Bipolar current collector and preparation method thereof

A current collector, bipolar technology, applied in the direction of electrode carrier/current collector, electrolyte battery manufacturing, non-aqueous electrolyte battery, etc. problems, to reduce the influence of the weakening of the electrical conductivity, prevent the short circuit of the battery, and reduce the surface contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

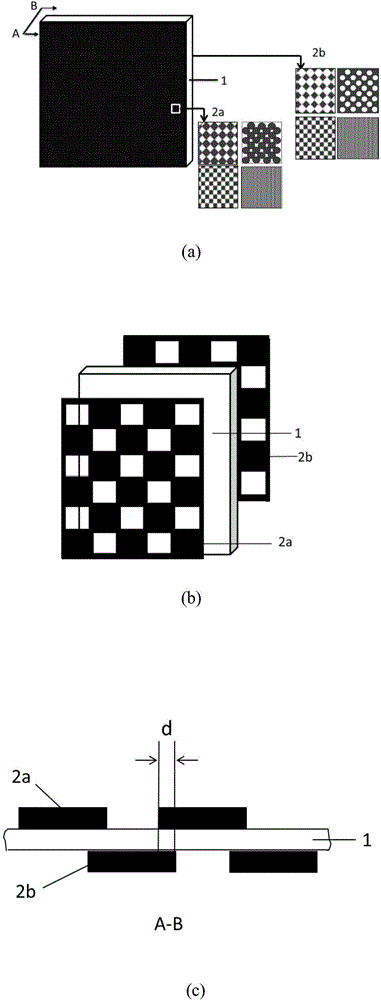

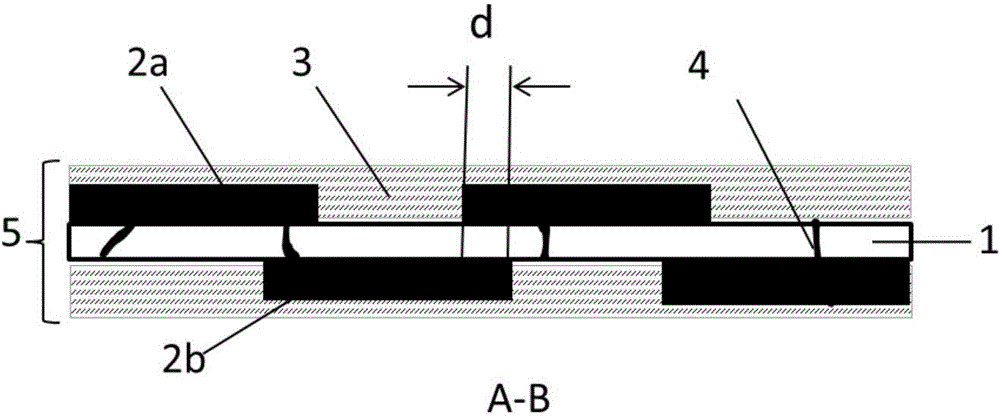

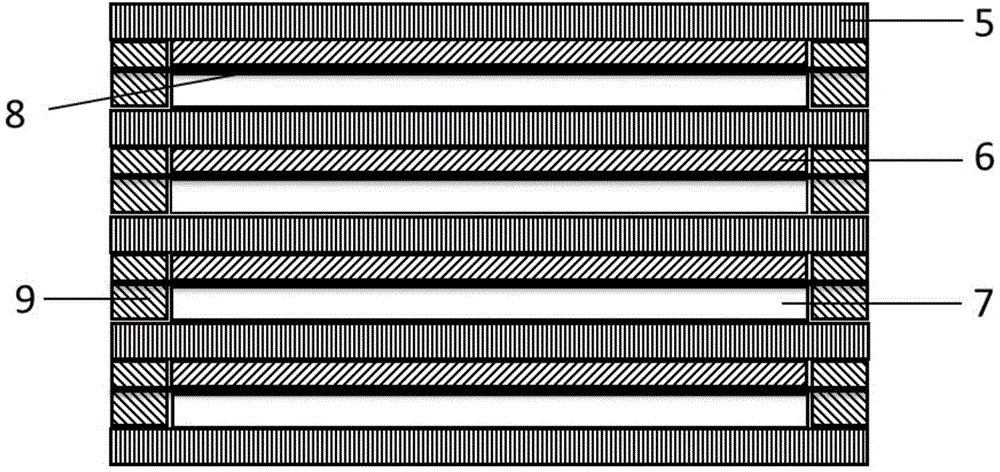

[0034] In this embodiment, the bipolar current collector includes: the conductive matrix film 1 is a polymer composite conductive film composed of conductive fillers and polymer matrix materials; the polymer barrier film layers 2a and 2b are made of polyvinylidene fluoride; the conductive shunt layer 3 Composite coating of carbon black and polyvinylidene fluoride is used.

[0035] The preparation method of the bipolar current collector of the present embodiment is as follows:

[0036] 1) Pretreatment of the conductive substrate film:

[0037] Take a polymer composite conductive film with a thickness of 35 μm, cut it into A4 paper size, spray and clean the surface of the polymer composite conductive film with deionized water and ethanol respectively, remove dust and oil on the surface, and dry it with hot air for 1 min.

[0038] 2) Print the polymer barrier film layer:

[0039] a. Ink preparation for polymer barrier film layer printing: in terms of mass percentage: polyvinyl...

Embodiment 2

[0044] In this embodiment, the bipolar current collector includes: the conductive matrix film 1 adopts a polymer composite conductive film composed of a conductive filler and a polymer matrix material; the polymer barrier layers 2a and 2b adopt polyaniline; the conductive shunt layer 3 adopts carbon black and polyvinylidene fluoride composite coating.

[0045] In the preparation process of the bipolar current collector, the polymer barrier layer adopts the conductive polymer polyaniline. Its ink formula: all use mass percentage, 0.125g polyaniline / 20ml 1% sulfuric acid solution, humectant glycerol 5%, 1% OP-10 aqueous solution 2%, stir at room temperature for 4h, ultrasonic treatment for 30min, and multi-stage filtration Impurities with a particle size greater than 0.2 μm are removed to obtain printing ink. All the other are identical with embodiment 1 preparation method

Embodiment 3

[0047] In this embodiment, the bipolar current collector includes: the conductive matrix film 1 is a polymer composite conductive film composed of conductive fillers and polymer matrix materials; the polymer barrier layers 2a and 2b are made of polystyrene; the conductive shunt layer 3 is made of carbon Black and polyvinylidene fluoride composite coating.

[0048] In the preparation process of the bipolar current collector, the polymer barrier layer is made of polystyrene, and its ink formula: all use mass percentage, polystyrene 2%, humectant glycerin 5%, 1% OP-10 aqueous solution 2% , the remaining amount of toluene, stirred at room temperature for 4 hours, ultrasonically treated for 30 minutes, and removed impurities with a particle size greater than 0.2 μm by multi-stage filtration to obtain printing ink. All the other preparation methods are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com