A kind of isopropanol urea dewaxing method

A technology of isopropanol and dewaxing, which is applied in the recovery/refining of mineral wax, petroleum industry, and only multi-stage serial refining process treatment, etc. It can solve the problems of low water temperature requirements, pipeline blockage, and reduced heat exchange effect. To achieve the effect of simplifying the process, good protection, and saving low-temperature water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

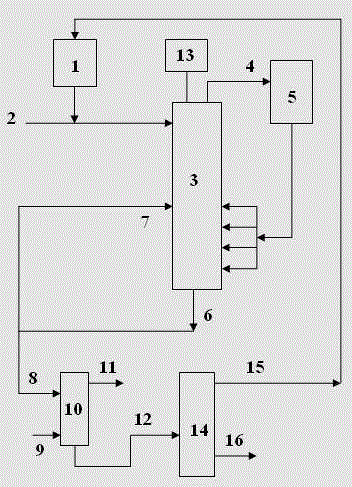

Method used

Image

Examples

Embodiment 1

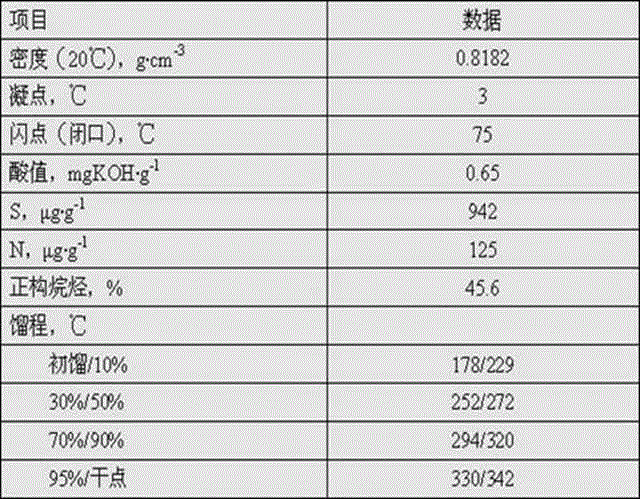

[0023] The raw material oil used in the present embodiment is the second-line distillate oil of Daqing, and the properties of the raw material are beneficial to Table 1, and the cooling medium is one of the urine composition isopropanol, and the urine composition and reaction process conditions are as Table 2 and Table 3,

[0024] The washing oil is distillate oil with a distillation range of 120-160 DEG C, and the complex is washed under the final temperature condition of the complex reaction. Then the complex is heated to 60-70°C to decompose into wax liquid and urine, the wax liquid is washed with water, and the urine is circulated back to the urine tank. The specific results are shown in Table 4.

[0025] Table 1 Raw Oil Properties

[0026]

[0027] Table 2 Composition of isopropanol urine solution

[0028]

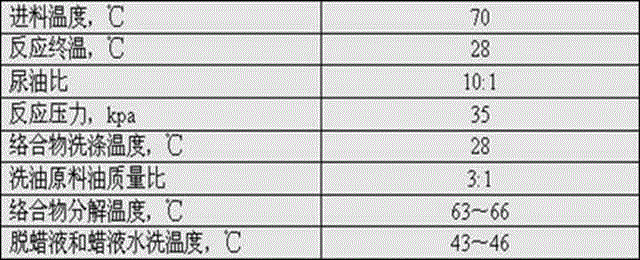

[0029] Table 3 reaction process conditions

[0030]

[0031] Table 4 embodiment result

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com