Nano-particle composite with double-shell microstructure and application of nano-particle composite

A microstructure and nanoparticle technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as narrow absorption frequency band, achieve wide absorption frequency band, broad application prospects, and high absorption strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

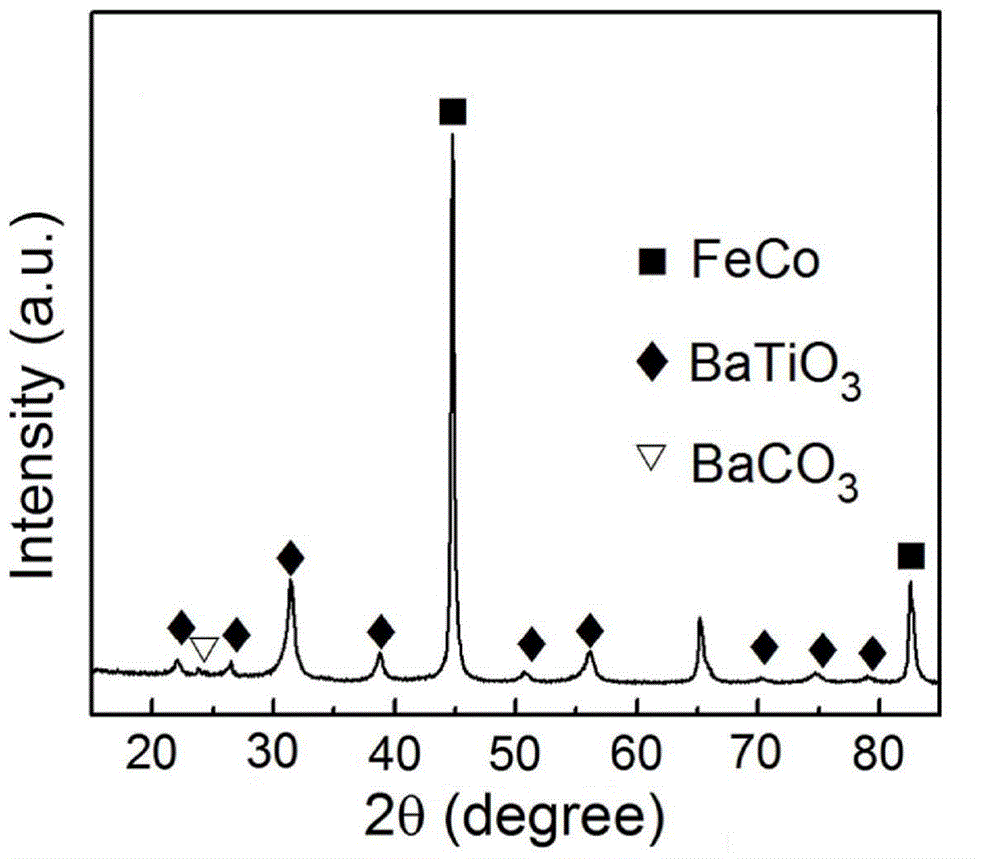

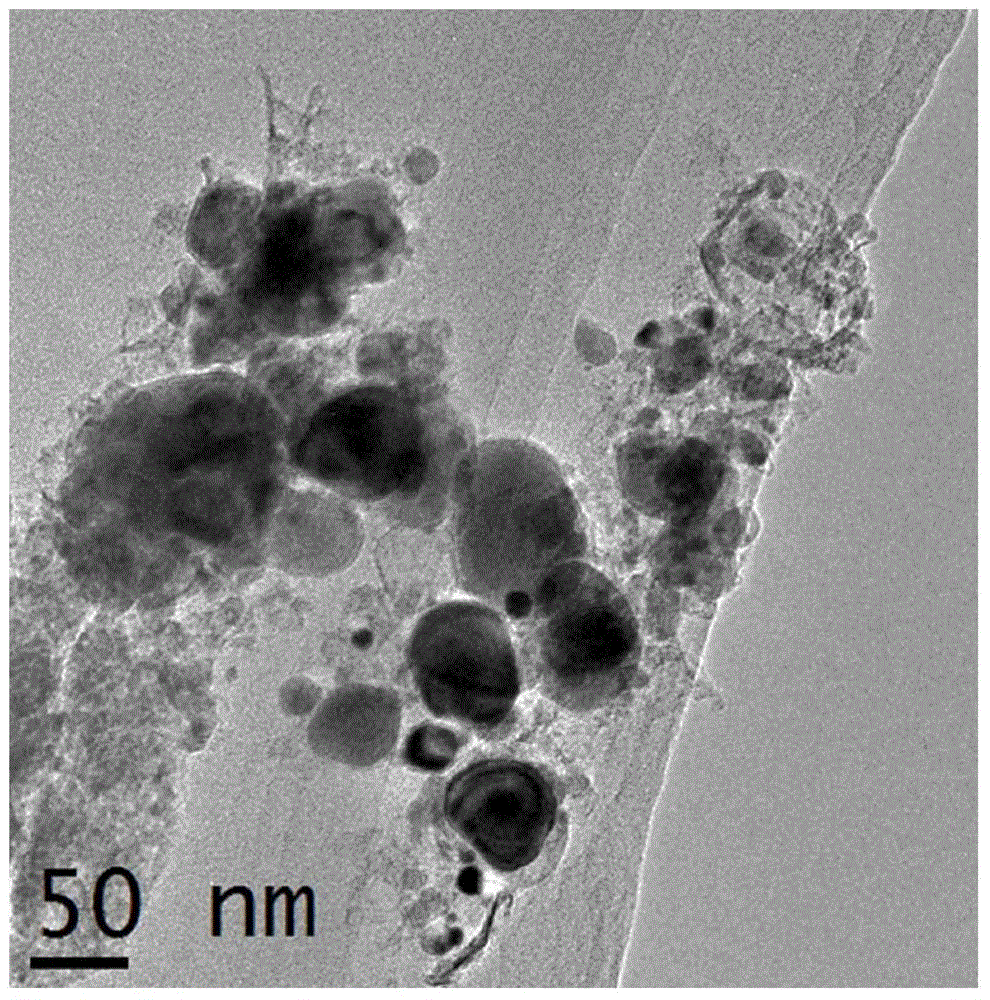

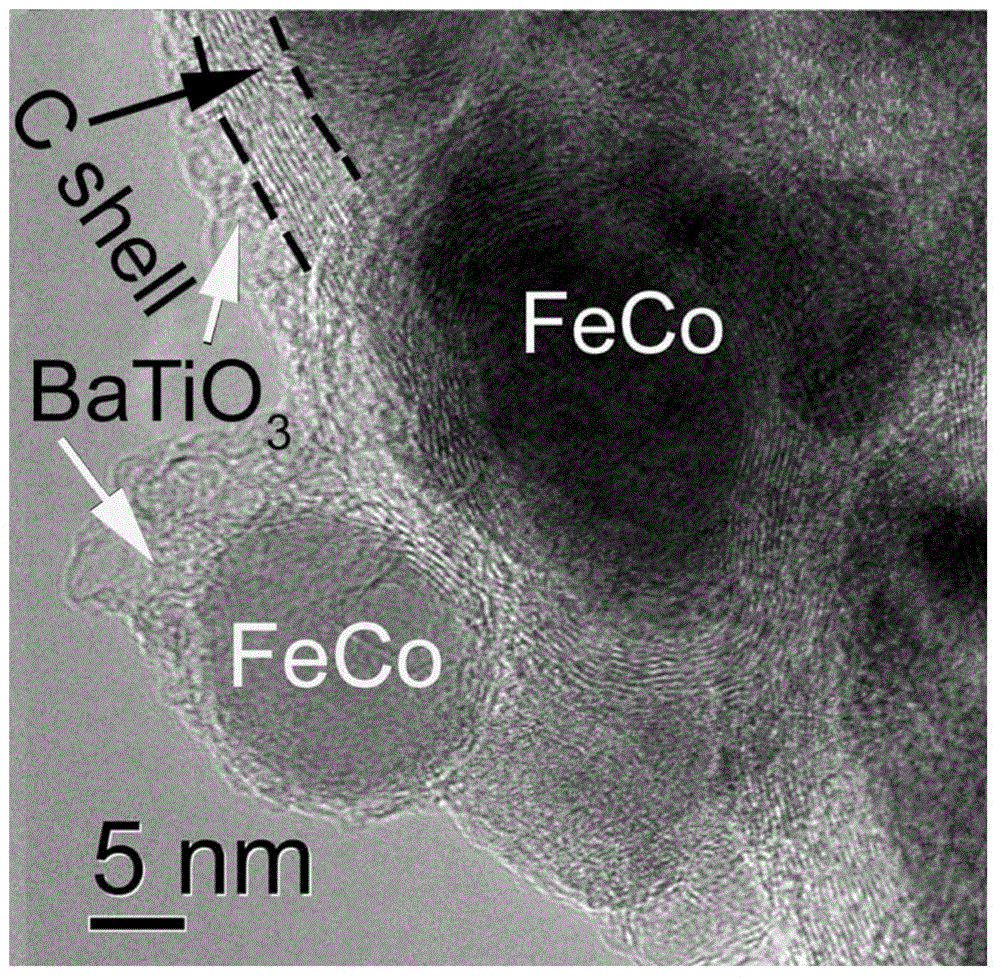

Embodiment 1

[0030] The preparation steps of the double-shell wrapped nanoparticle composite microwave absorbing material are:

[0031] (1) Barium titanate gel was prepared by sol-gel method using barium acetate and isopropyl titanate as starting materials;

[0032] (2) Disperse magnetic carbon-coated iron-cobalt nanocapsules in n-hexane to form magnetic carbon-coated iron-cobalt nanocapsules-n-hexane suspension;

[0033] (3) Prepare an aqueous solution containing n-hexane, water, ethanol and polyvinylpyrrolidone;

[0034] (4) Mix magnetic carbon-coated iron-cobalt nanocapsules-n-hexane suspension with aqueous solution, and prepare o / w microemulsion by ultrasonic method, in which polyvinylpyrrolidone is the emulsifier;

[0035] (5) Add the dielectric oxide gel to the o / w microemulsion, and form a uniformly dispersed magnetic carbon-coated iron-cobalt nanocapsule-dielectric oxide sol precursor solution by ultrasonic oscillation;

[0036] (6) Dry the precursor solution of magnetic carbon-c...

Embodiment 2

[0041] The difference from Example 1 is that the mass ratio of barium titanate: carbon-coated iron-cobalt nanocapsules is 50wt.%: 50wt.%. By adjusting the thickness of the absorbing layer, the reflection loss (RL) has an absorption lower than -20dB at different frequencies (see Figure 7 ).

Embodiment 3

[0043] The difference from Example 1 is that the mass ratio of barium titanate: carbon-coated iron-cobalt nanocapsules is 80wt.%: 20wt.%. After testing, the reflection loss (RL) of the obtained composite material has an absorption lower than -15dB at different frequencies (see Figure 8 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com