparation method and polymerization method of the catalyst solid components A2, A3, A4, B1, B2, B3, and B4 are the same as in Example 1, except that 2,3-diisopropyl-2-cyanosuccinate diethyl Amounts of ester (a) and 3,5-heptanediol dibenzoate (b). The solid components and compositions of the obtained catalysts are shown in Table 1.

[0096] The steps of the olefin polymerization reaction are the same as in Example 1, except that the catalyst solid components A2, A3, A4, B1, B2, B3, and B4 are used respectively. See Table 2 for the data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com