Method for quickly analyzing total iron in iron ore

A rapid analysis, iron ore technology, applied in the direction of material analysis by observing the effect of chemical indicators, and analysis by chemical reaction of the material, etc., can solve the observation and matching of the end point from purple to bright yellow. The problem of slow response speed, high measurement results, etc., achieves the effect of easy observation, good accuracy and precision, and improved operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

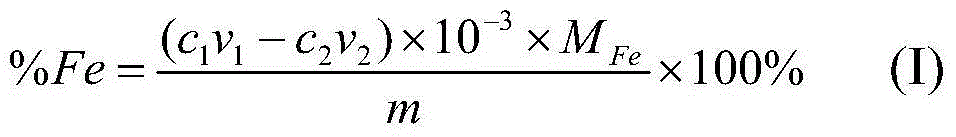

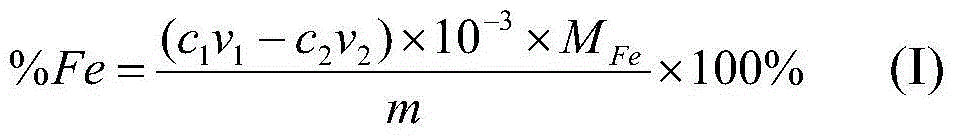

Method used

Image

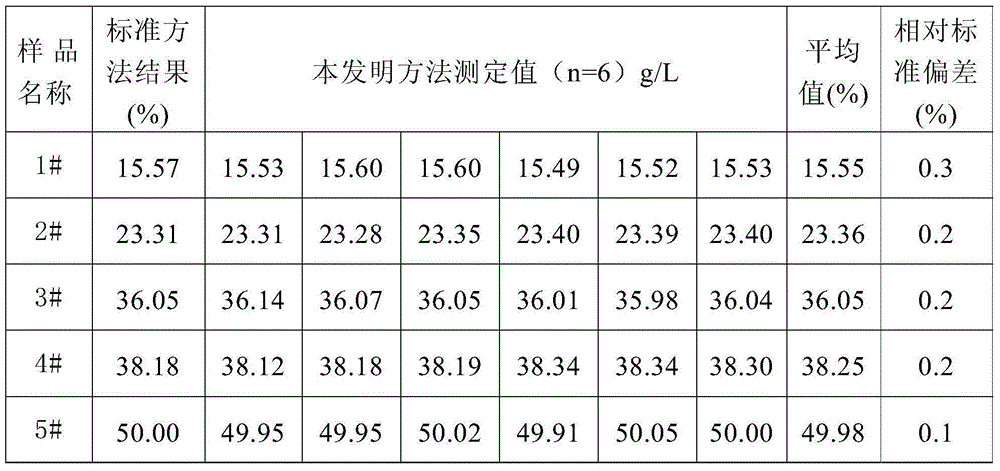

Examples

Embodiment 1

[0034] (1) Preparation of reagents

[0035] Reagents used in this and the following examples include:

[0036] (1) Ammonia solution: a solution of ammonia and water in a volume ratio of 1:1;

[0037] (2) Nitric acid solution: a solution prepared with concentrated nitric acid and water at a volume ratio of 1:1;

[0038] (3) Sulfosalicylic acid indicator: 20% aqueous solution of sulfosalicylic acid;

[0039] (4) Xylenol orange indicator: an aqueous solution with a mass concentration of xylenol orange of 0.5%;

[0040] (5) EDTA standard solution: EDTA concentration is 0.0300mol / L;

[0041] (6) Bismuth nitrate standard solution: the concentration of bismuth nitrate is 0.0300mol / L.

[0042] (2) Analysis steps

[0043] Weigh 0.1656g of iron ore sample into a glass beaker, decompose the sample with a mixed acid consisting of 20mL of concentrated hydrochloric acid, 10mL of concentrated nitric acid and 5mL of concentrated sulfuric acid. After the fumes of sulfuric acid are exhaust...

Embodiment 2

[0047] Weigh 0.2878g of iron ore sample into a glass beaker, decompose the sample with a mixed acid consisting of 20mL of concentrated hydrochloric acid, 10mL of concentrated nitric acid and 5mL of concentrated sulfuric acid. Transfer to a 100mL volumetric flask, add water to make up to 100mL. Dispense 25.00 mL of the test solution into a glass beaker, add ammonia solution dropwise until ferric hydroxide precipitates, add nitric acid solution dropwise until the ferric hydroxide precipitate dissolves, add 1 mL in excess, and dilute with water to 100 mL. Add 5 drops of sulfosalicylic acid indicator solution with a mass concentration of 20%, drip with 0.0300mol / LEDTA standard solution at room temperature until the red color disappears, and then excess 3-5mL to consume a total of 20.00mL of EDTA standard solution. Add 3 drops of xylenol orange indicator solution with a mass concentration of 0.5%, and use 0.0300mol / L bismuth nitrate standard solution to drop from yellow to orange r...

Embodiment 3

[0049] Weigh 0.2697g of iron ore sample in a glass beaker, decompose the sample with a mixed acid consisting of 20mL of concentrated hydrochloric acid, 10mL of concentrated nitric acid and 5mL of concentrated sulfuric acid. Transfer to a 100mL volumetric flask and add water to make up to 100mL. Dispense 25.00 mL of the test solution into a glass beaker, add ammonia solution dropwise until ferric hydroxide precipitates, add nitric acid solution dropwise until the ferric hydroxide precipitate dissolves, add 1 mL in excess, and dilute with water to 100 mL. Add 5 drops of sulfosalicylic acid indicator solution with a mass concentration of 20%, drip with 0.0300mol / L EDTA standard solution at room temperature until the red color disappears, and then excess 3-5mL to consume a total of 25.00mL of EDTA standard solution. Add 3 drops of xylenol orange indicator solution with a mass concentration of 0.5%, use 0.0300mol / L bismuth nitrate standard solution to drop from yellow to orange red, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com