Vanadinizing timing chain for engine

An engine and chain technology, applied in the field of auto parts manufacturing, can solve the problems of heat resistance and oxidation resistance, poor corrosion resistance, short service life, etc., and achieve the effect of improving static strength, corrosion resistance and fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

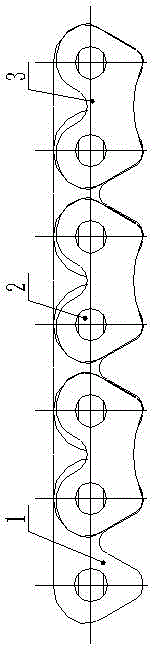

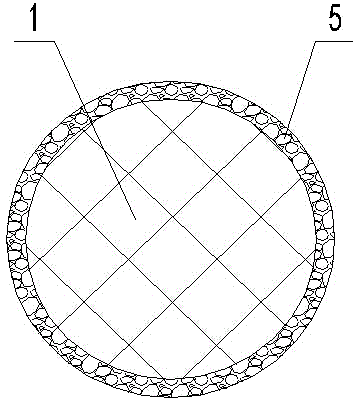

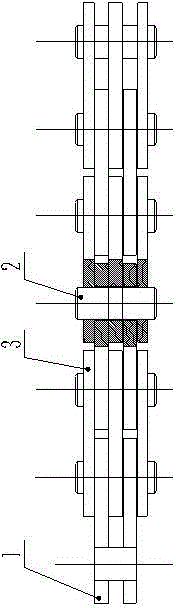

[0012] Embodiment 1: with reference to attached Figure 1-4 . A vanadium-infiltrated timing chain for an engine comprises an engine timing chain, the chain pin 2 in the engine timing chain is a GCr15 pin and the surface layer of the GCr15 pin is a metallized layer 5; in the engine timing chain The shape of the chain plate 1 is tooth-shaped and the tooth-shaped meshing arc surface is a concave-convex tooth meshing surface 4 . The metal infiltrated layer 5 is a vanadium infiltrated layer. The guide plate 3 and the gear plate are respectively provided with two chain pin shaft holes with a pitch of 6.27-6.29 mm; the inner distance between the two inner chain plates of the chain links of the guide plate 3 is ≥ 3.1 mm. The increase rate of the two ends of the chain pin 2 protruding from the guide plate 3 is not less than 3%, and the enlarged diameter is ≥ 2.47 mm; the length of the protruding part is ≥ 0.65 mm; the periphery of the enlarged part is angular And the angle between t...

Embodiment 2

[0013] Embodiment 2: On the basis of Embodiment 1, the metal infiltrated layer 5 is a vanadium infiltrated layer, which has high reliable heat resistance, wear resistance, oxidation resistance and corrosion resistance, and can adapt to different environments respectively Medium, so that the service life of the chain pin has been improved several times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com