Positive pole material of lithium ion battery and preparation method of positive pole material

A lithium-ion battery and cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as electrochemical performance that needs to be improved qualitatively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

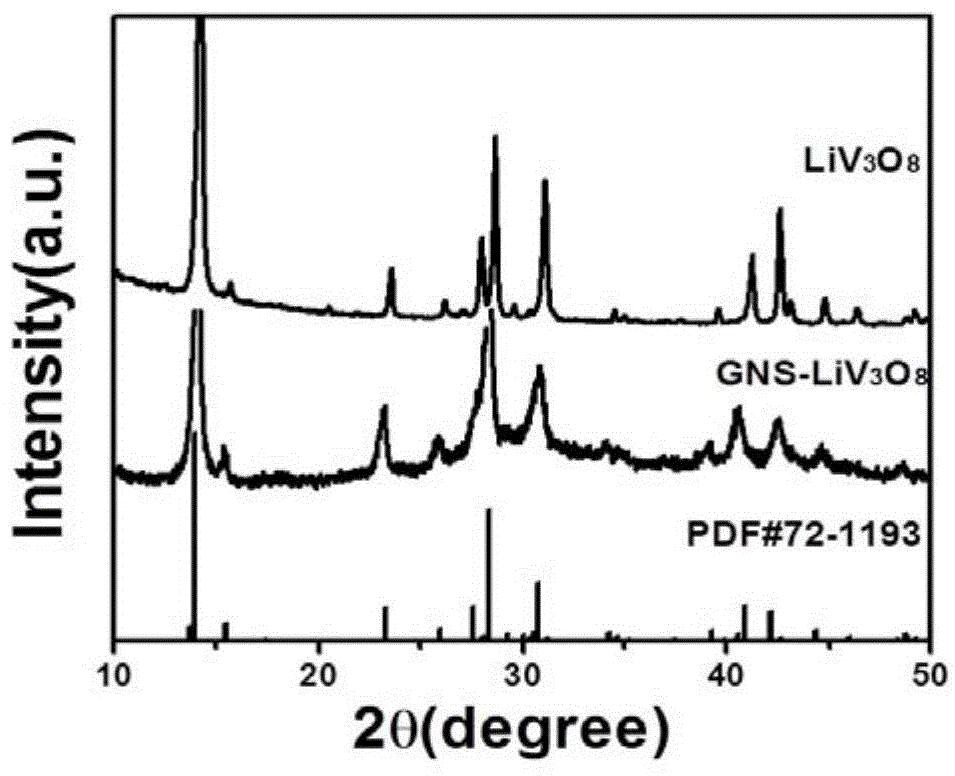

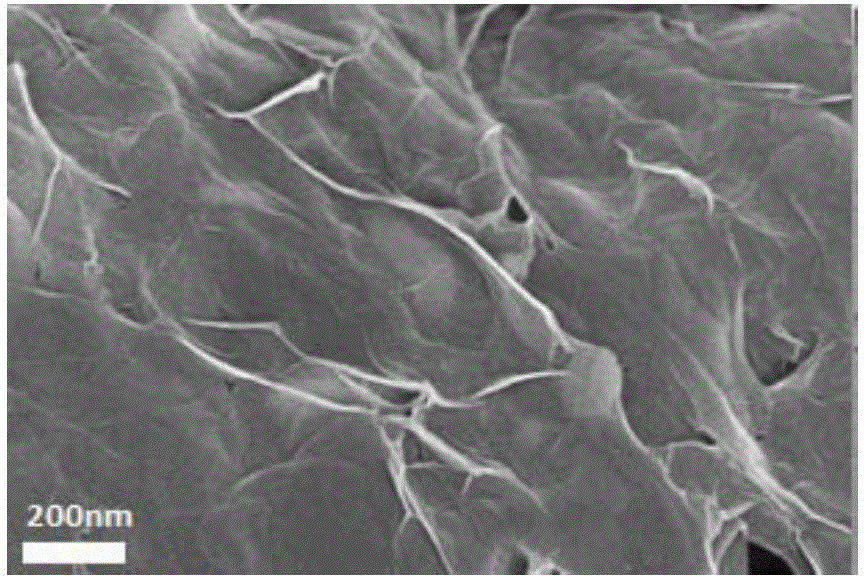

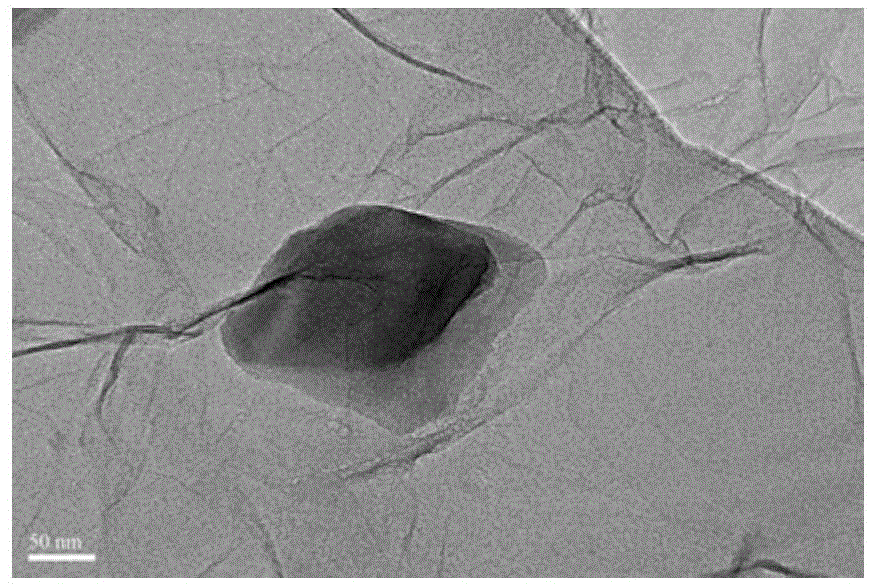

[0030] Step 1: Add 2.28g of oxalic acid to 70mL of aqueous solution dispersed with 2.55g of ammonium metavanadate, stir until the solution is brownish yellow, transfer the brownish yellow solution to a 100mL autoclave, place it in an oven, 180 °C for 12 hours, and after suction filtration, the sample was dried in an oven at 80 °C for 12 hours, and the precursor (NH 4 ) 5 V 2 o 5 . 1g of precursor ((NH 4 )5 V 2 o 5 Dissolve in 300mL aqueous solution, add 0.17g lithium hydroxide monohydrate to the solution, then add 0.2g polyethylene glycol 4000 as a dispersant, stir at room temperature for 2 hours, then heat in an oil bath at 80°C until the solvent evaporates to dryness. The obtained samples were calcined at 450 °C in an air atmosphere for 8 h to obtain crystallized LiV 3 o 8 Nanosheets.

[0031] The second step, weigh 0.5g LiV 3 o 8 , dissolved in 50mL of toluene solution, sonicated for 30min at 300w power, LiV 3 o 8 The dispersion of the nanosheets is better, and...

Embodiment 2

[0033] Step 1: Add 2.28g of oxalic acid to 70mL of aqueous solution dispersed with 2.55g of ammonium metavanadate, stir until the solution is brownish yellow, transfer the brownish yellow solution to a 100mL autoclave, place it in an oven, 180 °C for 12 hours, and after suction filtration, the sample was dried in an oven at 80 °C for 12 hours, and the precursor (NH 4 ) 5 V 2 o 5 . 1g of precursor (NH 4 ) 5 V 2 o 5 Dissolve in 300mL aqueous solution, add 0.17g lithium hydroxide monohydrate to the solution, then add 0.2g polyvinylpyrrolidone as a dispersant, stir at room temperature for 2 hours, then heat in an oil bath at 80°C until the solvent evaporates to dryness. The obtained samples were calcined at 450 °C in an air atmosphere for 8 h to obtain crystallized LiV 3 o 8 Nanosheets.

[0034] The second step, weigh 0.5g LiV 3 o 8 , dissolved in 50mL of toluene solution, sonicated for 30min at 300w power, LiV 3 o 8 The dispersion of the nanosheets is better, and th...

Embodiment 3

[0036] Step 1: Add 2.28g of oxalic acid to 70mL of aqueous solution dispersed with 2.55g of ammonium metavanadate, stir until the solution is brownish yellow, transfer the brownish yellow solution to a 100mL autoclave, place it in an oven, 180 °C for 12 hours, and after suction filtration, the sample was dried in an oven at 80 °C for 12 hours, and the precursor (NH 4 ) 5 V 2 o 5 . 1g of precursor (NH 4 ) 5 V 2 o 5 Dissolve in 300mL aqueous solution, add 0.17g lithium hydroxide monohydrate to the solution, then add 0.2g polyethylene glycol 4000 as a dispersant, stir at room temperature for 2 hours, then heat in an oil bath at 80°C until the solvent evaporates to dryness. The obtained samples were calcined at 450 °C in an air atmosphere for 8 h to obtain crystallized LiV 3 o 8 Nanosheets.

[0037] The second step, weigh 0.5g LiV 3 o 8 , dissolved in 50mL of toluene solution, sonicated for 30min at 300w power, LiV 3 o 8 The dispersion of the nanosheets is better, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com