Method for environment-friendly preparation of fluorescent silicon nanoparticles

A silicon nanoparticle, fluorescence technology, applied in nanotechnology, nano-optics, nanotechnology and other directions, to achieve the effect of cheap raw materials, low toxicity and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Pretreatment with acid

[0021] The rice hulls washed with deionized water were heated under reflux in a 10 wt% hydrochloric acid water bath for 3 h.

[0022] (2) Preparation of silica samples

[0023] Put the treated rice husk in a porcelain crucible and heat it with an alcohol lamp until it turns off-white.

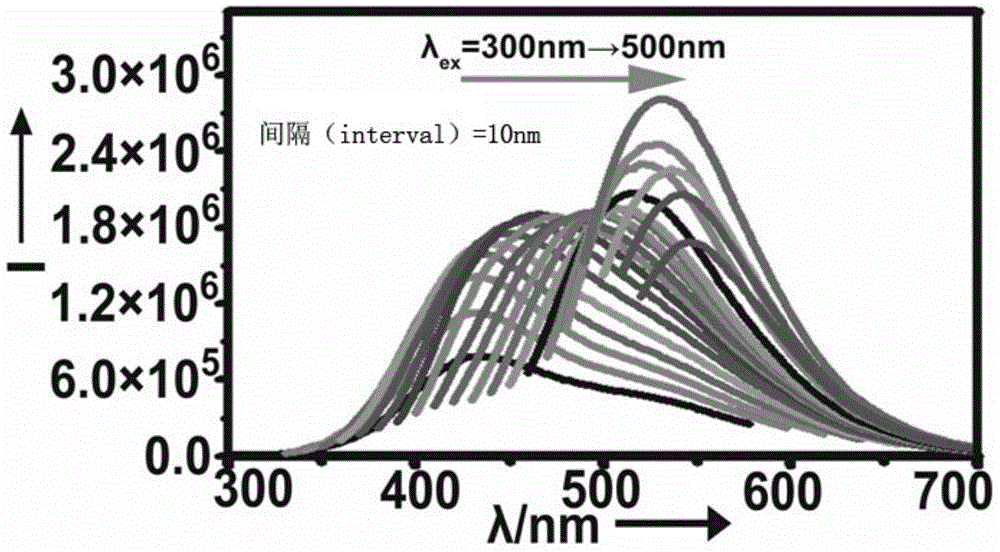

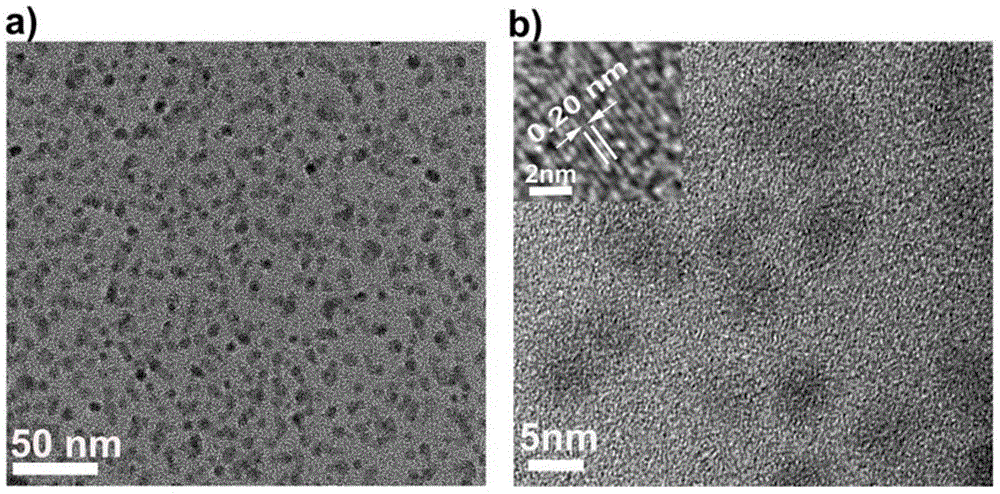

[0024] (3) Preparation of fluorescent silicon nanoparticles by microwave irradiation

[0025] Take 0.04g of silicon dioxide sample, add 10mL of 0.5mol / L NaOH solution, place it in a glass tube dedicated to microwave radiation for microwave radiation, and obtain fluorescent silicon nanoparticles.

[0026] Microwave radiation conditions are: microwave power 600W; temperature: 100°C; time: 2h.

Embodiment 2

[0028] (1) Pretreatment with acid

[0029] The wheat stalks washed with deionized water were heated under reflux in a 10 wt% hydrochloric acid water bath for 3 h.

[0030] (2) Preparation of silica samples

[0031] Put the treated wheat stalks in a porcelain crucible and heat them with an alcohol lamp until they turn off-white.

[0032] (3) Preparation of fluorescent silicon nanoparticles by microwave irradiation

[0033] Take 0.05g of silicon dioxide sample, add 10mL of 0.5mol / L KOH solution, place it in a glass tube dedicated to microwave radiation for microwave radiation, and obtain fluorescent silicon nanoparticles.

[0034] Microwave radiation conditions are: microwave power 600W; temperature: 110°C; time: 2.5h.

Embodiment 3

[0036] (1) Pretreatment with acid

[0037] The bagasse washed with deionized water was heated under reflux in a 20 wt% hydrochloric acid water bath for 2 h.

[0038] (2) Preparation of silica samples

[0039] Put the processed bagasse in a porcelain crucible and heat it with an alcohol lamp until it turns off-white.

[0040] (3) Preparation of fluorescent silicon nanoparticles by microwave irradiation

[0041] Take 0.03g of silicon dioxide sample, add 10mL of 0.6mol / L NaOH solution, place it in a glass tube dedicated to microwave radiation for microwave radiation, and obtain fluorescent silicon nanoparticles.

[0042] Microwave radiation conditions are: microwave power 600W; temperature: 130°C; time: 3h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com