Intermediate infrared laser device with tunable inner cavity OPO

A laser and infrared technology, applied in the direction of lasers, laser parts, phonon exciters, etc., can solve the problems of limiting infrared lasers, complex systems, large volume, etc., to improve light-to-light conversion efficiency, increase heat dissipation efficiency, and compact structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

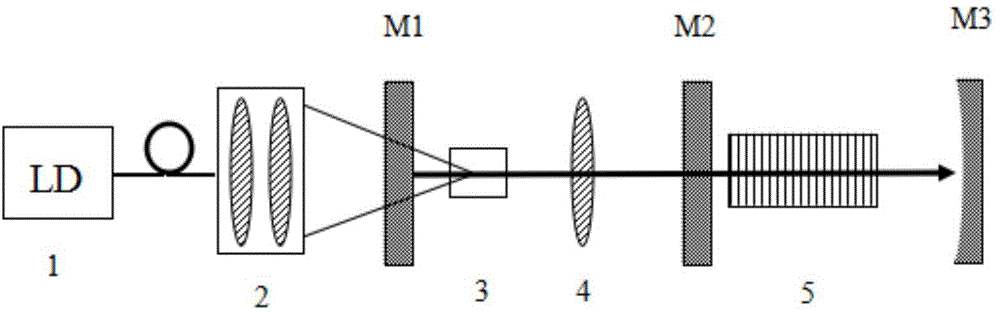

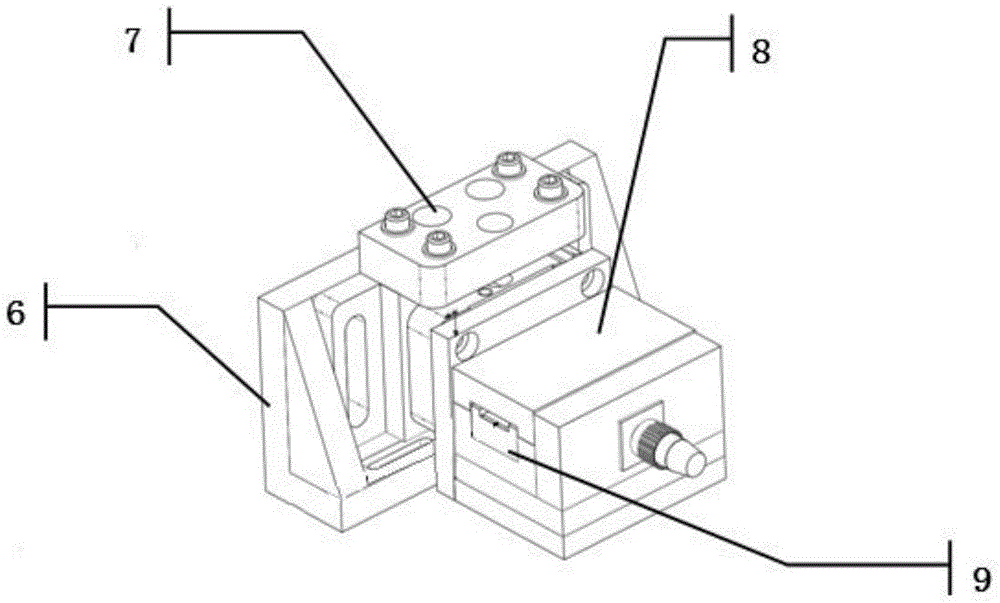

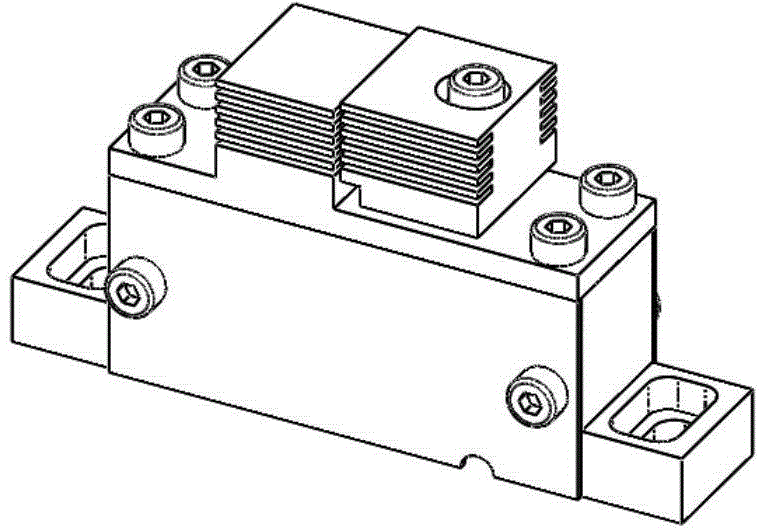

[0025] Such as figure 1 The schematic diagram of the optical path structure of the present invention shown: including LD semiconductor pumping source 1, fiber coupling system 2, laser gain crystal 3, air-cooled heat dissipation device, crystal temperature control furnace, coating cavity mirror and periodically polarized crystal 5; coating cavity The mirror constitutes the resonant cavity of the inner cavity OPO tunable mid-infrared laser; the coated cavity mirror includes a front cavity mirror plane mirror M1, an intracavity focusing lens 4, an OPO front cavity mirror flat mirror M2 and a rear cavity mirror M3; the LD semiconductor pump The light source generated by Puyuan 1 is coupled and output by the optical fiber coupling system 2, and the front cavity mirror plane mirror M1, the laser gain crystal 3, the intracavity focusing lens 4, and the OPO front cavity mirror...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com