Hierarchical pore structure silicon-based negative electrode material for lithium battery and preparation method of hierarchical pore structure silicon-based negative electrode material

A technology of silicon-based negative electrode materials and silicon-based materials, applied in battery electrodes, structural parts, circuits, etc., can solve problems such as difficulty in large-scale production, high cost of raw materials, high cost, etc., to achieve improved conductivity, increased coverage area, The effect of mitigating the volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

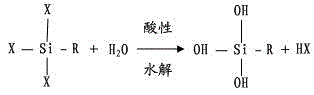

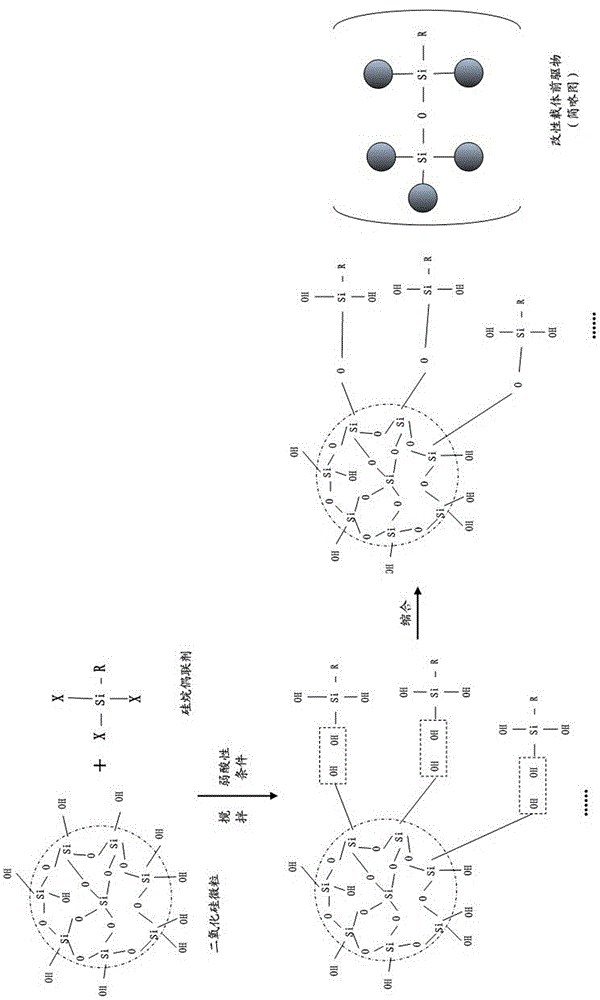

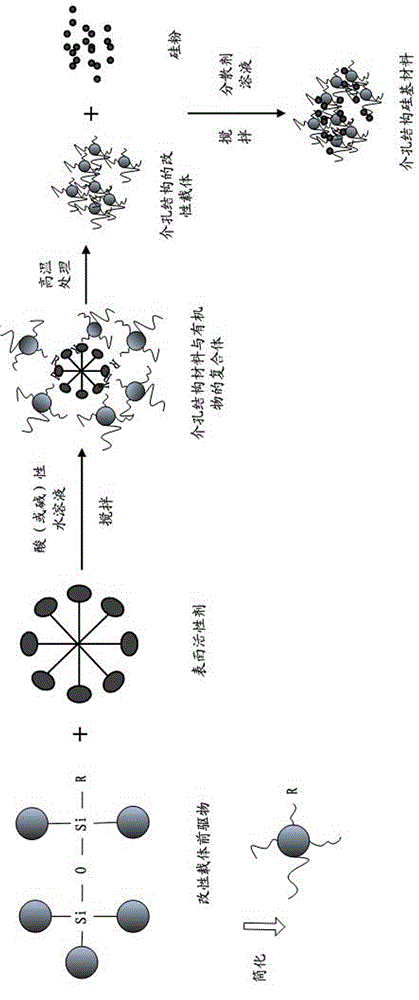

Method used

Image

Examples

Embodiment 1

[0050] (1) The silicon dioxide powder waste produced by the vapor deposition method in optical fiber production is subjected to pickling pretreatment. Add it into hydrochloric acid with a concentration of 8% to soak to remove impurities, stir for 2 hours, filter with deionized water to wash and filter repeatedly, and finally dry the filtered product.

[0051] (2) Take 5g of purified silica powder and add it to deionized water to disperse. Use the water bath method to heat up. The temperature of the water bath is controlled at 30°C. Stir magnetically for 1h, add 0.05g of silane coupling agent, and add acetic acid to make the solution The pH value of the mixture was controlled at 4, and stirred for 2 hours to obtain the precursor of the modified carrier. Then add 0.15g of sodium lignosulfonate surfactant, and add acetic acid to control the pH value of the solution to 4, magnetically stir for 2h, and then carry out crystallization treatment at 50°C after standing, deionized washi...

Embodiment 2

[0055] (1) Obtain purified silica powder according to Example 1.

[0056] (2) Take 10g of purified silica powder and add it to deionized water to disperse. Use the water bath method to heat. The pH value of the mixture was controlled at 4, and stirred for 2 hours to obtain the precursor of the modified carrier. Then add 0.4g fatty acid glyceride and sodium dodecylbenzenesulfonate to mix the active agent, and add oxalic acid to control the pH value of the solution to 4, stir magnetically for 2 hours, and carry out crystallization treatment at a temperature of 100°C after standing still. Ion washing, filtering and drying. Then, the filtered product is calcined at a high temperature in air at 500° C. to finally obtain a modified carrier with a honeycomb mesoporous structure.

[0057] (3) Take 10g of the modified carrier material and add it to the ethanol solution, then add 10g of silicon powder (with a particle size distribution of 5-30um), stir magnetically for 2 hours to disp...

Embodiment 3

[0060] (1) Obtain purified silica powder according to Example 1.

[0061] (2) Take 10g of purified silica powder and add it to deionized water to disperse. Use the water bath method to heat up. The temperature of the water bath is controlled at 55°C. Stir magnetically for 1h. Add 0.15g of silane coupling agent and oxalic acid to make the solution The pH value of the mixture was controlled at 4, and stirred for 2 hours to obtain the precursor of the modified carrier. Then add 0.4 g sodium alkylbenzene sulfonate active agent, and add NaOH to control the pH value of the solution to 13, ultrasonically vibrate for 2 hours, and then carry out crystallization treatment at 150° C. after standing, deionized washing, filtering, and drying. Then, the filtered product is calcined at a high temperature in air at 500° C. to finally obtain a modified carrier with a honeycomb mesoporous structure.

[0062] (3) Take 5g of the modified carrier material and add it to the ethanol solution, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com